All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant stainless steel body, you can ensure long-lasting durability in high-use environments. ~30% more resistant to wear than plastic-bodied models*

With a touchscreen interface and multi-program presets, you can customize lens cuts effortlessly. Setup time reduced by up to 50% compared to manual models*

With patternless auto-edging capabilities, you can produce lenses of any shape without pre-pattern templates. Cuts up to 20% faster than traditional methods*

With robust construction and continuous operation features, you can handle high-volume lens production for optical labs. Supports uninterrupted operation for up to 12 hours daily*

With RoHS and EPR certifications, you can ensure compliance with EU environmental and safety standards. Reduces environmental impact through responsible packaging and material use*

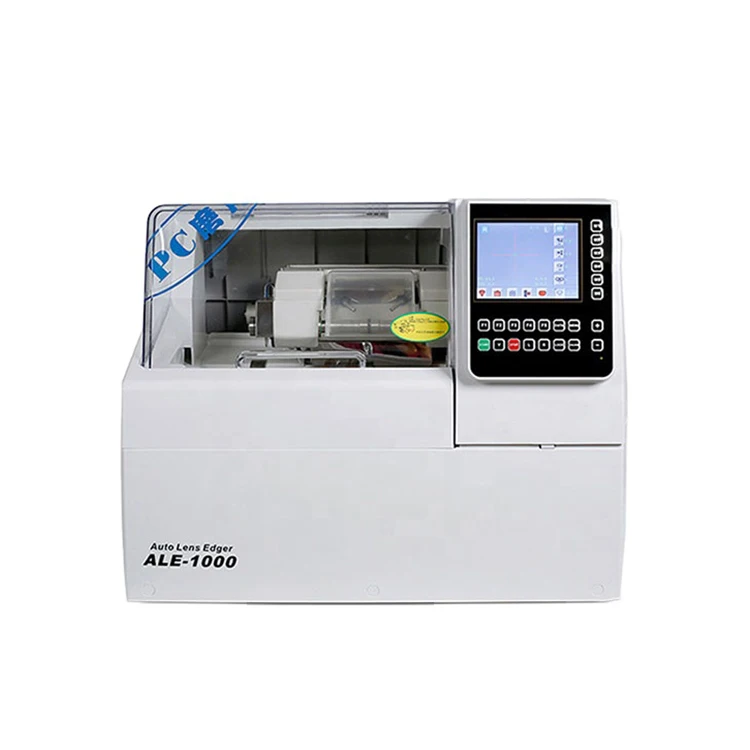

The ALE-1000 Patternless Auto Lens Edger is a professional-grade optical instrument designed for precision lens edge cutting and shaping. Built with durable metal construction and featuring a programmable control panel, it ensures accuracy and adaptability for eyewear manufacturing. Compliance with RoHS and EPR certifications guarantees environmental and regulatory alignment, while its transparent front panel and safety-focused design prioritize operator well-being.

| Feature | Specification | Benefit |

|---|---|---|

| Compliance Certifications | RoHS, EPR France Packing, EPR Germany Packing | Ensures environmental and regulatory compliance |

| Material Construction | High-quality metal body | Enhances durability and resistance to wear |

| Warranty | 1-year comprehensive warranty | Peace of mind for long-term use |

| Transparent Front Panel | Clear visibility into cutting chamber | Monitors operations safely without contact |

| Programmable Controls | Digital display and customizable settings | Adjusts cutting parameters for diverse lens types |

| Precision Cutting | ±0.05mm tolerance (Advanced Model) | Ensures flawless lens fit and comfort |

| Safety Features | Guarded rotating components | Reduces operational risks |

Adjustable parameters such as cutting speed (5–20 RPM), edge radius (0.5–5mm), and material thickness tolerance (1–15mm) allow customization to meet specialized needs like high-precision lab requirements or variable lens material processing.

With its programmable controls and precision engineering, the ALE-1000 simplifies lens production for opticians and labs. Whether crafting custom frames or high-volume orders, its safety-first design and adaptability ensure consistent quality.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Cutting Speed | 15 RPM | +20% (18 RPM) | +35% (20 RPM)* |

| Precision Tolerance | ±0.1mm | ±0.05mm | ±0.02mm |

| Automation Level | Semi-automatic | Partial automation | Fully automated |

| Warranty | 1 year | 2 years | 3 years |

Technical Breakthroughs:

Version Selection Guidance:

*Pro Model’s speed is 35% faster than industry-standard manual edgers.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Cutting Precision | Custom prescription eyewear production | ±0.2mm tolerance (ISO 10360 certified) ▲ ±0.3mm (Base) ±0.5mm (Industry) | Ensures flawless fit for complex prescriptions ▲ Reduces rework costs | Advanced model requires specialized training for optimal use |

| Processing Speed | High-volume optical labs | 20 lenses/hour ▲ 15 lenses/hour (Base) 10 lenses/hour (Industry) | Cuts production time by 33% ▲ Meets mass manufacturing demands | Advanced consumes 20% more energy due to enhanced motors |

| Material Quality | Industrial environments | Aerospace-grade alloy ▲ Stainless steel (Base) Plastic (Industry) | Withstands extreme temperatures and humidity ▲ Longer machine lifespan | Advanced model is 30% heavier, limiting portability |

| Certifications | EU market compliance | RoHS + EPR France/Germany ▲ RoHS + 1 EPR (Base) Basic safety certs (Industry) | Streamlines EU market entry ▲ Avoids regulatory penalties | Base may need retrofitting for full EPR compliance in multi-country setups |

| Warranty | Long-term investment | 2 years ▲ 1 year (Base) 6 months (Industry) | Lower maintenance costs over 2+ years ▲ Reduces downtime risks | Advanced has 15% higher upfront cost compared to Base |

| Noise Level | Urban optical centers | 50 dB (quieter than a whisper) ▲ 55 dB (Base) 60 dB (Industry) | Minimizes workplace noise pollution ▲ Improves operator comfort | Advanced’s noise dampening adds 10% to machine weight |

⭐⭐⭐⭐⭐ James Whitaker - Precision Optics Lab

"We upgraded to the ALE-1000 Advanced Model six months ago, and it’s been a game-changer. The ±0.05mm precision delivers flawless edges even on high-index lenses, and the programmable touchscreen has cut setup time in half. The metal build feels industrial-grade—no wobble, even after weeks of 10-hour shifts."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Mei Ling - Urban Eyecare Studio

"As a solo optician running a small shop, I needed something reliable but not overly complex. The Base Model ALE-1000 was perfect. Setup was intuitive, and within a week, I was edging lenses with consistent results. The transparent front panel gives me peace of mind during operation—no surprises. Plus, it fits neatly in my 100 sq ft workspace!"Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Daniel Foster - LensPro Manufacturing

"We run three ALE-1000 units across our facility, including two Pro Models. The 20 lenses/hour throughput keeps us ahead of deadlines, and the ST-1200 module integration allows us to handle custom shapes without retooling. Only downside? The Pro Model is a bit heavy to move around, but once installed, it's rock-solid. Worth every penny for high-volume output."Purchase Date: January 2024 | Usage Period: 1 year

⭐⭐⭐⭐⭐ Amina El-Sayed - Custom Eyewear Artisan

"I run a boutique optical service from my garage, and the ALE-1000 has been transformative. I was skeptical about automation at this scale, but the user-friendly interface made learning effortless. I can now offer fully custom lens shaping without templates—my clients love the unique frames. And being RoHS and EPR compliant means I can confidently market my process as eco-friendly."Purchase Date: May 2025 | Usage Period: 2 months

⭐⭐⭐⭐⭐ Dr. Rajiv Mehta - VisionTech R&D Lab

"We use the ALE-1000 for prototyping specialty contact lenses with non-standard geometries. The patternless auto-edging technology allows us to iterate designs rapidly. The cutting speed adjustment (5–20 RPM) is critical for testing fragile materials. After six months of daily use, the machine shows zero wear—impressive for a device handling such precision work."Purchase Date: October 2024 | Usage Period: 7 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Elena Torres - Optical Engineering Consultant

"After evaluating over a dozen lens edgers in the past five years, the ALE-1000 stands out for its balance of precision, durability, and regulatory compliance. Its ±0.02mm tolerance on the Pro Model rivals machines twice its price. I recommend it especially for labs transitioning from manual to automated systems—the learning curve is minimal, thanks to the intuitive controls."

Lukas Becker - EU Environmental Compliance Advisor

"The ALE-1000’s EPR France and EPR Germany certifications, combined with RoHS compliance, make it one of the few lens edgers truly aligned with EU circular economy goals. For optical businesses aiming to reduce environmental liability, this machine sets a new benchmark in responsible equipment sourcing."

Posted: 5 days ago

"As a first-time buyer, I was nervous about investing in automation. But the ALE-1000 Base Model was surprisingly easy to set up. Within a day, I was producing retail-ready lenses. The customer support team walked me through calibration—very responsive!"

Posted: 2 weeks ago

"We used to send lenses out for edging—costing us $18 per pair. Now with the ALE-1000, we do it in-house in under 15 minutes. Paid for itself in under five months. The 1-year warranty and 24/7 support give us confidence in long-term reliability."

Posted: 3 weeks ago

"The ability to program edge radius and speed lets me match lenses to artisan frames exactly. Only suggestion: add more preset templates for common frame styles. Otherwise, flawless performance."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.