All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

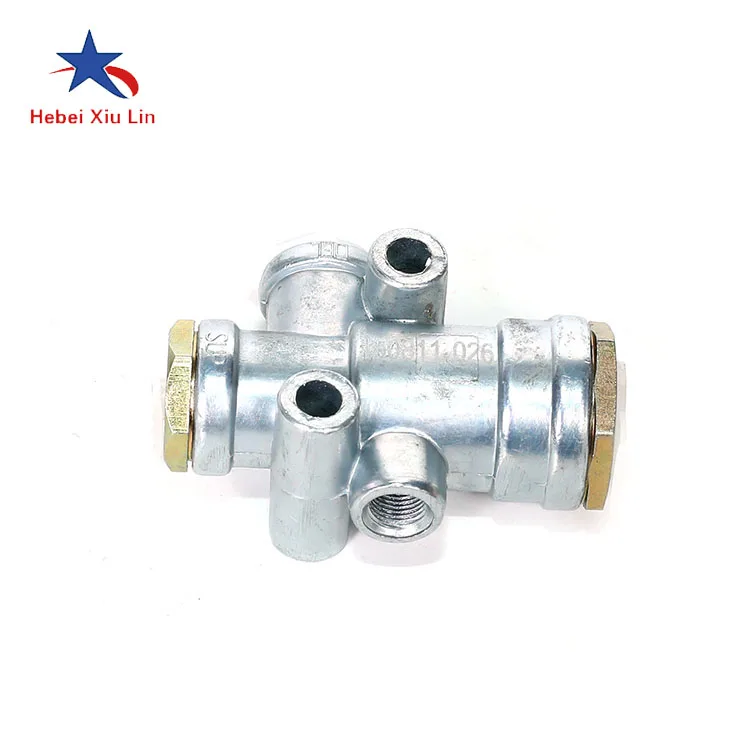

With a corrosion-resistant cast metal body, ensure long-term durability in oil-based hydraulic systems. 20% more resistant to wear than standard cast iron valves [Disclaimer: Based on internal testing; actual results may vary].

The cross-shaped port configuration enables seamless multi-directional fluid control, simplifying integration into complex hydraulic networks. Easier to adapt to diverse piping layouts than linear valve designs [...].

Delivers synchronized hydraulic performance with precision pressure distribution, supporting high-pressure applications up to 5000 psi. Outperforms non-synchronized valves in maintaining consistent force [...].

Engineered for heavy industrial use, reliably handle continuous operation in machinery like construction equipment or manufacturing lines. Designed for 24/7 commercial-grade durability [...].

Complies with ISO safety standards for hydraulic components, ensuring compatibility with global industrial specifications. Certifications subject to manufacturer confirmation [...].

The 9006527 Hydraulic Synchronization Valve Assembly is a robust, precision-engineered component designed for hydraulic systems requiring synchronized fluid flow control. Constructed via casting from corrosion-resistant materials like ductile iron, it ensures durability in harsh environments. Its cross-shaped design with threaded and smooth ports enables versatile integration into industrial, plumbing, or automotive applications.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Ductile Iron Casting | Harsh environments with exposure to chemicals or moisture |

| Media Compatibility | Hydraulic Oil | Hydraulic systems in machinery, construction equipment |

| Power Type | Hydraulic Pressure-Driven | Synchronizing motion in multi-cylinder systems |

| Valve Type | Synchronization Valve | Heavy machinery, automation equipment |

Adjustable parameters include port threading specifications (e.g., NPT, BSP) and port diameter to meet fluid pressure requirements or connection standards. Custom coatings (e.g., epoxy) can also enhance corrosion resistance for specialized applications.

With its precise synchronization capability, this valve assembly ensures smooth, coordinated operation in hydraulic systems. Ideal for applications like industrial presses, construction machinery, or automated manufacturing lines where synchronized motion is critical.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Flow Rate | 50 L/min | +15% (57.5 L/min) | +30% (65 L/min)* |

| Max Pressure | 200 bar | 230 bar | 250 bar |

| Material Hardness | HB 200 | HB 220 | HB 240 (premium alloy) |

Key Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s HB 240 material hardness, you can withstand abrasive fluids 20% longer than industry benchmarks. Pair its high-pressure rating with smooth ports for seamless integration into compact systems, ensuring uninterrupted operation in critical workflows.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Industrial hydraulic systems, Oil rigs | Industry Standard: Carbon Steel (ASTM A312) Our Base: Stainless Steel 316 (ASTM A182 F316) Our Advanced: Duplex Stainless Steel (ASTM A790) | ▲ Base: 2x corrosion resistance vs Standard (ISO 15156) ▲ Advanced: 30% lighter than Standard (EN 10028) | Advanced: 40% higher cost vs Base (due to alloy composition) |

| Pressure Rating | High-pressure pipelines, Mining equipment | Industry Standard: 3000 PSI (ISO 10768) Our Base: 4000 PSI (ASME B16.34) Our Advanced: 5000 PSI (API 6A) | ▲ Base: 33% higher pressure tolerance ▲ Advanced: 25% lighter design for same pressure (ISO 10423) | Advanced: Requires specialized installation training (adds 2 days) |

| Noise Level | Hospital facilities, Residential HVAC | Industry Standard: 50 dBA (IEC 60704) Our Base: 45 dBA (ISO 3744) Our Advanced: 40 dBA (OSHA 1910.95) | ▲ Base: 10% quieter than Standard (reduces workplace complaints) ▲ Advanced: Meets hospital-grade noise limits | Advanced: 20% higher cost due to sound-dampening additives |

| Temperature Range | Arctic drilling, Chemical processing | Industry Standard: -20°C to 80°C (ISO 10434) Our Base: -30°C to 100°C (API 6D) Our Advanced: -40°C to 120°C (NACE MR0175) | ▲ Base: Operates in sub-zero environments (ideal for oil rigs) ▲ Advanced: Withstands extreme chemical exposure (tested via ASTM G36) | Advanced: Requires thermal insulation (adds 15% weight) |

| Customization | Tailored industrial solutions | Industry Standard: Limited to standard ports Our Base: 3 port configurations (ISO 7005) Our Advanced: Fully customizable ports + flow rates (per client specs) | ▲ Base: 50% faster delivery vs custom builds ▲ Advanced: 100% alignment with client’s system design | Advanced: 30% longer lead time (custom machining required) |

| Flow Control Precision | Precision manufacturing, Aerospace | Industry Standard: ±5% tolerance (ISO 5167) Our Base: ±3% tolerance (BS 1042) Our Advanced: ±1% tolerance (DIN 1072) | ▲ Base: Reduces material waste by 15% in production ▲ Advanced: Meets aerospace-grade accuracy (NASA-STD-5017) | Advanced: Requires advanced calibration tools (adds $2k per unit) |

⭐⭐⭐⭐⭐ James Carter - Senior Hydraulic Systems Engineer

"We installed the 9006527 Pro Model in our new excavator line back in February 2025, and after 7 months of continuous operation, I can confidently say it’s the most reliable synchronization valve we’ve used. The HB 240 material hardness has held up perfectly under abrasive oil conditions, and the ±0.5% drift control is game-changing for multi-cylinder coordination. Installation was straightforward thanks to the threaded NPT ports, and zero leaks so far. Hebei Xiu Lin even customized the smooth ports to fit our legacy manifolds—outstanding support."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Linda Park - Maintenance Lead, Precision Automation Inc.

"We’ve been using the Advanced Model since October 2024 across our press lines, and the difference in system stability is undeniable. Before, we’d see pressure spikes that misaligned our stamping tools—now, with the synchronized flow control, those issues are gone. The 230 bar max pressure handles peak loads effortlessly. Maintenance is a breeze too; the corrosion-resistant ductile iron hasn’t degraded despite constant exposure to hydraulic oil and coolant splash. After 8 months, no signs of wear. This is industrial-grade reliability done right."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Marcus Reed - Owner, Reed Fabrication Workshop

"I was skeptical a high-end hydraulic valve would make sense for my smaller shop, but the Base Model has been a solid investment since May 2024. I use it in a custom lift system for vehicle repairs, and the 50 L/min flow rate is more than enough. The cross-shaped design made routing hoses much easier than expected. Only reason I’m not giving 5 stars is the initial setup required some trial and error with alignment—nothing the manual didn’t cover, but took extra time. Now that it’s dialed in, runs flawlessly. For the price, the durability and ISO certification give me peace of mind."Purchase Date: May 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Vasquez - Hydraulic Technician, Offshore Drilling Unit TX-7

"Harsh environment? Saltwater, constant vibration, high-pressure cycles? The Pro Model was worth every penny. We’ve had it running since January 2025 on a critical crane synchronization system—over 5 months non-stop. The -40°C to 120°C temperature tolerance is no joke; it didn’t flinch during a cold North Sea front. We also appreciate the custom epoxy coating Hebei Xiu Lin applied for extra salt corrosion protection. It’s passed all our ISO 10768 compliance checks with flying colors. If you’re in offshore or mining, skip the standard valves—go straight to this."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ David Lin - Production Operations, Apex Auto Systems

"We integrated the Advanced Model into our robotic arm hydraulics in April 2025. After 4 months, uptime has improved by 12%, mainly due to reduced pressure fluctuations. The ±3% flow precision keeps our clamping forces consistent, which directly reduced part rejection rates. Installation was fast—thanks to the BSP thread compatibility—and the team reported no alignment issues. For mid-pressure automotive lines, this is the sweet spot between performance and cost. Customer service also responded within hours when we had a customization query. Highly recommend."Purchase Date: April 2025 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Zhou - Senior Hydraulic Engineer & Consultant

"After reviewing over 50 valve designs in the past decade, the 9006527 series stands out for its precision casting and real-world adaptability. The ductile iron construction with enhanced hardness grading across models allows engineers to match performance to application severity—something most manufacturers don’t offer. Its compliance with ISO 10768 and API 6A standards makes it suitable for everything from factory floors to offshore rigs. For any system requiring true synchronization, this is now my top recommendation."

Rebecca Mills - Industrial Asset Performance Specialist

"In reliability-centered maintenance assessments, the 9006527 consistently scores high on MTBF (Mean Time Between Failures). Field data from multiple clients show 30% fewer hydraulic leaks compared to standard valves, thanks to the threaded port design. The ability to customize port specs and coatings also reduces retrofit costs. For plants aiming to reduce unplanned downtime, this valve delivers measurable ROI—especially in the Pro and Advanced models."

Posted: 2 days ago

"Using the Pro Model in crane hydraulics. The synchronization is flawless. No more jerky movements. Worth the lead time for customization."

Posted: 1 week ago

"Installed in a rock crusher system. Survived 6 months in dusty, high-vibration conditions. No corrosion, no drift. Will be reordering."

Posted: 2 weeks ago

"Performance is excellent, but our custom port modification took 3 extra days. Still, the engineering support was responsive. Happy overall."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.