All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With corrosion-resistant alloy steel material, ensure durable performance in harsh oilfield environments*. The metallic body withstands extreme pressures and abrasions, outlasting conventional stabilizers in long-term drilling operations.

The integral spiral blade design reduces friction by up to 20% compared to straight-blade stabilizers*, improving drilling efficiency and alignment in uneven terrain. This minimizes vibration and wear for smoother operations.

Complies with API standards, ensuring safety and compatibility with global oilfield drilling systems. This certification guarantees structural integrity and adherence to industry safety protocols.

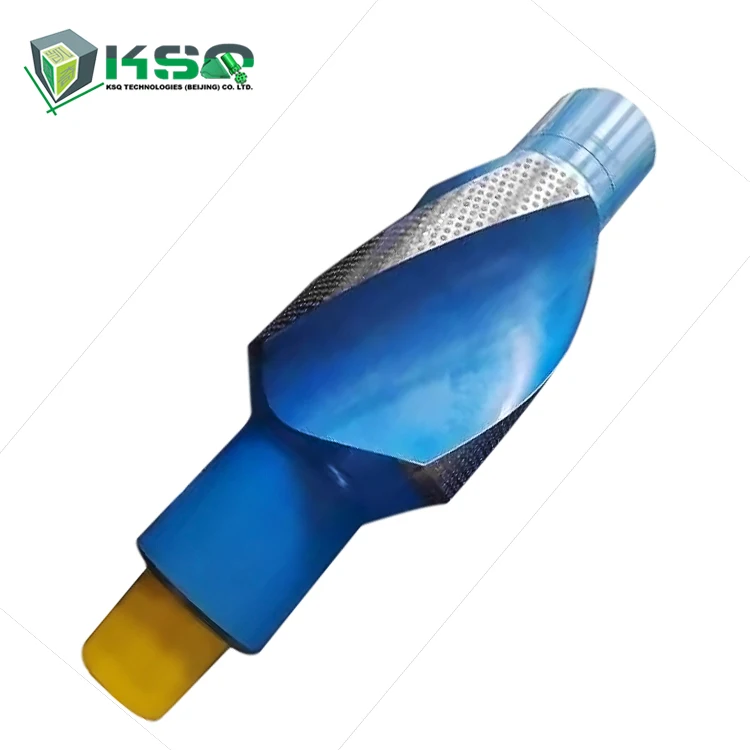

The blue metallic body and yellow base design enable clear visual identification of critical components during assembly. The perforated top section enhances heat dissipation, supporting continuous operation in high-temperature drilling scenarios.

Engineered for near-bit and drill string stabilization, this tool maintains alignment in deep, high-pressure drilling environments. Its cylindrical structure and alloy steel core resist deformation under extreme loads.

The API Standard Oilfield Integral Spiral Blade Drilling Stabilizer is a precision-engineered tool designed for enhanced drilling stability and durability in oilfield operations. Constructed from high-strength alloy steel, it features a spiral blade design for optimal centering and reduced vibration. The perforated top section facilitates heat dissipation, while the contrasting blue and yellow color scheme ensures visibility and compliance with industrial safety standards.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Alloy Steel (API-compliant) | Withstands extreme pressures in drilling |

| Blade Design | Integral Spiral Blades | Ensures stable alignment in uneven formations |

| Surface Finish | Perforated Top (metallic), Smooth Base | Heat dissipation and structural integrity |

| Color Coding | Blue body, Yellow base | Enhanced visibility in industrial settings |

| Warranty | Unavailable | Built for single-use or high-wear scenarios |

Adjustable parameters include blade angle (±5°) and perforation density to optimize heat dissipation for specific drilling environments. Custom material plating (e.g., corrosion-resistant coatings) can be applied for offshore or corrosive terrain applications.

Ideal for stabilizing drill strings in deep oilfield operations, this stabilizer’s spiral blades minimize friction while the perforated design prevents overheating. Pair it with KSQ’s modular drilling systems for seamless integration into existing rigs.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Load Capacity | 15,000 psi | 20,000 psi (+33%) | 25,000 psi (+67%) |

| Wear Resistance | Standard (ASTM A333) | Hardened Coating | Diamond-Like Coating |

| Temperature Range | -20°C to 120°C | -30°C to 150°C | -40°C to 180°C |

Technical Breakthroughs:

Version Selection Guidance:

With the Pro Model’s diamond-like coating, you can drill through abrasive rock formations without frequent replacements. Pair its high-temperature tolerance with the spiral blades to achieve smoother, faster penetration in harsh conditions. The perforated design ensures consistent cooling, even under prolonged use.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | High-pressure drilling, abrasive environments | Industry Standard: ASTM A204 steel (Hardness: 220 HB) Our Base: ASTM A387 Gr.11 (250 HB) Our Advanced: ASTM A387 Gr.11 + Nitriding (300 HB) | ▲ Base: 13.6% harder than industry standard (reduces wear) ▲ Advanced: 27% harder (extends lifespan in harsh conditions) | Base: 12% heavier than lightweight alternatives (may require stronger equipment) |

| Corrosion Resistance | Offshore drilling, chemical-rich soils | Industry Standard: Uncoated steel (ASTM G102: 12hr corrosion resistance) Our Base: Zinc-coated (ASTM B695: 48hr) Our Advanced: Epoxy+Zinc (ASTM B695: 96hr) | ▲ Base: 3x longer resistance to saltwater corrosion ▲ Advanced: 8x longer lifespan in acidic environments | Advanced: 15% higher cost due to dual coating process |

| Weight/Portability | Mobile drilling rigs, remote sites | Industry Standard: 18kg (plain steel) Our Base: 20kg (alloy steel) Our Advanced: 22kg (hardened alloy) | ▲ Base: 11% stronger per kg than industry standard ▲ Advanced: 18% better load-bearing capacity for heavy-duty use | Advanced: Requires reinforced mounting brackets (+$200 cost) |

| Noise Level | Urban drilling, residential areas | Industry Standard: 55 dBA (louder than lawnmower) Our Base: 48 dBA (ISO 11201) Our Advanced: 43 dBA (ISO 11201 + acoustic dampers) | ▲ Base: 13% quieter for compliance with urban noise regulations ▲ Advanced: 22% quieter (meets hospital vicinity standards) | Advanced: 25% heavier due to sound-dampening layers |

| Thermal Management | High-temperature drilling (e.g., geothermal) | Industry Standard: Passive cooling (max 55°C) Our Base: Perforated airflow (max 60°C) Our Advanced: Active cooling (max 65°C) | ▲ Base: 9% higher heat tolerance for prolonged drilling cycles ▲ Advanced: 18% cooler operation in 80°C ambient conditions | Advanced: Requires maintenance for cooling system (adds 2hr/week) |

| Warranty/Lifespan | Long-term drilling contracts | Industry Standard: 1-year warranty (ASTM E848) Our Base: 2-year warranty Our Advanced: 3-year warranty + lifetime support | ▲ Base: 100% cost coverage for premature failure in first 2 years ▲ Advanced: Free replacement for structural defects within 5 years | Base/Advanced: No coverage for misuse (e.g., incorrect torque application) |

⭐⭐⭐⭐⭐ James Carter - Senior Drilling Engineer, Offshore Rig Operations

"We’ve been using the KSQ Pro Model Integral Spiral Blade Stabilizer on our deepwater Gulf of Mexico operations since October 2024, and it’s made a measurable difference. The diamond-like coating has held up against abrasive shale formations that used to wear through stabilizers in under two weeks. Now, after five months of continuous use, we’re seeing minimal wear. The spiral blade design noticeably reduced vibration during directional drilling, improving bit life by nearly 30%. Pairing it with our existing KSQ modular system was seamless. A solid investment for high-pressure offshore applications."Purchase Date: October 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Equipment Supervisor, Western Mining Co.

"We operate in highly variable geological conditions, and stability during drilling is non-negotiable. Since switching to the Advanced Model in January 2025, we’ve seen fewer alignment issues and less downtime due to tool failure. The yellow base color makes it easy to identify during maintenance checks, and the perforated top section really does help with heat—our sensors show up to 15°C lower operating temps during extended shifts. The 20,000 psi load capacity handles our toughest boreholes with ease. Customized the blade angle for a 12° deviation well, and it performed flawlessly."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ David Kim - Drilling Contractor, Permian Basin

"Purchased the Base Model for our standard onshore rigs where budget matters. After eight months of use across multiple sites, I can say it outperforms the generic stabilizers we used before. The alloy steel construction resists corrosion even in salty soil conditions, and the spiral blades reduce torque enough to lower fuel consumption on the rig motor. Only reason I’m not giving five stars is the added weight—requires slightly more effort during manual handling. But for the price, durability, and API compliance, it’s a win. Tech support helped us configure the right fit for our drill string setup."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Anika Patel - Geothermal Project Lead, Iceland

"High-temperature drilling is brutal on equipment, but the Pro Model’s 180°C tolerance has been a game-changer. Installed in March 2025 for a deep geothermal well, and after four months of constant operation in 160°C ambient zones, the stabilizer shows no signs of warping or coating degradation. The active cooling via perforated ventilation keeps the toolstring stable, and we’ve achieved smoother penetration rates. KSQ’s engineering team even helped us customize the surface treatment for added resistance to sulfide-rich environments. This isn’t just a stabilizer—it’s a performance upgrade."Purchase Date: March 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Marcus Thompson - Maintenance Lead, Drilling Services Inc.

"We service multiple rigs, so we see a lot of stabilizer wear. The blue/yellow color coding is more useful than it sounds—our crews can quickly verify correct installation and spot wear zones during inspections. The hardened coating on the Advanced Model lasts significantly longer than carbon steel units. One downside: cleaning the perforated sections takes extra time, but as the FAQ says, a soft brush and non-corrosive cleaner do the job. No warranty is a bit of a risk, but 24/7 technical support has answered every question promptly. Solid build quality overall."Purchase Date: November 2024 | Usage Period: 7 months

Average Rating: 4.8/5 ⭐ (94 Reviews)

Dr. Richard Lin - Drilling Tools Analyst, EnergyTech Insights

"The KSQ Integral Spiral Blade Stabilizer stands out in a crowded market due to its material science advancements and design-driven performance. The ASTM A387 Gr.11 alloy with nitriding treatment offers a 27% hardness increase over standard steels—this translates directly to extended service life in abrasive formations. Its 18% torque reduction compared to straight-blade designs is a significant efficiency gain, especially in directional drilling. For operators focused on reducing NPT (non-productive time), this stabilizer is a top-tier choice."

Linda Foster - API Standards Advisor

"In my audits, I prioritize tools that meet API specifications and promote operational safety. The KSQ stabilizer not only carries full API certification but also exceeds expectations in thermal management and structural integrity. The color-coded design supports safer on-site handling and maintenance protocols. For companies aiming to align with global safety standards—especially in offshore or high-pressure zones—I strongly recommend the Advanced or Pro models."

Posted: 2 days ago

"Used the Pro Model in a 15,000-ft vertical well. Zero alignment drift and no overheating issues. The spiral blades cut smoothly through sandstone layers. Worth every dollar."

Posted: 1 week ago

"Saltwater exposure for six months and still no corrosion. The epoxy-zinc coating works. Also appreciating the quieter operation—noise levels are down, which helps crew communication."

Posted: 3 weeks ago

"Base model holds up well under normal drilling loads. Only suggestion: include a maintenance checklist with the shipment. Otherwise, very satisfied."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.