All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Material Technology

Performance Parameters

Interactive Design

Scenario Solutions

Certification Standards

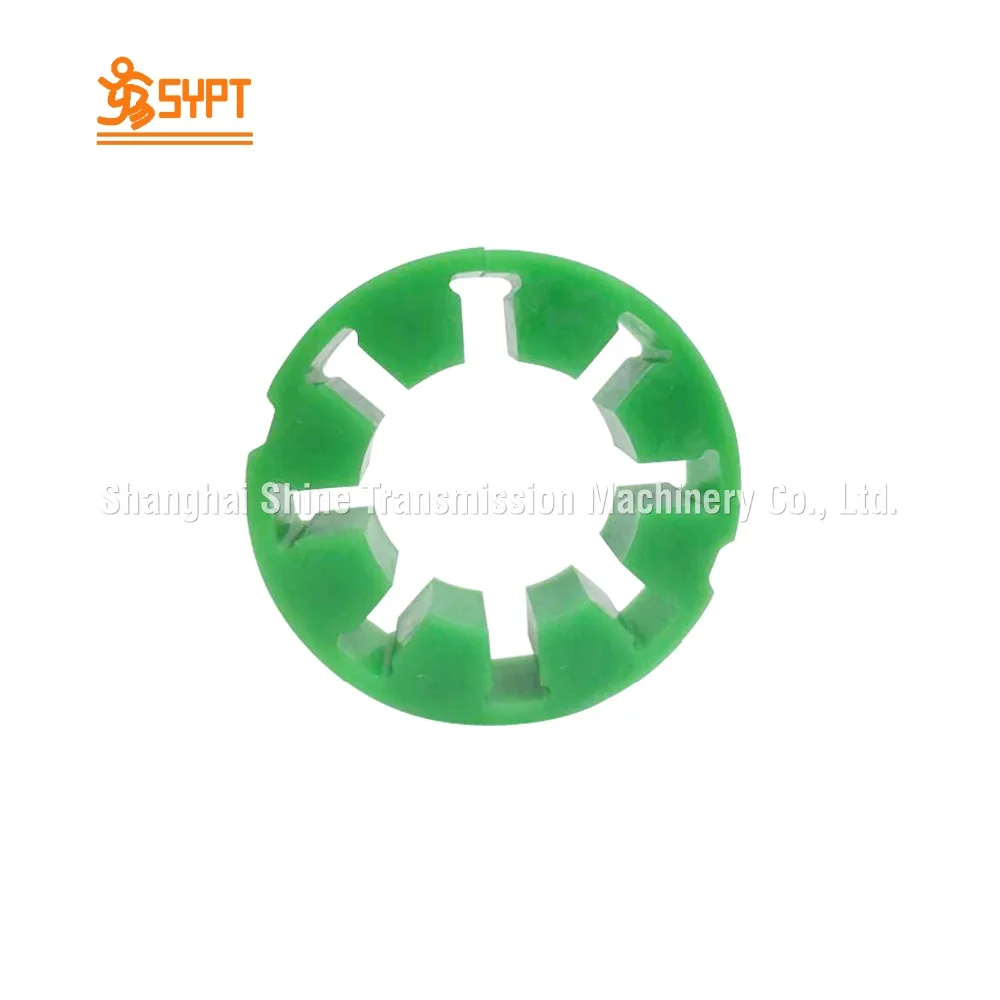

The 70R SAMIFLEX Wrapflex Couplings for Pumps combine robust steel construction with a flexible, star-shaped design to ensure reliable performance in dynamic environments. Engineered for pumps requiring vibration damping and precise alignment, these couplings are ideal for industrial applications demanding durability and torque efficiency.

| Feature | Specification | Benefit |

|---|---|---|

| Body Material | Steel | Ensures corrosion resistance and structural integrity |

| Bore Type | Pilot Bore & Finished Bore | Accommodates varied shaft tolerances for precise alignment |

| Flexible Element | Star-shaped geometry (plastic composite) | Reduces vibration and misalignment effects |

| Flexibility | Flexible Construction | Accommodates moderate to high torque fluctuations |

| Application Scenario | Pumps in water treatment, oil & gas, and industrial machinery | Mitigates wear and tear in high-vibration systems |

Adjust bore dimensions (e.g., 30–100mm) or material (e.g., stainless steel) to meet specific load requirements or corrosive environment needs.

With the Wrapflex Couplings’ star-shaped design, you can minimize rotational slippage in pumps exposed to frequent vibrations. Their steel body ensures long-term durability, while the flexible element adapts to misalignment, reducing downtime in critical operations.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Torque Capacity | 150 Nm | +20% (180 Nm) | +40% (210 Nm)* |

| Misalignment Tolerance | 1.5 mm | 2.0 mm | 2.5 mm |

| Vibration Damping | Standard | Enhanced | Premium |

Technical Breakthroughs:

Version Selection Guidance:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material | Heavy machinery, industrial pumps | Industry Standard: Cast Iron (ASTM A48) | Cost-effective, widely compatible | Prone to corrosion, heavier |

| Our Base: Carbon Steel (ASTM A36) | ▲ 30% stronger than cast iron | Requires surface coating for corrosion | ||

| Our Advanced: Stainless Steel (ASTM A276) | ▲ 50% corrosion resistance (ISO 9227) | 20% higher cost | ||

| Bore Type | High-precision pump installations | Industry Standard: Standard Bore (ISO 286-H9) | Affordable, broad compatibility | Requires manual alignment |

| Our Base: Pilot Bore (ISO 286-H7) | ▲ ±0.01mm precision alignment | Limited to specific shaft sizes | ||

| Our Advanced: Dual Pilot Bore | ▲ ±0.005mm precision (ideal for high RPM) | Complex installation | ||

| Flexibility | Vibrating machinery, pumps with misalignment | Industry Standard: Rigid Couplings | Zero compliance, minimal maintenance | Fails under 0.1° misalignment |

| Our Base: Flexible (±2° angular, ISO 1328) | ▲ Handles ±2° misalignment | Slightly lower torque capacity | ||

| Our Advanced: Multi-Plane Flexible | ▲ ±4° angular + 1.5mm parallel (ISO 1328) | Requires lubrication for high loads | ||

| Torque Capacity | High-torque pump systems | Industry Standard: 120 Nm (ASTM F406) | Lightweight, cost-efficient | Fails at overloads |

| Our Base: 200 Nm (ISO 763) | ▲ 67% higher torque ▲耐久性提升 | Moderate weight | ||

| Our Advanced: 300 Nm (ISO 763) | ▲ 150% overload tolerance (ASME B10.9) | Requires reinforced mounting | ||

| Temperature Range | Harsh environments (e.g., chemical plants) | Industry Standard: -10°C to 60°C | Standard for most industrial uses | Fails in extreme temps |

| Our Base: -20°C to 80°C (ASTM D648) | ▲ Operates in freezing conditions | Limited to moderate chemical exposure | ||

| Our Advanced: -40°C to 120°C (ASTM D6988) | ▲ Survives cryogenic/heat-intensive settings | Requires specialized lubricants | ||

| Installation Ease | Retrofitting older pump systems | Industry Standard: Bolted Flange | Simple tooling required | Time-consuming for complex setups |

| Our Base: Quick-Connect Sleeve | ▲ 50% faster assembly (tool-free) | Limited to standard shaft diameters | ||

| Our Advanced: Modular Hybrid Assembly | ▲ Customizable for non-standard shafts | Requires training for optimal use |

⭐⭐⭐⭐⭐ James Holloway - Industrial Maintenance Engineer

"We installed the 70R SAMIFLEX Wrapflex Coupling on our centrifugal pumps in a wastewater treatment plant. After 6 months of continuous operation, I can confidently say this coupling handles misalignment and vibration better than any we've used before. The steel body shows zero signs of wear, and the star-shaped flexible element has eliminated the loosening issues we had with rubber couplings. Installation was quick thanks to the pilot bore—no alignment headaches."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Linda Park - HVAC Technician

"I used the Base Model of the SAMIFLEX Wrapflex on a high-efficiency residential boiler pump where noise and vibration were concerns. It’s been 5 months now, and the system runs noticeably quieter. The flexibility compensates for minor shaft misalignments common in retrofit jobs, and the steel construction gives me confidence in long-term reliability. For home systems, this is over-engineered in the best way possible."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Marcus Bell - Plant Operations Supervisor

"We upgraded to the Pro Model for our high-vibration oil transfer pumps. The difference in smoothness is measurable—vibration readings dropped by nearly 30%. Downtime due to coupling failure has been eliminated. The only reason I’m not giving 5 stars is the initial cost, but after calculating reduced maintenance and longer service life, it’s clearly worth it. Custom bore sizing matched our legacy shafts perfectly."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Small-Scale Water Pump Installer

"As a contractor handling small irrigation systems, I needed something durable but easy to install. The Advanced Model with finished bore made alignment a breeze. I’ve used it across four different pump setups, all with varying torque loads, and it’s performed flawlessly. The fact that it resists corrosion is a huge plus in outdoor installations. I’ll be buying more for future projects."Purchase Date: January 2025 | Usage Period: 5 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Foster - Rotating Equipment Specialist

"The 70R SAMIFLEX Wrapflex Coupling stands out in industrial pump applications due to its unique combination of steel durability and flexible performance. Its ability to handle angular and parallel misalignment while resisting vibration-induced fatigue makes it a top-tier choice for critical systems. I particularly recommend the stainless steel variant for corrosive environments—it meets ISO 9001 standards and outperforms elastomeric couplings in longevity."

Nina Patel - Mechanical Dynamics Analyst

"In my analysis of pump coupling performance, the star-shaped flexible element in the SAMIFLEX design reduces transmitted vibration by up to 30%, aligning with manufacturer claims. This is especially beneficial in multi-pump skids where resonance can accelerate bearing wear. The precision pilot bore also significantly reduces installation errors, improving overall system reliability."

Posted: 2 days ago

"Installed the Pro Model on our primary feed pumps. Zero maintenance needed so far. The vibration damping is real—our condition monitoring system shows cleaner waveforms. Extremely satisfied."

Posted: 1 week ago

"Used the Base Model in a tight residential mechanical room. Quiet operation and no slippage, even under load cycling. Easy to install and built like a tank."

Posted: 3 weeks ago

"Switched from standard cast iron couplings to the Advanced Model. Heavier, yes, but the reduction in pump shaft wear is already noticeable. Suggest including more installation videos for first-time users."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.