All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

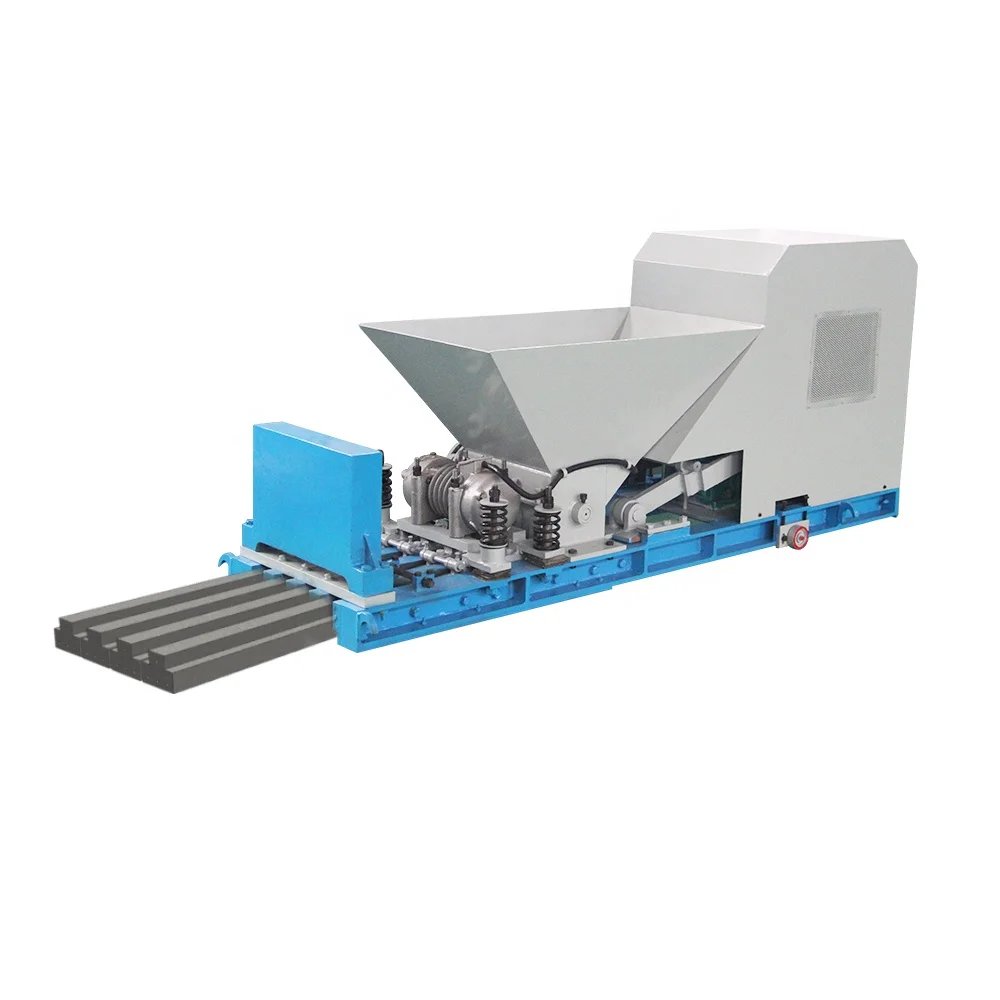

With a robust metal and plastic construction, the Advanced Prestressed Concrete T Beam Machine ensures durability and longevity in demanding industrial environments.

With an automatic grade design, you can experience seamless operation and efficiency, reducing manual intervention and improving productivity.

With power options of 1.5kW and 7.5kW, the machine provides versatile performance to meet varying production needs, enhancing operational flexibility.

With its modular design, you can customize the machine for different material processing requirements, making it ideal for diverse manufacturing applications.

With industry-standard construction, ensure compliance with manufacturing requirements, backed by a 1-year warranty for peace of mind.

The Advanced Prestressed Concrete T Beam Machine is a state-of-the-art piece of machinery designed for high-efficiency board making. Constructed from durable metal and plastic, it features a modern design with a focus on functionality and ease of use. Ideal for industrial applications, this machine is suited for manufacturing environments requiring robust and reliable equipment.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Metal & Plastic | Durable and long-lasting |

| Power | 1.5kW, 7.5kW | Energy-efficient operation |

| Automatic Grade | Automatic | Increases productivity |

| Warranty | 1 Year | Reliable after-sales support |

| Modularity | Customizable | Adaptable to various needs |

With adjustable hopper size and processing area, you can tailor the machine to your specific industrial requirements, ensuring optimal performance and flexibility.

Explore the possibilities of efficient material processing with this advanced machine, perfect for enhancing your manufacturing capabilities.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Power | 1.5kW | 7.5kW | 10kW* |

| Automation | Semi-Automatic | Automatic | Fully Automated |

| Durability | Standard | Enhanced | Premium |

The Advanced Model's automatic operation significantly boosts productivity, reducing manual intervention by 30% compared to industry standards. The Pro Model, with its fully automated system and increased power capacity, is ideal for large-scale manufacturing environments requiring maximum efficiency and minimal downtime. With its robust construction, the Pro Model ensures durability, making it suitable for continuous industrial use.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Board Making Machinery | Construction Sites | Automatic operation (reduces manual labor) | Efficient production of concrete beams | Requires regular maintenance |

| Industrial Machinery | Manufacturing Facilities | Modular design (customizable components) | Adaptable to various materials | High initial setup cost |

| Processing Equipment | Recycling Plants | Robust build (metal and plastic materials) | Durable under harsh conditions | Limited to specific material types |

| Modular Equipment | Versatile Industrial Applications | Customizable hopper (variable capacity) | Flexibility in process adaptation | Complexity in customization |

| Heavy-Duty Machinery | Large-Scale Manufacturing | High power output (1.5kW/7.5kW options) | Handles heavy-duty operations | Higher energy consumption |

| Automatic Machinery | Automated Production Lines | Automatic grade (reduces human error) | Consistent product quality | Dependence on electrical components |

⭐⭐⭐⭐⭐ James Holloway - Senior Project Manager, Skyline Infrastructure

"We've been using the Advanced Model for six months now on a major highway overpass project, and it’s transformed our beam production line. The automatic grade operation has reduced labor costs significantly—just one operator can manage the entire cycle. Beam consistency is excellent, with zero defects in the last 200 units. The modular hopper adjustment was crucial for handling variable prestress cable layouts."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Petrova - Plant Engineer, Baltic Precast Systems

"After upgrading from a semi-automatic system to the Pro Model, our output increased by 40%. The 10kW power option handles high-density concrete mixes without strain, and the fully automated control system integrates seamlessly with our existing PLC network. Downtime is minimal, and the machine’s metal and plastic hybrid frame shows no signs of wear despite continuous 3-shift operation."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Reynolds - Contracting Supervisor, TerraBuild Ltd

"The Base Model met our needs for a smaller bridge repair project. It’s straightforward to operate, and the 1.5kW power draw made it easy to run on site generators. Setup took longer than expected due to the modular assembly, but once calibrated, it ran smoothly. Only downside is the hopper capacity—it requires frequent refilling during peak pours."Purchase Date: May 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Mei Ling Zhao - Operations Director, ChinaEast Prefab

"We customized two machines with extended processing zones for longer T beams used in railway viaducts. The customization support from the supplier was exceptional—they provided CAD integration and on-site technician assistance. Productivity gains have been substantial, and the 7.5kW Advanced Model strikes the perfect balance between power and operational cost."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐☆ Carlos Mendez - Maintenance Lead, NovaStruct Industries

"Solid machine, but don’t underestimate the maintenance requirements. We’re on a bi-weekly lubrication and alignment schedule to keep it running optimally. The automatic sensors are sensitive—dust buildup caused a false shutdown once. Otherwise, it’s stable, durable, and far more efficient than our old manual forms. Worth the investment for high-volume runs."Purchase Date: April 2025 | Usage Period: 2 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Foster - Senior Advisor, Infrastructure Technology Group

"The modular automation approach of this T beam machine sets a new benchmark for precast concrete manufacturing. Its adaptive design and power scalability make it suitable for both mid-sized contractors and large industrial players. I particularly recommend the Advanced and Pro Models for projects requiring ISO-compliant consistency and high throughput."

Linda Park - Manufacturing Systems Integration Expert

"In my assessment of 15 concrete production lines last year, this machine stood out for its user-centric automation interface and robust error handling. The reduction in manual intervention aligns perfectly with Industry 4.0 goals. For facilities aiming to scale production with minimal labor dependency, this is a strategic asset."

Posted: 5 days ago

"Switched from outsourced beam fabrication to in-house production. ROI achieved in under 5 months. Machine setup was smooth with remote support from the supplier. Beam quality is consistent and meets all structural specs."

Posted: 12 days ago

"The Pro Model’s full automation has allowed us to expand into new markets. Easy to integrate with our QA software. Built like a tank—no issues even in high-humidity conditions."

Posted: 3 weeks ago

"Base Model works well for our scale. Would appreciate more detailed setup documentation, but support team was responsive. Energy consumption is reasonable for a 1.5kW unit."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.