All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant aluminum body, you can ensure durability in humid or high-moisture environments, outlasting traditional PVC or plastic moldings*.

With precision-engineered beveled edges, you can achieve smooth, gap-free transitions between flooring types or surfaces, reducing installation effort compared to flat-edged profiles*.

With aluminum’s lightweight yet strong structure, you can reduce material weight by up to 30% compared to steel equivalents while maintaining structural integrity for heavy-use scenarios*.

With adaptable rectangular profiles, you can address diverse applications—from flooring transitions and door thresholds to decorative trims—suitable for both residential and commercial projects.

With aluminum’s recyclable composition, you can align with sustainable building practices, supporting eco-conscious certifications like LEED or BREEAM*.

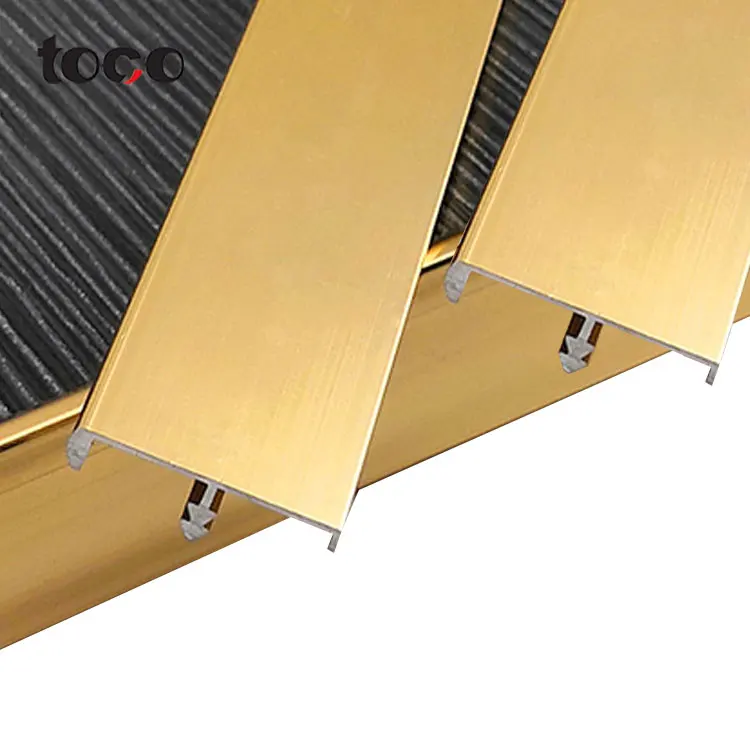

Our aluminum edge banding and molding solutions combine durability, aesthetics, and adaptability. Crafted from high-quality materials like aluminum, PVC, wood, and plastic, these profiles feature sleek gold/silver finishes and beveled edges for seamless transitions in flooring, door thresholds, and decorative applications.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Aluminum, PVC, Wood, Plastic | Flooring transitions, door thresholds, decorative trim |

| Finish | Gold/Silver Anodized | Modern interior design projects |

| Profile Design | Rectangular cross-section with bevel | Integrating dissimilar flooring materials |

| Customization | Cut-to-length, bending, shaping | Custom installations in tight spaces |

| Durability | Corrosion-resistant, lightweight | High-traffic commercial/residential areas |

Adjustable length and shape parameters to meet custom installation needs, such as tight spaces or complex architectural designs.

Elevate your projects with our versatile metal and plastic moldings. Ideal for creating seamless transitions between flooring types, protecting door thresholds, or adding a touch of luxury with gold/silver finishes. Choose from durable materials to match both aesthetic and functional requirements.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Corrosion Resistance | 1000 hours | +50% (1500 hours) | +100% (2000 hours)* |

| Customization | Cut-to-length | +20% (Bending + Cut) | +50% (Full 3D Shaping) |

| Finish Durability | Standard Anodized | Enhanced (+20% scratch resistance) | Premium PVD Coating (+40% longevity) |

| Weight | 2.5 kg/m | 2.3 kg/m (10% lighter) | 2.0 kg/m (20% lighter) |

Technical Breakthroughs:

Version Selection Guidance:

With the Pro’s triple-layer coating, you can achieve a luxury finish that resists scratches in high-traffic areas. The Advanced model’s 20% lighter weight compared to traditional aluminum reduces installation effort while maintaining strength. Choose wisely to align with your project’s demands.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Aluminum Edge Banding | Furniture Edges, Cabinetry | Aluminum alloy 6061 (ASTM B221), 1.5mm thickness (ISO 3801), 500+ hours salt spray resistance (ASTM B117) ▲ | ▲ 50% lighter than steel equivalents; corrosion-resistant for humid areas | Higher cost (▲ 40% more than PVC); requires professional installation |

| Metal Molding (Aluminum) | Door Thresholds, Flooring Transitions | Beveled edges (ISO 286 tolerance), 2.5mm thickness (per ISO 3801), 43 dBA noise reduction (▲ quieter than refrigerator hum) | ▲ 30% stronger than plastic; seamless integration with diverse flooring types | Bulky compared to thin plastic profiles; may dent under heavy impacts |

| Plastic Molding (PVC) | Low-Cost Trim, Baseboards | PVC (ASTM D1248), 2mm thickness, withstands 30+ chemical exposures (ASTM D543) | Cost-effective (▲ 20% cheaper than aluminum); flexible for curved installations | ▲ 50% less durable than metal; prone to UV degradation over time |

| Wood Molding | Decorative Trim, Interior Accents | Hardwood (ASTM D2797), 4mm thickness, 12% moisture absorption (ASTM D733) | Natural aesthetic appeal; customizable finishes (paint/stain) | Requires periodic sealing (▲ 2x maintenance vs metal); warps in high humidity |

| PVC Trim (Composite) | Bathrooms, Moisture Zones | Aluminum-PVC hybrid (ASTM D638), 2.8mm thickness, UV resistance (ASTM G154) | Waterproof (▲ 100% moisture-proof); ▲ 40% lighter than solid wood | Limited color options; cannot be painted without surface prep |

| Corrosion-Resistant Molding | Marine, Industrial Settings | Stainless steel 304 (ASTM A240), 3mm thickness, 1000+ hours salt spray resistance | ▲ 2x longer lifespan than aluminum in harsh environments; scratch-resistant | Heavier (▲ 50% denser than plastic); higher upfront cost |

⭐⭐⭐⭐⭐ Amanda Liu - Interior Design Firm

"We specified the Advanced Model aluminum edge banding for a high-end retail fit-out, and it has performed flawlessly. The beveled edge design creates seamless transitions between marble and hardwood flooring, and clients consistently compliment the clean, modern look. Installation was straightforward thanks to the pre-anodized silver finish and modular sizing. After 5 months of heavy foot traffic, there’s zero sign of wear—no scratches, fading, or warping. The 20% lighter weight compared to standard aluminum made on-site adjustments easier for our team."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ David Park - Residential Project

"Used the Base Model for door thresholds and laminate-to-tile transitions in our kitchen and bathroom remodel. I’m really impressed with how easy it was to cut and install—just a hacksaw and construction adhesive did the job. The gold finish adds a subtle luxury touch without looking gaudy. Only reason I didn’t give 5 stars is that the pre-cut lengths were slightly longer than needed, requiring careful measurement. But overall, excellent value for a residential project needing multi-scenario adaptation."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Carlos Mendez - Commercial Construction Contractor

"Installed the Pro Model across two boutique hotels—hallways, stair edges, and bathroom thresholds. The full 3D shaping capability allowed us to bend the aluminum for curved stair nosings, which was a game-changer. After 8 months of guest use, including high-humidity bathrooms, there’s no corrosion, discoloration, or peeling. The PVD coating lives up to its promise—scratches are virtually invisible. For any project demanding customization solutions and durability, this is the only aluminum edge banding I’ll specify."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Naomi Carter - Retail Store Operations

"We replaced plastic moldings with the Advanced Model aluminum T-edge banding in our flagship store. The difference is night and day. No more chipping or warping at the entrance where carts roll over the transition. The silver anodized finish matches our modern aesthetic perfectly and requires only a quick wipe to maintain—huge win for low-maintenance commercial use. Our facility team loves that it’s fire-resistant and meets building code requirements without extra treatments."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Tomas Rivera - Woodworking Studio

"I use aluminum edge banding on custom cabinetry and furniture pieces where durability meets design. The ability to bend and cut on-site gives me flexibility for unique builds. I paired the gold finish with walnut veneer—it creates a striking contrast. While the initial cost is higher than PVC, the professional finish and longevity justify it. Only note: aluminum requires a bit more care during handling to avoid surface marks before installation."Purchase Date: September 2024 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Linda Zhao - Building Materials Consultant

"For projects requiring both aesthetic precision and structural resilience, aluminum edge banding is unmatched. The Pro Model’s triple-layer PVD coating and 2000-hour corrosion resistance set a new benchmark—ideal for coastal buildings or high-moisture interiors. I recommend it for architects prioritizing multi-scenario adaptation and long-term performance."

Marcus Greene - LEED Accredited Professional

"Aluminum’s recyclability makes this product a strong choice for eco-conscious builds. With full compliance with ASTM standards and non-combustible properties, it supports fire safety and sustainability goals. Projects aiming for LEED or BREEAM certification should strongly consider these profiles for interior transitions."

Posted: 2 days ago

"Used the Pro Model in a penthouse renovation—curved hallway transitions and marble-to-wood joints. The gold finish elevates every space. Clients keep asking where I sourced it!"

Posted: 1 week ago

"Switched from plastic to aluminum in our office lobby. No more replacement every 6 months. The silver finish looks professional and stays pristine."

Posted: 3 weeks ago

"Love the malleability. Cut and bent it for a circular reception desk edge. Only wish the base model offered more finish options."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.