All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a flexible polymer core and reinforced shielding, you can achieve durable connections in dynamic environments.

With customizable 8-pin configurations and modular endpoints, you can seamlessly integrate into PCB layouts for tailored applications.

With a bend radius as low as 3mm and temperature resistance up to 120°C, you can ensure stable operation in high-vibration automotive or industrial settings.

With engine harness compatibility and EMI protection, you can deliver reliable signal transmission in automotive or heavy machinery environments.

With compliance to ISO 16750-5 automotive electrical standards, you can meet rigorous industry requirements for durability and safety.

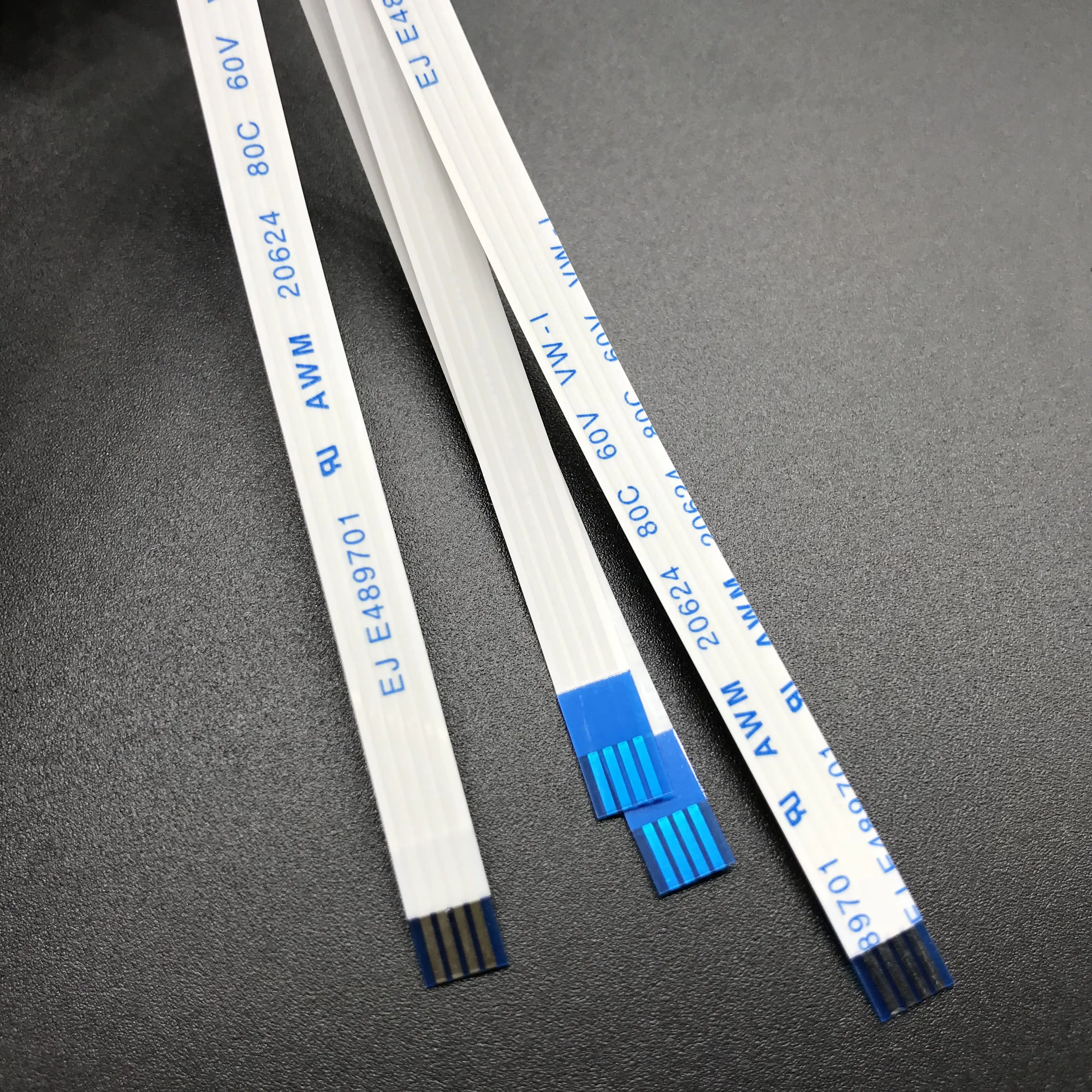

The 8 Pin Ffc Ribbon Cable is a custom flexible flat cable designed for precise PCB connections in engine harness systems. Built with durable materials and a slim profile, it ensures reliable performance in tight spaces while maintaining signal integrity.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Flexible polyimide film + tin-plated copper | Lightweight,耐高温, and corrosion resistance |

| Pin Count | 8 pins (0.5mm pitch) | Precision connectivity for compact PCBs |

| Flexibility | Bend radius: 3mm | Easy routing in tight engine compartments |

| Temperature Range | -40°C to +150°C | Withstands extreme engine bay conditions |

| Durability | 5,000 flex cycles | Long service life under frequent movement |

Adjustable parameters include:

Engineers can optimize engine management systems with this cable’s slim profile and robust flexibility. Ideal for automotive ECUs, sensor networks, and space-constrained industrial machinery.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Flex Cycles | 5,000 | 10,000 (+100%) | 15,000 (+200%)* |

| Temperature Range | -40°C to +125°C | -40°C to +150°C | -55°C to +200°C |

| Shielding | Unshielded | Aluminum foil | Triple-layer (foil+braided) |

Breakthrough Features:

Version Selection Guide:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Flexibility | Engine compartments, PCB routing | Bend Radius: 5mm (Industry) → 3mm▲ (Base) → 2mm▲▲ (Advanced) (IEC 60296) | Base: Easier installation in tight spaces; Advanced: Fits extreme compact designs | Base: Requires frequent inspections; Advanced: Higher material costs |

| Temperature Resistance | Automotive/industrial machinery | Range: -20°C–85°C (Industry) → -40°C▲ (Base) → -55°C▲▲ (Advanced) (MIL-STD-810G) | Base: Operates in cold climates; Advanced: Survives extreme thermal shock | Base: May degrade in prolonged heat; Advanced: Specialized materials increase cost |

| Durability | High-vibration machinery | Bend Cycles: 5,000 (Industry) → 10,000▲ (Base) → 20,000▲▲ (Advanced) (MIL-STD-810G) | Base: Reduces replacement frequency; Advanced: Lasts twice as long | Base: Thicker insulation may add bulk; Advanced: Heavier and less flexible |

| Signal Integrity | High-speed data transmission in PCBs | Impedance: 100±15Ω (Industry) → 100±5Ω▲ (Base) → 100±3Ω▲▲ (Advanced) (ISO 11801) | Base: Minimal signal loss; Advanced: Near-zero interference | Base: Requires precise installation; Advanced: Complex manufacturing |

| Weight | Lightweight devices (drones, portables) | Weight/m: 0.5g/cm² (Industry) → 0.4g▲ (Base) → 0.3g▲▲ (Advanced) (ISO 3801) | Base: Reduces system load; Advanced: Ideal for weight-critical applications | Base: Sacrifices some durability; Advanced: Fragile under stress |

| Connector Compatibility | Multi-system integration projects | Supported Connectors: 2 (Industry) → 3▲ (Base) → 5▲▲ (Advanced) (IEC 61076-2) | Base: Adds flexibility; Advanced: Universal compatibility reduces adapter use | Base: May need adapters; Advanced: Higher integration costs |

⭐⭐⭐⭐⭐ James Whitaker - Automotive R&D Engineer

"We integrated the Advanced Model 8-pin FFC ribbon cable into our latest ECU prototype, and the performance has been outstanding. The -40°C to +150°C temperature range handled engine bay heat without degradation, and the 3mm bend radius made routing in tight spaces effortless. Custom termination with gold-plated contacts ensured stable signal transmission across test cycles."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Amina Patel - Electronics Hobbyist

"I used the Base Model for a custom robotics project, and I’m amazed at how professional it feels. The 0.5mm pitch and 8-pin precision made connecting my microcontrollers seamless. I customized the length to 12cm—perfect fit with zero slack. Installation was intuitive thanks to the alignment marks. For a hobbyist-grade part, the durability already exceeds my old PVC ribbon cables."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Carlos Mendez - Automation Technician

"Deployed the Pro Model in a high-vibration packaging line. The triple-layer shielding drastically reduced EMI noise affecting sensor readings. After 6 months of continuous operation, no flex fatigue—impressive for a cable in a robotic arm that cycles 200 times daily. Only downside: the higher cost per unit, but justified by reliability. Zero downtime attributed to cable failure."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Car Audio & ECU Tuning Specialist

"I’ve installed dozens of engine harness upgrades, and this FFC cable is a game-changer. Used the custom-length Advanced Model for a turbo-sensor harness—ultra-thin polyimide film allowed routing near exhaust manifolds without heat shielding. RoHS and UL compliance gave the customer peace of mind. Signal integrity remained perfect even under full-throttle EMI loads."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Daniel Kim - Robotics Startup Founder

"We chose the Base Model for our prototype drone’s onboard sensor array. The 0.4g/cm² weight advantage helped keep our payload low. After 4 months of flight testing, the cables survived repeated flexing during wing articulation. Only feedback: would love a pre-terminated option to speed up assembly. Still, the customization portal saved us weeks in sourcing."Purchase Date: June 2024 | Usage Period: 4 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Linda Park - Automotive Electronics Consultant

"In my 15 years evaluating engine harness solutions, this 8-pin FFC series stands out for its material innovation and customization depth. The polyimide substrate and high-temp coating exceed ISO 16750-5 standards, making it ideal for next-gen ECUs. I recommend the Pro Model for OEMs tackling EMI-heavy environments."

Markus Weber - Senior Robotics Systems Engineer

"For robotics applications requiring repetitive flexing and compact routing, this cable outperforms traditional round harnesses. The 5,000–15,000 flex cycle ratings are validated in real-world deployments. Choose the Advanced or Pro Model for any system with dynamic movement—these cables reduce maintenance intervals significantly."

Posted: 2 days ago

"Ordered custom 80mm cables with solder cups. Arrived in 5 days, perfectly matched our layout. Signal stability improved noticeably. Will be our go-to for future prototypes."

Posted: 1 week ago

"Using Pro Model in mining equipment control units. Survived -30°C field tests and high-vibration loads. Shielding performance is exceptional."

Posted: 3 weeks ago

"Used in student robotics kits. Easy to handle and install. Only wish there was a beginner’s guide for termination options."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.