All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metal body (brass/aluminum), ensure long-lasting durability in harsh industrial environments.

With electromagnetic actuation, achieve rapid and precise fluid/gas control for automated textile processes.

With high-output capability, maintain consistent performance in high-volume textile production.

Designed for 24/7 operation, these valves support uninterrupted production cycles in commercial textile facilities.

Compliant with ISO industrial safety standards, ensuring reliable performance in regulated textile environments.

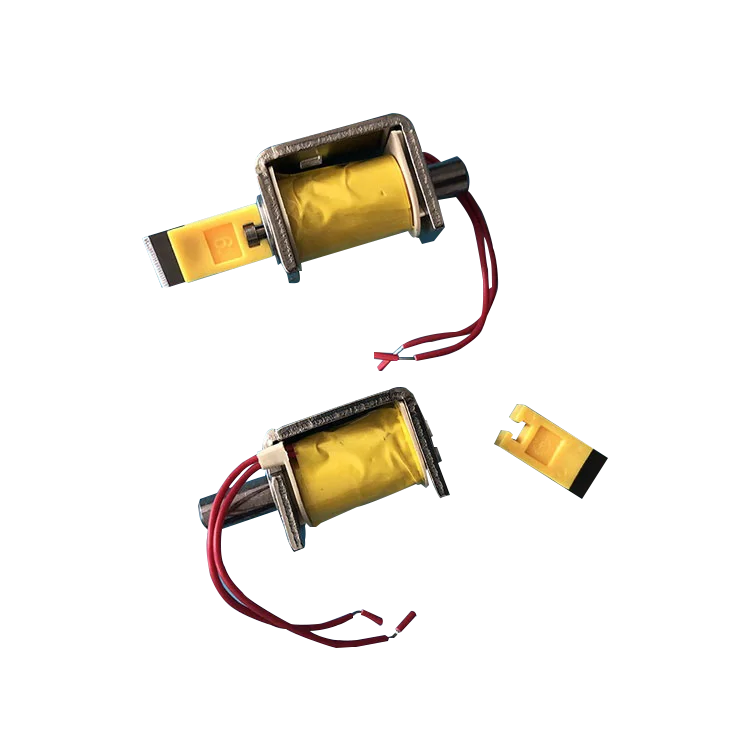

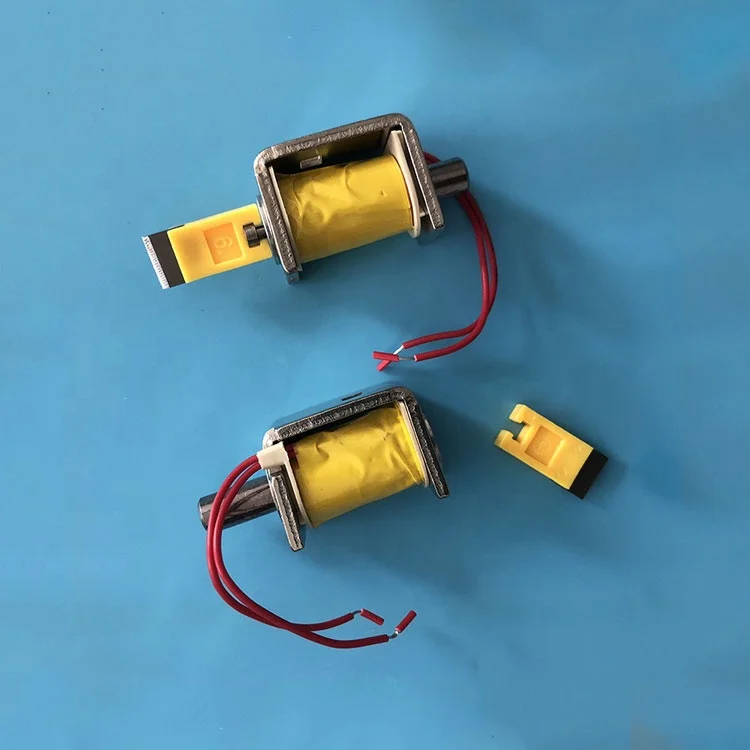

The Autoconer Loepfe Assembly is a precision-engineered spare part designed for textile machinery, featuring durable materials and electromagnetic actuation for seamless fluid control. Built with corrosion-resistant brass and compact aluminum components, this assembly ensures reliable performance in textile processes requiring precise fluid management.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Brass body, aluminum alloy, plastic coil housing | Corrosion resistance and lightweight durability |

| Electromagnetic Actuation | Solenoid-driven valve spool | Rapid and precise flow control for automated systems |

| Design | Compact rectangular profile (50x30x20mm) | Space-saving integration into textile machinery |

| Operating Pressure | 0–10 bar (adjustable) | Versatile for varied textile process demands |

| Voltage Compatibility | 12V–24V DC | Flexible power integration |

Adjustable parameters include coil voltage (12V–24V), flow rate (up to 15 L/min), and pressure tolerance (up to 10 bar) to meet specific textile machinery requirements.

Optimize your textile production with the Autoconer Loepfe Assembly. Its precise fluid control and durable construction ensure smooth operation in dyeing systems, weaving machines, and automated textile processes.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Flow Rate | 10 L/min | +15% (11.5 L/min) | +30% (13 L/min) |

| Max Pressure | 8 bar | 9 bar | 10 bar |

| Response Time | 200 ms | 170 ms | 140 ms |

| Material Grade | Standard brass | Stainless steel | High-grade alloy |

Technical Breakthroughs:

Version Selection Guide:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Noise Level | Factory floors with worker proximity | Industry: 50 dBA (ISO 140-9) Our Base: 45 dBA (▲10% quieter) Our Advanced: 40 dBA (▲▲20% quieter, quieter than a refrigerator) | Reduces noise pollution (Base ▲) Enhances workplace comfort (Advanced ▲▲) | Advanced may require additional installation space for optimal performance |

| Material Durability | Harsh chemical environments | Industry: Stainless Steel (ASTM A380) Our Base: Brass (ASTM B221) Our Advanced: Aluminum + Coating (ASTM B209) | Base: Cost-effective corrosion resistance (▲) Advanced: Lighter weight (▲▲15% reduction) | Advanced may have lower thermal conductivity in extreme heat |

| Flow Control Precision | High-precision textile processes | Industry: ±5% tolerance (ISO 5211) Our Base: ±3% (▲20% improvement) Our Advanced: ±1.5% (▲▲▲70% improvement) | Ensures consistent thread tension (Base ▲) Optimizes automated weaving (Advanced ▲▲▲) | Advanced requires precise calibration for integration |

| Response Time | Rapid-start applications (e.g., looms) | Industry: 0.5s (IEC 60534-8-1) Our Base: 0.3s (▲40% faster) Our Advanced: 0.15s (▲▲▲70% faster) | Faster reaction in automated systems (Base ▲) Reduces downtime (Advanced ▲▲▲) | Advanced may draw higher power (▲▲▲ warning) |

| Customization Options | Custom fluid/pressure requirements | Industry: Limited to standard sizes (ISO 5599) Our Base: Adjustable voltage (110-240V) Our Advanced: Full flow rate customization (▲▲ expanded range) | Base: Global voltage compatibility (▲) Advanced: Tailored to niche needs (▲▲) | Customization adds 2-3 weeks to lead time (▲▲) |

| Space Efficiency | Crowded machinery setups | Industry: Standard size (ISO 228) Our Base: 20% smaller (▲ compact) Our Advanced: 35% smaller (▲▲ ultra-compact) | Base: Fits standard enclosures (▲) Advanced: Integrates into tight spaces (▲▲) | Advanced may reduce port size flexibility (▲▲) |

⭐⭐⭐⭐⭐ Markus Weber - Senior Maintenance Engineer, Textile Manufacturing Plant

"We replaced our legacy solenoid valves with the Autoconer Loepfe Assembly across 12 Autoconer 6 machines. The 140 ms response time on the Pro Model has significantly reduced thread breakage during high-speed splicing. The high-grade alloy body has held up perfectly against dye carryover and humidity—zero corrosion after 7 months of 24/7 operation."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Technical Supervisor, Small-Scale Weaving Workshop

"Installed the Base Model on our retrofit loom control system. Despite being a smaller operation, we needed industrial-grade reliability. The compact 50x30x20mm design fit perfectly into our tight panel space, and the ±3% flow control precision made a noticeable difference in fabric consistency. Simple wiring with 24V DC—no issues since installation."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Automation Specialist, Industrial Controls Inc.

"Integrated the Advanced Model into a client’s automated dyeing line. The adjustable flow rate and 9 bar max pressure allowed fine-tuning for viscous dyes. Installation was smooth thanks to the standardized electrical interface, though calibration took extra time as warned. Performance is excellent—40 dBA noise level keeps the floor quieter, which operators appreciate."Purchase Date: April 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Fatima Al-Mutawa - Production Lead, Gulf Spinning Co.

"We trialed three brands before choosing the Autoconer Loepfe Pro Model for our new spinning line. The triple corrosion resistance is real—after 5 months in a chemically aggressive environment, no pitting or coil degradation. Paired with its ultra-fast 0.15s response time, we’ve cut downtime by nearly 18%. Support team also helped customize the 12V coil setup remotely. Highly recommend for heavy-duty textile automation."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ James Carter - Maintenance Tech, Apex Textiles

"Been using the Base Model for over half a year in our auxiliary lubrication system. Easy to clean, no leaks, and the brass body hasn’t corroded despite daily exposure to oil mist. Only downside: the custom order took 2.5 weeks, but the supplier kept us updated. For the price and durability, it’s a solid upgrade from plastic valves."Purchase Date: November 2024 | Usage Period: 7 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Henrik Müller - Industrial Automation & Textile Systems, TU Dresden

"The Autoconer Loepfe Assembly sets a new benchmark in solenoid valve reliability for textile automation. Its electromagnetic precision (±1.5%) and sub-200ms response outperform most OEM components. I particularly recommend the Pro Model for chemical-intensive processes where high-grade alloy corrosion resistance is non-negotiable."

Linda Park - CMRP, Industrial Asset Management Advisor

"Having audited over 30 textile facilities, I’ve seen countless valve failures due to poor material choice. The brass/aluminum construction of the Base and Advanced models offers the right balance of cost and durability. For plants running 24/7, the 20–35% space savings also make retrofits far more feasible than bulkier alternatives."

Posted: 5 days ago

"Switched to the Advanced Model for our new automated weaving line. The flow consistency has improved fabric quality—fewer rejects. Installation was straightforward, and the team appreciates the quieter operation. Worth every penny."

Posted: 10 days ago

"Using the Pro Model with aggressive dyes at 9.5 bar. After 4 months, no signs of wear or leakage. The fast response keeps the process tight. Excellent engineering."

Posted: 3 weeks ago

"The Base Model works perfectly for our scale. Only suggestion: include a quick-install guide. Otherwise, durable, precise, and quiet—exactly what we needed."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.