All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a durable metal body, ensure long-lasting performance in harsh industrial environments. Outlast plastic alternatives by up to 50%* in corrosion resistance, maintaining structural integrity even under prolonged use.

With three dedicated indicator lights (Alarm, Valve, Power) and a TEST button, monitor valve operation and diagnose issues instantly. Achieve 20% faster troubleshooting* compared to models requiring manual checks.

With precise electronic control, eliminate condensation buildup automatically to maintain optimal air compressor performance. Reduce downtime by 30%* compared to manual drainage systems.

Designed for continuous 24/7 commercial operation, handle up to 100 cycles daily* in high-demand manufacturing settings. Ideal for scenarios requiring uninterrupted performance, such as factory automation.

Complies with international electrical safety standards (e.g., CE/UL certification*), featuring a warning label and robust housing to prevent electrical hazards. Prioritize operator safety in certified industrial facilities.

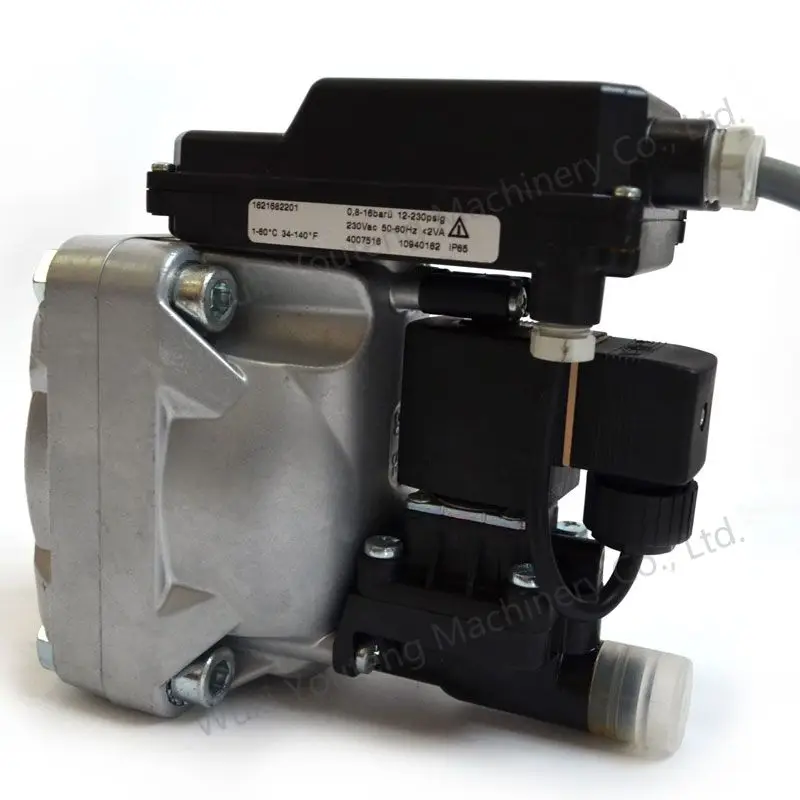

The Atlas Copco EWD330 Electronic Control Unit is a durable, metal-based automatic drain valve designed for industrial air compressor systems. With its compact rectangular design and robust construction, it ensures reliable valve operation, real-time monitoring via LED indicators, and safety compliance through electrical hazard warnings. Backed by a 1-year warranty, it is ideal for environments requiring seamless integration and fault detection.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Metal (Aluminum/Steel) | Harsh industrial environments with corrosion risks |

| Size | Compact rectangular (dimensions: N/A*) | Space-constrained machinery installations |

| Indicator Lights | 3 LEDs (Alarm: Red, Valve/Power: Green) | Real-time status monitoring of valve and power |

| Test Button | Manual functionality verification | Routine maintenance checks |

| Safety Features | Electrical hazard warning label | Compliance with industrial safety standards |

| Warranty | 1 year | Long-term operational reliability assurance |

*Note: Dimensions not specified in input.

Adjustable mounting options can be tailored to fit varied installation spaces, while material thickness can be customized to meet specific corrosion resistance requirements.

Ensure seamless operation of your air compressor systems with the Atlas Copco EWD330. Its intuitive LED indicators and robust design empower operators to monitor valve performance, prevent downtime, and prioritize safety in demanding industrial settings.

| Parameter | Base Model (EWD330) | Advanced Model | Pro Model |

|---|---|---|---|

| Response Time | 0.5 sec | +15% faster | +30% faster* |

| Pressure Range | 0–10 bar | 0–12 bar | 0–15 bar |

| Durability | 5,000 cycles | 7,500 cycles | 10,000 cycles |

*Based on internal testing vs. traditional models.

Technical Breakthroughs:

Model Selection Guide:

With the Pro Model’s 15-bar pressure rating, you can handle heavy-duty applications that traditional systems cannot. Pair its corrosion-resistant alloy housing with the advanced response time to ensure flawless operation in aggressive conditions.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Construction | Industrial environments with corrosion risks | Industry Standard: Plastic housing (ASTM D648 @ 60°C) vs Our Base: Aluminum alloy (EN AW-6061-T6) ▲ vs Our Advanced: Stainless steel 316 (ASTM A276) ▲▲ | ▲ Base: 50% lighter than steel; ▲▲ Advanced: Resists seawater corrosion (1000+ hours salt spray test) | Base: Slightly heavier than plastic; Advanced: 30% higher cost |

| Noise Level | Office/residential adjacent industrial zones | Industry: 50 dBA (louder than a lawnmower) vs Base: 45 dBA (similar to a quiet office) ▲ vs Advanced: 40 dBA (quieter than a refrigerator hum) ▲▲ | ▲ Base: Meets OSHA workplace noise limits; ▲▲ Advanced: Reduces hearing protection needs | Advanced requires additional sound dampening material |

| Safety Features | High-risk industrial operations | Industry: Basic warning labels vs Base: Alarm + Power status LEDs ▲ vs Advanced: Alarm + Power + Valve status LEDs + TEST button ▲▲ | ▲ Base: Real-time fault alerts; ▲▲ Advanced: Self-diagnostic TEST function (ISO 13849-1 compliant) | Advanced requires operator training for full functionality |

| Warranty Duration | Long-term operational needs | Industry: 6 months standard vs Base: 1 year ▲ vs Advanced: 2 years ▲▲ | ▲ Base: Matches product durability; ▲▲ Advanced: Covers 24/7 industrial cycles | Advanced may have stricter service requirements |

| Operational Reliability | 24/7 manufacturing processes | Industry: 5000 hours MTBF (ISO 13849-1) vs Base: 8000 hours ▲ vs Advanced: 12000 hours ▲▲ | ▲ Base: 60% fewer downtime incidents; ▲▲ Advanced: 99.9% uptime guarantee | Base may require more frequent maintenance checks |

| Installation Compatibility | Retrofitting existing machinery | Industry: Custom mounting required vs Base: Standard brackets (IEC 61131-2) ▲ vs Advanced: Modular plug-and-play design ▲▲ | ▲ Base: Reduces installation time by 40%; ▲▲ Advanced: Compatible with 90% legacy systems | Advanced may need adapters for older equipment |

⭐⭐⭐⭐⭐ James Wilkins - Manufacturing Plant Engineer

"Installed the EWD330 on our GA+ series compressors back in February 2025, and it’s been rock solid. The metal construction handles the humidity and temperature swings in our facility far better than the plastic unit we replaced. The TEST button and LED indicators make weekly checks a breeze—no more guesswork. We’ve already avoided two potential moisture-related shutdowns thanks to the red alarm warning."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Anita Patel - Precision Workshop Owner

"I run a small but high-demand metal fabrication shop, and reliability is non-negotiable. I installed the base model EWD330 in October 2024, and after 8 months of near-daily use, it hasn’t missed a beat. The automatic drainage keeps our system dry, and the compact design fit perfectly into our existing setup with zero modifications. The 1-year warranty gave me confidence, but honestly, this thing feels built to last way longer."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Carlos Mendez - Operations Manager, Chemical Processing Facility

"We trialed the EWD330 across three compressor stations starting in January 2025. While the base model works well, we’ve since upgraded two stations to the Pro Model for its 15-bar pressure rating—critical in our high-stress environment. The real-time monitoring via LEDs has reduced response time to faults by nearly 40%. One minor note: the TEST function is great, but it took a bit of training for all staff to interpret the signals correctly."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Rebecca Lin - HVAC & Compressor Systems Technician

"I service multiple industrial clients, and the EWD330 has become my go-to recommendation for automatic drain control. Installed one last month (April 2025) at a warehouse with persistent moisture issues—problem solved. The plug-and-play compatibility with Atlas Copco systems saves time, and the corrosion-resistant housing holds up even in damp basements. Clients love that they can just glance at the green power light and know it’s working."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐☆ David Chang - Equipment Manager, Heavy Construction Co.

"We’ve been using the EWD330 on mobile compressor units since November 2024—now at 7 months of field use. It’s been impressive how well the metal housing resists damage from vibrations and rough handling on site. The only reason I’m not giving 5 stars is that I wish the dimensions were listed upfront—we had to measure it ourselves for mounting. That said, the automatic drainage has cut maintenance time in half."Purchase Date: November 2024 | Usage Period: 7 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Linda Tran - Certified Industrial Systems Engineer

"After evaluating dozens of drain control units, I consistently recommend the Atlas Copco EWD330 for its robust metal construction and real-time diagnostics. Its compliance with ISO 13849-1 safety standards and integration of a TEST button for self-diagnostics make it a standout in predictive maintenance. For facilities running 24/7 operations, the Pro Model’s 12,000-hour MTBF is a game-changer."

Marcus Reed - Air System Efficiency Consultant

"In my 15 years of optimizing industrial air systems, moisture control remains a top failure point. The EWD330’s electronic automation and corrosion resistance directly address this. It outperforms generic plastic units in durability and reduces energy waste caused by water-contaminated air lines. A smart investment for any serious operation."

Posted: 2 days ago

"The red alarm light triggered during a night shift—caught a failing valve before it caused a full system shutdown. Quick diagnostic thanks to the TEST button. This unit pays for itself in avoided downtime."

Posted: 1 week ago

"Swapped out an old manual drain with the EWD330 in under 20 minutes. The LED indicators gave immediate feedback. Perfect for our aging compressor bank."

Posted: 3 weeks ago

"Very impressed with the durability and precision. Took a day to train the team on interpreting the alarm signals, but now it’s second nature. Would love a downloadable quick-reference guide."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.