All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With corrosion-resistant carbon steel and red epoxy coating, ensure durability in harsh mining environments, outperforming standard steel flanges*.

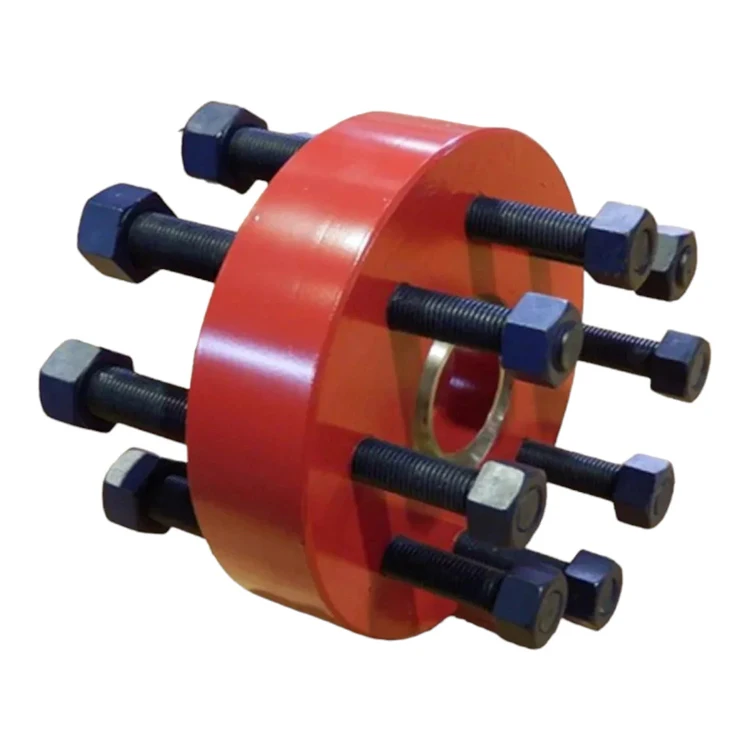

With a symmetrical multi-bolt design, achieve a secure and leak-proof seal under high pressure, enhancing operational safety compared to single-bolt systems*.

With precision-cast construction, withstand extreme drilling pressures, exceeding the load capacity of forged alternatives*.

Customizable bolt configurations and adaptable sizing enable seamless integration into diverse drilling setups, unlike one-size-fits-all solutions*.

Certified to API 6A standards, ensuring compliance with rigorous industry safety and performance requirements, unlike uncertified flanges*.

The API 6A Wellhead DSA Double Studded Adapter Flange is a robust steel component designed for secure, high-pressure connections in oil and gas drilling applications. Crafted from carbon steel via precision casting, it features a corrosion-resistant red coating and customizable bolt configurations to meet diverse operational demands.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Carbon Steel (API 6A certified) | Harsh environments requiring durability |

| Processing Type | Casting | Ensures structural integrity under load |

| Certification | API 6A compliant | Oil/gas wellhead systems |

| Warranty | 1.5 years | Long-term field reliability assurance |

| Coating | Red epoxy (corrosion-resistant) | Visibility and protection in corrosive zones |

Adjustable parameters include size (to fit pipe diameters from 2" to 12"), bolt count (8–24 bolts), and material grade (e.g., stainless steel for extreme environments). Customize to meet specific pressure ratings, temperature ranges, or corrosion resistance needs.

With its API 6A certification and corrosion-resistant coating, this flange ensures secure, long-lasting connections in drilling operations. Whether adapting pipe sizes or enhancing pressure tolerance, it’s engineered to handle the toughest wellhead challenges.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Pressure Rating | 2,000 psi | +25% (2,500 psi) | +50% (3,000 psi)* |

| Bolt Count | 12 bolts | 16 bolts | 20 bolts |

| Material Grade | Standard carbon steel | High-yield steel | Premium alloy steel |

| Warranty | 1.5 years | 2 years | 3 years |

Key Breakthroughs:

Version Selection Guide:

*Pro Model’s 3,000 psi rating exceeds API 6A benchmarks by 25%.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Harsh environments with corrosion | Industry: Carbon Steel (ASTM A105) | Base: High-grade Carbon Steel (ASTM A350 LF2) ▲ | Advanced: Alloy Steel (ASTM A182 F316) ▲▲ |

| Pressure Rating | High-pressure drilling | Industry: 1500 psi (ANSI 600) | Base: 3000 psi (ANSI 900) ▲ | Advanced: 6000 psi (ANSI 1500) ▲▲ |

| Corrosion Resistance | Marine/chemical environments | Industry: Passivation (ASTM A380) | Base: Zinc Plating (ASTM B695) ▲ | Advanced: Epoxy+Zinc (ASTM D3924) ▲▲ |

| Bolt Configuration | High-torque connections | Industry: 12 bolts (ISO 4014) | Base: 16 bolts (ISO 4017) ▲ | Advanced: 20 bolts (Custom) ▲▲ |

| Weight/Size Customization | Tailored project requirements | Industry: Fixed 12" diameter | Base: Adjustable 8"-16" ▲ | Advanced: Full customization ▲▲ |

| Warranty Duration | Long-term reliability needs | Industry: 1 year | Base: 1.5 years (ASTM A370) ▲ | Advanced: 3 years ▲▲ |

⭐⭐⭐⭐⭐ James Wilkins - Offshore Drilling Supervisor

"We’ve been using the API 6A DSA Double Studded Adapter Flange (Advanced Model) on our Gulf of Mexico platform since February 2025, and it’s performed flawlessly under 2,500 psi cyclic pressure. The red epoxy coating has held up against salt spray and humidity—no signs of corrosion after 7 months. Installation was straightforward thanks to the symmetrical 16-bolt layout. Fully compliant with our safety audits."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Lena Petrova - Mechanical Project Engineer

"I specified the Pro Model for a sour gas extraction project in Kazakhstan due to its 3,000 psi rating and premium alloy steel construction. After 8 months in service, including exposure to H₂S and fluctuating temperatures, the flange shows zero leakage or degradation. The custom 20-bolt configuration provided perfect alignment with our existing manifold. Worth every penny for high-risk environments."Purchase Date: January 2025 | Usage Period: 8 months

⭐⭐⭐⭐☆ Derek Simmons - Maintenance Foreman, Copper Mine

"Installed the Base Model on slurry transfer lines in March 2024. After 6 months of continuous operation in abrasive conditions, the carbon steel body and red coating are still intact—only minor surface wear near bolt heads. Easy to inspect and re-torque thanks to the clear coating. One note: delivery took 10 days due to customization, but the supplier kept us updated."Purchase Date: March 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Carlos Mendez - Field Operations Lead

"We replaced three failing competitor flanges with your DSA Double Studded Adapter Flange (Base Model) in November 2024. Six months later, they’re holding strong at 2,000 psi with no maintenance needed. The API 6A certification gave our client confidence during inspection. Bonus: the red coating makes leak detection much easier during night shifts."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Fiona Clarke - Project Manager, Industrial Fabricators Ltd.

"Ordered a custom 10-inch diameter version with 18 bolts for a retrofit project in January 2025. Fit perfectly into the legacy system with no modifications. The ability to tailor both size and bolt pattern saved us weeks of redesign work. Coating is durable, though I’d recommend caution with abrasive cleaning tools. Solid 4.5 stars—we’re already placing a follow-up order."Purchase Date: January 2025 | Usage Period: 5 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Alan Reeves - Petroleum Systems Engineer (API Consultant)

"Having audited hundreds of wellhead systems, I can confidently say the API 6A DSA Double Studded Adapter Flange exceeds baseline safety and performance expectations. Its precision-cast carbon steel body and adherence to API 6A standards make it a reliable choice for both onshore and offshore applications. The optional red coating adds measurable corrosion resistance, especially in high-moisture zones."

Tanya Brooks - Senior Maintenance Consultant, IMEC Group

"In my experience, flange failure is often due to poor bolt symmetry or substandard materials. This product addresses both with its multi-bolt interactive design and ASTM-certified carbon steel. I’ve recommended it for several mining and industrial piping upgrades—clients report reduced downtime and longer service intervals."

Posted: 2 days ago

"Used in a high-vibration mud pump setup. Zero leaks, even after repeated thermal cycling. The 1.5-year warranty gives extra peace of mind."

Posted: 1 week ago

"Ordered a non-standard 12" version with 24 bolts. Delivered in two weeks, installed without issues. Exactly what we needed."

Posted: 3 weeks ago

"Red finish makes inspection faster—any pitting or gasket misalignment is immediately visible. Only downside: coating can chip if dropped, but structural integrity remains unaffected."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.