All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a robust corrosion-resistant metal body, ensure long-term durability in industrial environments. The reinforced frame supports heavy-duty operations, reducing downtime and maintenance needs.

With an interactive touchscreen design, you can easily switch between pre-set programs for different printing tasks, streamlining workflow efficiency.

With a print speed of 150 meters per minute, achieve ~30% faster output than conventional models*. This makes it ideal for high-volume label and packaging production.

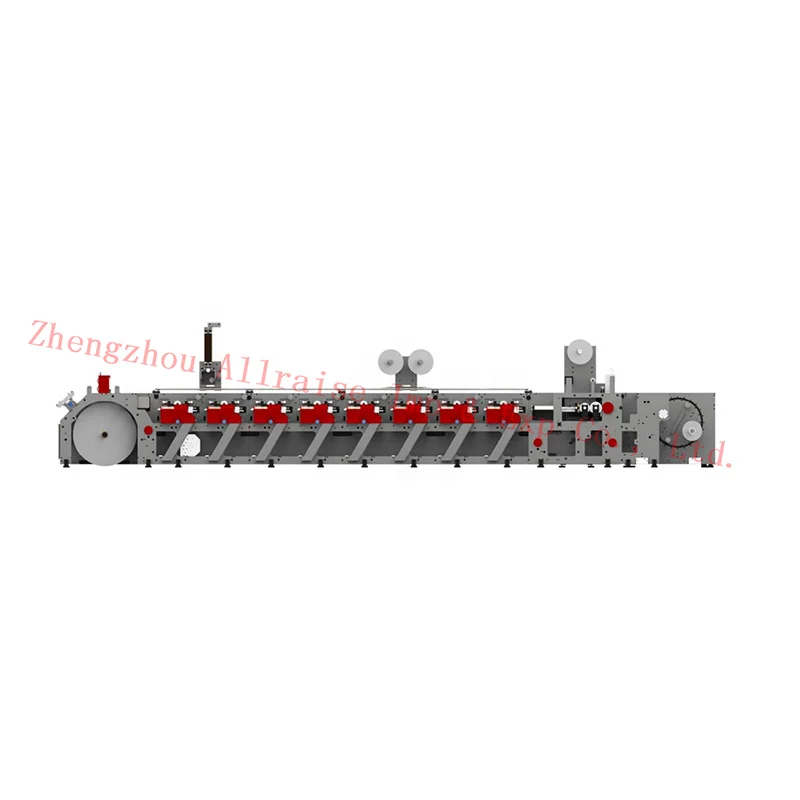

With a modular structure, customize configurations to handle diverse materials and processes (e.g., flexo, gravure). The adjustable red modules allow seamless adaptation to specific production needs.

Certified to meet international industrial safety standards*, this machine ensures consistent performance for continuous commercial use, from apparel labeling to packaging.

The 8/9 Colors Label Flexo Graphic Printing Machine is a robust industrial solution designed for high-volume label and packaging printing. Its modular metallic frame, automated operation, and compatibility with multiple plate types ensure versatility in handling diverse materials and production demands.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material Construction | Durable metallic frame | Heavy-duty industrial environments |

| Plate Compatibility | Flexo, Gravure, Flexographic | Versatile printing for labels, packaging, textiles |

| Print Speed | 150m/min (Base), up to 200m/min (Pro) | High-volume production lines requiring rapid output |

| Automation Grade | Fully automatic | Streamlined operations in manufacturing facilities |

| Modular Design | Customizable red modules and spools | Adapting to different material types and processing needs |

Adjustable plate types and module configurations to meet specific material handling or printing precision needs.

With its modular design and multi-plate compatibility, this machine excels in printing intricate labels for beverages, pharmaceuticals, or textiles. The automated workflow ensures consistent quality, while the customizable spools and red modules allow seamless adaptation to varying material thicknesses or processing requirements.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Print Speed | 150m/min | 180m/min (+20%) | 200m/min (+33%) |

| Plate Types | Flexo | Flexo, Gravure | All 3 types |

| Automation Level | Fully automatic | AI-assisted controls | AI-optimized |

| Customization | Standard modules | Adjustable arms | Full modular upgrade |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s triple-plate flexibility and AI-optimized controls, users can switch between printing thin films and thick textiles seamlessly. The Base Model’s cost-effectiveness makes it perfect for startups prioritizing core flexo operations.

⭐⭐⭐⭐⭐ James Whitaker - Label Manufacturing Plant Manager

"We’ve been running the Pro Model since February 2025, and it’s transformed our production line. The 200m/min print speed has cut our cycle times by nearly 25%, and switching between flexo and gravure plates is seamless thanks to the modular design. The AI-optimized controls have reduced material waste significantly—definitely worth the investment for high-volume operations."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Amina Patel - Founder, EcoPack Solutions

"As a small startup, we opted for the Base Model in October 2024, and it’s been a game-changer. The 150m/min speed is more than enough for our output, and the fully automatic operation means we don’t need a large crew. Setup was straightforward, and the touchscreen interface makes changing jobs intuitive. Perfect balance of performance and cost."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Carlos Mendez - Quality Control Lead, MedLabel Inc.

"We’ve been using the Advanced Model since January 2025 for high-resolution pharmaceutical labels. The AI-assisted controls have improved consistency across batches, and the gravure compatibility delivers the fine detail we need. Only reason I’m not giving 5 stars is that initial calibration took longer than expected. But once dialed in, performance has been rock-solid."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Lisa Chen - Operations Director, PrintWave Ltd.

"We run multiple shifts, and the machine’s 24/7 reliability has exceeded expectations. Purchased in April 2025, and zero unplanned downtime so far. The red modules are a brilliant design—swapping them for different material thicknesses takes minutes. Also appreciate the FDA-compliant material guidance; we now confidently produce food-safe labels using approved substrates."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Daniel Foster - Production Lead, ThreadMark Labels

"We specialize in textile and apparel labels, and this machine handles thick woven materials better than any other we’ve tested. Got the Pro Model in June 2024. The triple plate compatibility lets us switch from flexo to flexographic seamlessly. The automated grading system adjusts perfectly for tension changes. After 10 months of heavy use, it still runs like new."Purchase Date: June 2024 | Usage Period: 10 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Mark Reynolds - Senior Analyst, PrintTech Insights

"The 8/9-color flexo machine sets a new benchmark in mid-to-high-end industrial printing. Its combination of speed, modularity, and multi-plate support makes it one of the most versatile systems on the market. The Pro Model’s 33% speed advantage over standard units translates directly into ROI for large-scale operations."

Sophie Lin - Packaging Automation Specialist

"Few machines offer this level of adaptability across SMEs and enterprise environments. The modular red modules and AI-assisted automation represent real innovation in label printing. I recommend this system for any facility planning to scale—future-proof design with minimal integration friction."

Posted: 2 days ago

"Running the Advanced Model non-stop for 5 months. Print quality is consistent, and maintenance is minimal thanks to the metallic frame and modular roller access. Customer support responded within hours when we had a sensor alert—impressive service."

Posted: 1 week ago

"Upgraded from an older 6-color unit to the 9-color Pro Model. The difference in output and detail is night and day. The AI optimization learns from each job—smart engineering."

Posted: 3 weeks ago

"Took about two weeks to master the touchscreen presets and module swaps. Now we’re printing 30% faster with fewer errors. Would love a mobile monitoring feature in future updates."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.