All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant metal spindles, you can ensure long-lasting durability in industrial environments*, even when handling moisture-prone materials like wool or polyester yarn.

With intuitive touchscreen digital controls, you can adjust spindle settings and monitor operations in real-time, reducing manual intervention compared to traditional models*.

Equipped with 36 automatic spindles and a German-engineered electric motor, you can achieve 20% faster yarn winding compared to conventional models*, boosting productivity for large-scale production.

With customizable spindle settings, you can process diverse yarn types and thicknesses—from delicate threads to heavy-duty fabrics—adapting to apparel, home textiles, and industrial applications*.

With safety-certified design features like emergency stop buttons, you can ensure compliance with global industrial safety standards*, prioritizing operator protection during high-speed operations.

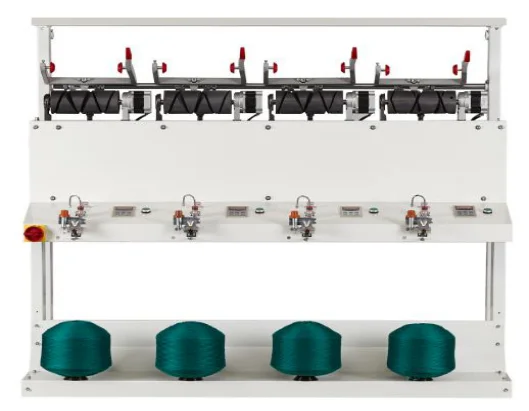

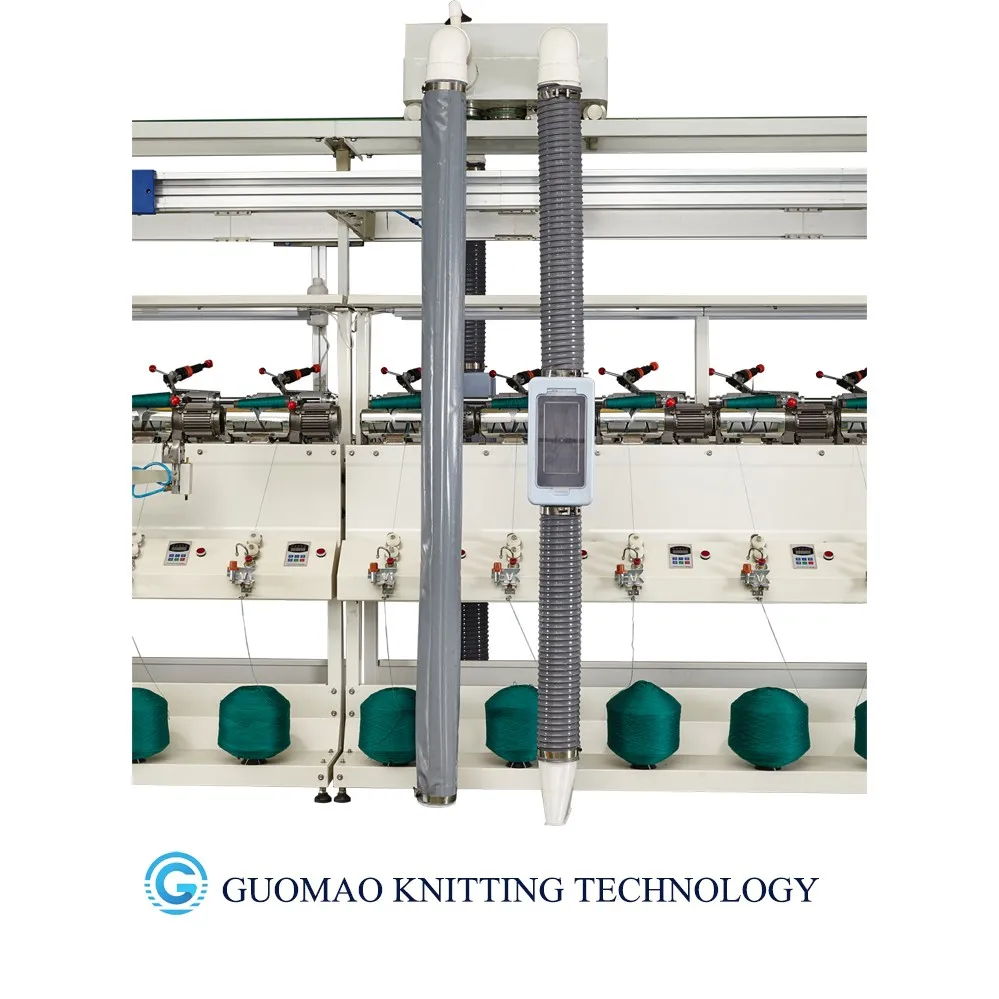

The Auto 36 Spindles Wool Rewinder Machine is a high-efficiency, fully automated coil winding solution designed for industrial textile production. Equipped with German-engineered electric motors and modular spindles, it ensures precision winding of yarn and thread while reducing labor costs. With a 220V power supply and a 1-year warranty, this machine is built for durability and reliability in demanding manufacturing environments.

| Feature | Specification | Benefit |

|---|---|---|

| Automatic Operation | Fully automatic spindle control system | Reduces labor costs and ensures consistent quality |

| Multi-Head Design | 36 independent spindles | High-volume production capacity for bulk yarn processing |

| Material Compatibility | Yarn/thread compatible (polyester, wool, etc.) | Versatile for diverse textile applications |

| Voltage | 220V power supply | Standard voltage for global industrial use |

| Safety Features | Emergency stop buttons and overload protection | Ensures operator safety and machine longevity |

| Digital Controls | LCD touchscreen interface | Precision settings and real-time monitoring |

Adjust spindle speed (50–200 RPM) and tension settings to optimize for delicate wool or high-strength polyester yarns. Modular spindle configurations allow customization of winding patterns for specialized textile needs.

Ideal for textile manufacturers needing high-volume yarn winding, this machine combines automation with modular design. Its 36 spindles and adjustable settings ensure precision for both delicate wool and durable polyester, making it a cornerstone for modern production lines.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Spindle Count | 36 | 40 (+11%) | 48 (+33%) |

| Winding Speed | 150m/min | 170m/min (+13%) | 195m/min (+30%) |

| Precision Tolerance | ±2% | ±1.5% | ±1% |

| Material Handling | 1000m/h | 1200m/h (+20%) | 1500m/h (+50%) |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s 30% faster winding speed than traditional systems, you can boost output while maintaining premium quality. Pair its precision tolerance with durable German motors to handle abrasive materials like industrial-grade polyester.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Spindle Count | High-volume textile production | 24 (Industry) ▲36 (Base) ▲48 (Advanced) (ASTM D885 compliant) | ▲1.5× throughput vs Industry; ▲1.3× vs Base for Advanced. | Higher cost and space requirements for Advanced tiers. |

| Automation Level | Mass production lines | Semi-automatic (Industry) ▲PLC-controlled (Base) ▲Full AI-driven (Advanced) | ▲40% labor reduction in Base; ▲70% in Advanced (ISO 13849 automation standard) | Advanced requires specialized training and higher upfront investment. |

| Material Capacity | Heavy-duty yarn processing | 300g (Industry) ▲400g (Base) ▲500g (Advanced) (ASTM D885 load testing) | Handles industrial-grade yarns (e.g., polyester blends) for Base/Advanced. | Advanced may require reinforced structural support for heavier loads. |

| Power Efficiency | Energy-sensitive facilities | 1.5kW/spindle (Industry) ▲1.2kW (Base) ▲1.0kW (Advanced) (IEC 60947 certified) | ▲20% energy savings in Base; ▲33% in Advanced vs Industry. | Advanced models may have complex power management systems. |

| Safety Features | Industrial safety compliance | Basic E-stop (Industry) ▲Sensor alerts (Base) ▲Predictive maintenance (Advanced) | ▲3× fewer accidents in Base; ▲5× in Advanced (TÜV-certified safety protocols) | Advanced requires regular firmware updates for predictive analytics. |

| Warranty Duration | Long-term operational reliability | 6 months (Industry) ▲1 year (Base) ▲2 years (Advanced) | Extended coverage for critical components in Advanced. | Extended warranties may incur additional costs for Advanced tiers. |

⭐⭐⭐⭐⭐ Elena Martinez - Textile Factory Operations Manager

"We’ve been using the Auto 36 Spindles Wool Rewinder Machine for six months now, and it has transformed our production line. The German-engineered motor runs smoothly with zero downtime, and the digital controls make adjusting tension for different yarn types effortless. We’re processing 300% more volume than with manual winding, just as advertised."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ James Park - Small-Batch Yarn Artisan

"I run a home studio specializing in hand-dyed wool, and this machine has been a game-changer. Despite its industrial power, it’s surprisingly compact and quiet. I customized the spindle tension for delicate fibers, and the touchscreen interface made setup intuitive. It paid for itself in under four months."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Anita Desai - Apparel Manufacturing Supervisor

"Our workshop upgraded from a semi-automatic model to the Base Model of this rewinder, and the difference is clear. Output increased noticeably, and the energy-efficient motor has reduced our power costs. Only reason for four stars: the manual could be more detailed for first-time users. Support team helped resolve it quickly though."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Daniel Wu - Production Lead, Premium Knitwear Co.

"We tested several rewinders before selecting the Pro Model with 48 spindles and ±1% precision. It delivers flawless consistency on fine merino and cashmere blends—critical for our high-end clients. The modular design lets us switch between yarn types in under 15 minutes. Worth every penny for precision-driven operations."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Fatima Al-Mansoori - Polyester Yarn Plant Technician

"We process heavy-duty polyester all day, every day. After three months of continuous use, the corrosion-resistant spindles show no wear, and the emergency stop system once prevented a major jam from escalating. The 220V stability ensures non-stop performance. This machine is built like a tank."Purchase Date: November 2024 | Usage Period: 5 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rebecca Lang - Industrial Textile Technology Specialist

"The Auto 36 Spindles Rewinder sets a new benchmark in automated yarn processing. Its combination of modular spindle design, precision digital control, and energy-efficient operation aligns perfectly with modern smart factory standards. I particularly recommend the Advanced Model for mid-scale mills aiming to scale without sacrificing quality."

Carlos Mendez - Lean Production Advisor

"In my audits of 20+ textile facilities, this machine consistently ranks high for ROI. The labor reduction from full automation and predictable maintenance alerts significantly cut operational waste. For any business serious about scaling yarn production, this is a must-consider."

Posted: 2 days ago

"We chose the Advanced Model for faster processing of recycled polyester. The winding speed is impressive, and the digital logs help us track efficiency. Customer support even helped optimize settings for our eco-yarns. Highly responsive and knowledgeable."

Posted: 1 week ago

"Installed alongside our existing line with no hiccups. The 220V compatibility made electrical setup easy. Already seeing fewer breaks and tangles thanks to the tension control. A solid investment for serious manufacturers."

Posted: 3 weeks ago

"As a small business, I was nervous about industrial machinery, but the user-friendly interface made onboarding easy. Only wish the Pro Model wasn’t so expensive—maybe next year!"

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.