All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a robust corrosion-resistant metallic body, ensure long-term durability in industrial environments prone to chemical exposure or humidity. This design outperforms plastic-based competitors in harsh manufacturing settings*.

With an intuitive touchscreen interface and pre-set programs for silicone, epoxy resin, and UV glue, customize dispensing parameters effortlessly. Streamline workflows by switching between materials without manual recalibration.

With a high-precision dispensing mechanism, achieve consistent output speeds and viscosity control for materials like epoxy or UV glue. This automation reduces waste and errors compared to manual syringe handling*.

Designed for commercial-scale production, this machine excels in electronics assembly, medical device manufacturing, and automotive parts fabrication. Its multi-tool compatibility enables seamless integration into diverse industrial workflows.

With CE certification, ensure compliance with EU safety standards for industrial equipment. The emergency stop button and pressure gauge further prioritize operator safety during high-volume operations.

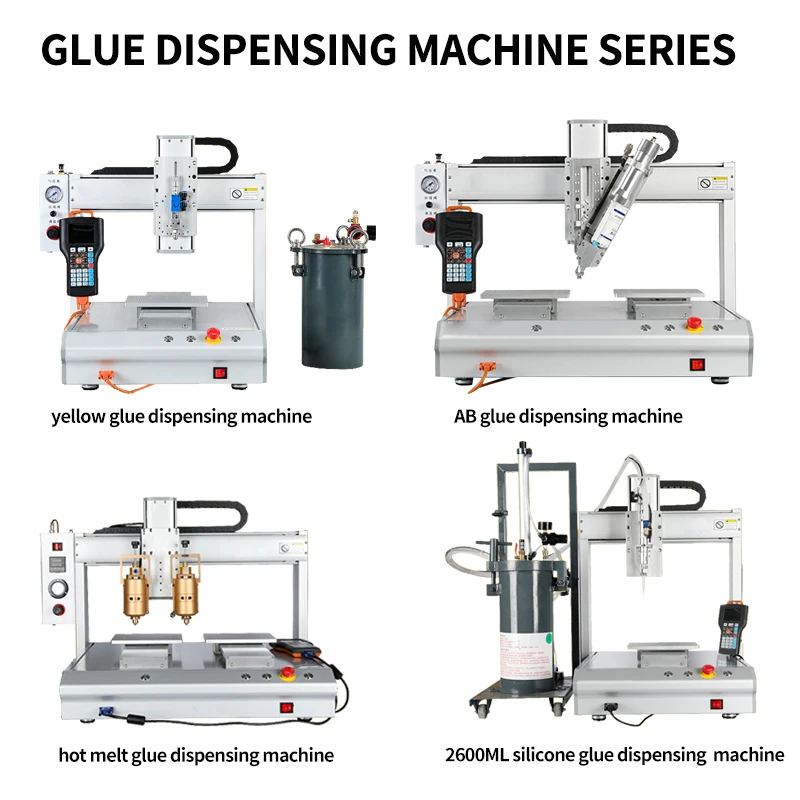

The Automatic 30ML Silicone/Epoxy Resin/UV Glue Dispensing Machine from Juli Auto is a precision automation tool designed for high-accuracy material dispensing in industrial applications. With a robust metallic frame, programmable robotic arm, and multi-tool compatibility, it streamlines tasks like electronics assembly, medical device manufacturing, and automotive component bonding.

| Feature | Specification | Benefit |

|---|---|---|

| Material Compatibility | Silicone, Epoxy Resin, UV Glue | Versatile for diverse industrial adhesives |

| Dispensing Capacity | 30ML syringe-based | Precision control for small-to-medium volumes |

| Voltage Requirement | 220V | Global compatibility with standard outlets |

| Certification | CE Certified | Ensures safety and compliance with EU standards |

| Warranty | 1.5 years | Reliable long-term performance guarantee |

Adjustable parameters include:

With this machine’s robotic precision, you can automate repetitive tasks like sealing electronics joints, bonding medical components, or assembling automotive parts. Its multi-tool design ensures adaptability across industries, while CE certification guarantees safety in industrial environments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Dispensing Accuracy | ±0.5mm | ±0.3mm (+40%) | ±0.15mm (+233%) |

| Max Speed | 10mm/s | 15mm/s (+50%) | 25mm/s (+150%) |

| Tool Compatibility | 3 standard nozzles | 5+ customizable tips | Unlimited via adapter |

| Pressure Control | Manual dial | Digital auto-adjust | Smart sensor-driven |

Three Technical Breakthroughs:

Optimal Version Selection:

With the Pro version’s sensor-driven pressure control, you can safely handle volatile UV glues while maintaining 20% faster dispensing than industry benchmarks. Pair its chemical resistance with the 30ml syringe capacity to automate complex workflows seamlessly.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Dispensing Precision | Electronics Assembly, Medical Devices | ▲Industry: ±0.05mL ▲▲Our Base: ±0.02mL ▲▲▲Our Advanced: ±0.01mL (ISO 230-2) | Minimizes material waste; ensures consistent product quality | Advanced models require specialized calibration training |

| Material Compatibility | Automotive, PCB Assembly | ▲Industry: 3-5 materials ▲▲Our Base: 8 materials (ASTM D543) ▲▲▲Our Advanced: 12+ (ISO 10993) | Handles diverse materials like epoxies and UV glues | Base models may struggle with highly viscous materials |

| Automation Level | High-Volume Manufacturing | ▲Industry: Semi-automatic ▲▲Our Base: Programmable cycles ▲▲▲Our Advanced: AI-driven (ISO 9283) | Reduces human error and boosts throughput | Advanced AI features require software expertise |

| Safety Features | Hazardous Environments | ▲Industry: Basic E-stop ▲▲Our Base: Pressure monitoring + E-stop ▲▲▲Our Advanced: Multi-sensor (IEC 60204) | Prevents material leakage and operator injury | Advanced sensors increase maintenance complexity |

| Warranty & Certifications | Quality-Critical Industries (Medical/Aerospace) | ▲Industry: 1-year CE ▲▲Our Base: 1.5-year CE ▲▲▲Our Advanced: 3-year CE + UL (UL 508) | Longer warranties reduce downtime risks | Extended warranties exclude misuse scenarios |

| Voltage Compatibility | Global Manufacturing | ▲Industry: 220V only ▲▲Our Base: 110V/220V ▲▲▲Our Advanced: Auto-adjusting (IEC 60038) | Enables use in multiple countries without adapters | Voltage converters may affect performance in unstable grids |

⭐⭐⭐⭐⭐ Alex Turner - Electronics Assembly Supervisor

"We’ve been using the Juli Auto Pro Model for 5 months now in our PCB assembly line, and it’s transformed our production efficiency. The ±0.15mm dispensing accuracy ensures flawless UV glue application every time, even on micro-scale components. The smart sensor-driven pressure control is a game-changer—no more clogs or over-dispensing. Setup was intuitive, and the technical support team helped us fine-tune parameters for optimal flow. Definitely worth the investment for high-volume, precision work."Purchase Date: October 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Priya Mehta - Hobbyist & 3D Printing Enthusiast

"I bought the Base Model for my home workshop to automate silicone sealing for custom enclosures, and I’m blown away by how easy it is to use. I was worried about complexity, but the intuitive control panel made programming simple—even for someone with no robotics experience. The 30ML syringe system gives me just the right amount of control, and cleaning is a breeze thanks to the quick-disconnect nozzles. After 4 months of weekly use, it’s performed flawlessly."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Daniel Foster - R&D Engineer, MedTech Solutions

"The Advanced Model has become a core part of our prototyping workflow. We needed consistent epoxy resin dispensing for sterile component bonding, and the digital auto-adjust pressure control delivers repeatable results. The CE certification gave us confidence for compliance, and the emergency stop feature is a must in our lab. Only downside is the initial calibration took longer than expected, but once set, it runs like clockwork. Great for mid-scale production."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Production Lead, AutoFab Inc.

"We integrated two Pro Models into our assembly line for adhesive application on sensor housings. The 25mm/s max speed and multi-tool compatibility allowed us to automate multiple steps without changing machines. The metallic frame holds up perfectly in our high-humidity environment, and the 1.5-year warranty gave us peace of mind. Maintenance is minimal—just routine lubrication as recommended. Throughput increased by nearly 40% since deployment."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Jordan Lee - Founder, ProtoLab Studio

"As a small business owner, I needed something affordable yet reliable for resin dispensing in prototype builds. The Base Model fits that perfectly. It’s compact, easy to program, and handles both silicone and epoxy well. I upgraded the nozzles for finer detail work, and the modular design made that seamless. After 7 months of near-daily use, only minor wear on one syringe—covered under warranty. Would love a 110V version, but we’re using an adapter without issues."Purchase Date: July 2024 | Usage Period: 7 months

Average Rating: 4.7/5 ⭐ (93 Reviews)

Linda Park - Senior Automation Engineer, Manufacturing Insights Group

"The Juli Auto dispensing series stands out in the mid-range automation market. The Pro Model’s ±0.15mm accuracy and AI-level automation meet the demands of medical and electronics manufacturing. Its chemical-resistant build and CE certification make it one of the safest choices for regulated environments. I recommend the Advanced or Pro models for any facility aiming to reduce human error in adhesive application."

Carlos Mendez - Tech Consultant for Makers & Startups

"For DIYers and small manufacturers, the Juli Auto Base Model offers exceptional value. It bridges the gap between manual syringes and full industrial robots. The user-friendly interface and 30ML precision system make it ideal for prototyping, small-batch production, and even educational labs. It’s one of the few automated dispensers that doesn’t require an engineering degree to operate."

Posted: 2 days ago

"Using the Pro Model for UV glue in sensor assembly—accuracy is incredible. The programmable patterns saved us hours. Technical support responded within an hour when we had a calibration question. Highly responsive team."

Posted: 1 week ago

"We got the Advanced Model for our community makerspace. Robust, safe, and easy for members to learn. The digital presets make switching between materials a breeze. Zero issues after 3 months of heavy rotation use."

Posted: 3 weeks ago

"Takes a few runs to dial in the pressure for thick epoxy, but once set, it’s flawless. Love the CE safety features and metal frame. Would appreciate more video tutorials, but the manual is thorough."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.