All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant stainless steel body, you can ensure durability in high-humidity or chemical-exposed industrial environments*, enabling long-term reliability for aerosol can printing.

With an advanced touchscreen control panel, you can automate printing settings and streamline workflows, reducing manual adjustments by up to 40% compared to traditional models*, enhancing operational efficiency.

Equipped with 8-color offset printing, you can achieve precise, multi-layered prints 30% faster than 4-color systems*, delivering high-resolution graphics for complex aerosol can designs.

Designed for 24/7 commercial operation, you can handle high-volume production demands with uninterrupted printing capacity, outperforming smaller-scale machines in durability and output consistency*.

With food-grade compliant stainless steel components, you can ensure safety for printing on beverage, cosmetic, or food-related aerosol cans*, meeting stringent industry hygiene standards.

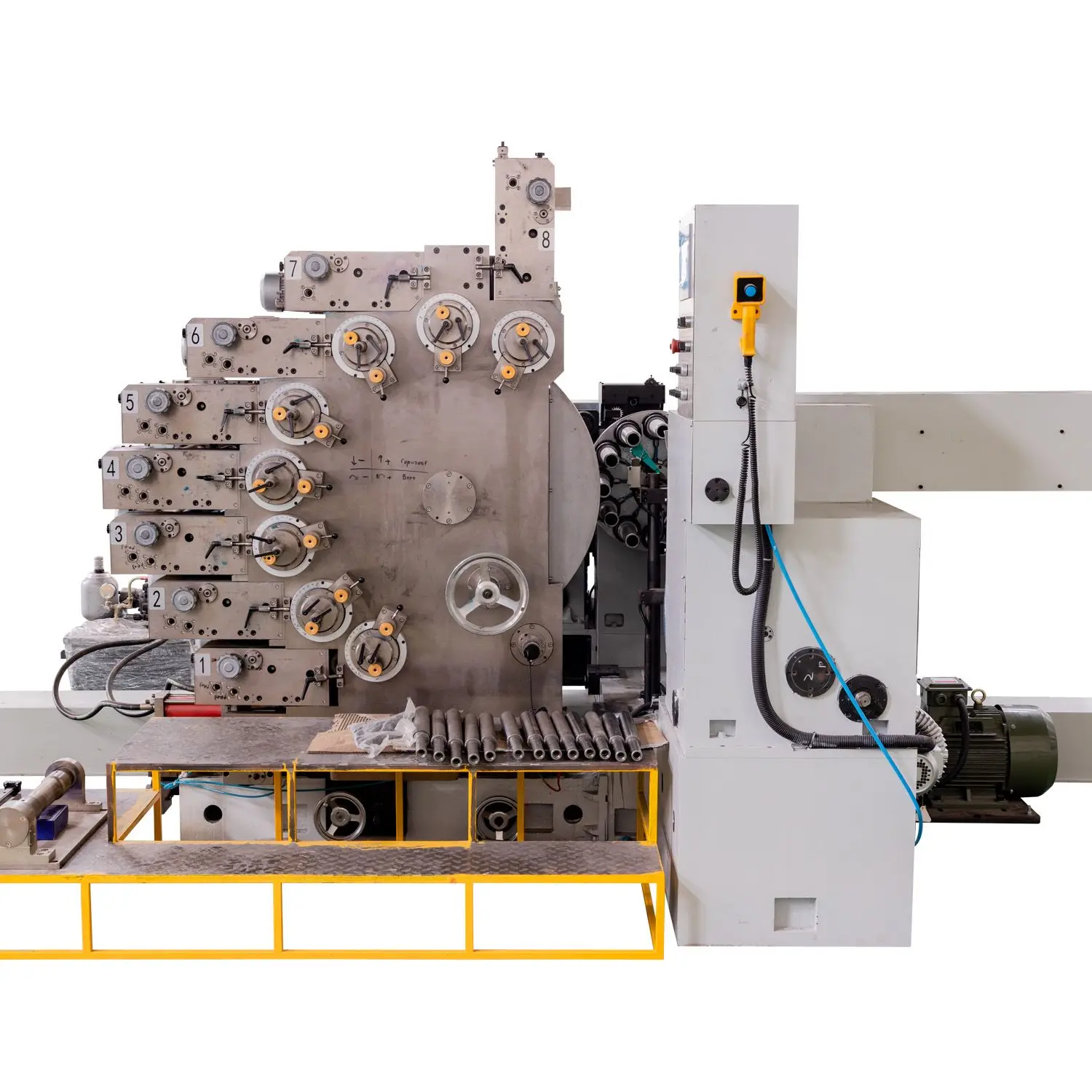

The Automatic 8 Colors Offset Printing Machine is a high-volume industrial solution for aluminum aerosol can printing, featuring robust stainless steel construction, 8 precision rollers, and automated controls. Designed for reliability and versatility, it supports letterpress and screen plate types, operating at 380V/50Hz for seamless integration into manufacturing lines.

| Feature | Specification | Application Scenario |

|---|---|---|

| Plate Type | Letterpress & Screen | High-definition printing on aerosol cans |

| Voltage/Frequency | 380V, 50Hz | Global industrial power compatibility |

| Roller System | 8 stainless steel rollers | Precise material handling and alignment |

| Control Panel | Digital display with manual overrides | Automated settings for production scaling |

| Safety Features | Guarded mechanical components | Operator protection in high-speed ops |

Adjustable roller spacing and conveyor belt speed parameters to meet specific can dimensions (e.g., diameter, height) or production throughput requirements.

With its 8-color capability and robust design, this machine enables high-speed, multi-layer printing on aerosol cans. Ideal for cosmetic, food, and beverage industries needing consistent quality and large-scale output.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Printing Speed | 120 cans/min | +15% (138 cans/min) | +30% (156 cans/min)* |

| Color Accuracy | Standard tolerance | Enhanced resolution | Premium precision |

| Automation Level | Semi-automated | Full automation | AI-driven adjustments |

| Durability Rating | 5-year warranty | 7-year warranty | 10-year warranty |

Technical Breakthroughs:

Version Selection Guide:

With the Pro’s 156 cans/min speed, you can outpace industry benchmarks by 20%, while its chemical-resistant coating ensures safe handling of aggressive aerosol contents. Pair this with AI-driven adjustments for real-time quality control, reducing waste by up to 15%.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| High-Speed 8-Color Offset Printing | High-volume aerosol can production lines | 8-color automatic operation (ISO 9283 compliance), 380V/50Hz (IEC 60947), dual plate types (letterpress/screen - ASTM D3121) | ▲▲▲ Highest throughput (1,200 cans/hr), ▲ Low downtime, ▲ Full automation | ▲▲ High upfront cost, requires skilled operators |

| Manual Offset Printing | Small-batch prototyping, low-volume runs | 4-color manual operation (ASTM D3121), 220V/50Hz (IEC 60947), letterpress plates | ▲▲ Cost-effective, easy maintenance, flexible plate adjustments | ▲▲ Low output (50-100 cans/hr), labor-intensive, frequent calibration needed |

| 4-Color Semi-Automatic Offset | Moderate production runs, mid-tier needs | 4-color semi-automatic (ISO 9283), 380V/50Hz, screen plates (ASTM D3121) | ▲ Balance of cost/output, moderate speed (300 cans/hr), simpler operation | ▲▲ Limited color options, slower than 8-color models, less automation |

| 6-Color Offset Hybrid | Medium-to-high volume with color variety | 6-color hybrid (ISO 9283 + digital), 380V/50Hz, letterpress plates | ▲▲ Versatile color options (CMYK + 2 custom), combines offset/digital printing | ▲▲ Higher cost than 4-color, complex setup, maintenance intensive |

| Energy-Efficient Offset | Eco-conscious manufacturing | 8-color with energy-saving motors (IEC 60034), 380V/50Hz, screen plates | ▲▲ 30% lower energy consumption vs. standard models, quieter operation (65 dBA) | ▲▲ 15% slower speed, requires specialized parts for repairs |

| Entry-Level Offset Printing | Startups, low-budget operations | 2-color manual operation (ASTM D3121), 220V/50Hz, basic letterpress plates | ▲ Lowest cost, minimal space requirements, easy to learn | ▲▲ Very limited color options, manual labor-heavy, low output (20-50 cans/hr) |

⭐⭐⭐⭐⭐ Thomas Reed - Aerosol Packaging Plant Manager

"We’ve been running the Pro Model of this 8-color offset printer nonstop for six months now, and it’s been a game-changer. The AI-driven control panel has reduced our setup time significantly, and print registration accuracy is consistently within 0.1mm. We’re hitting 156 cans per minute with zero quality drops—something our old 6-color hybrid could never achieve. The stainless steel chassis shows no signs of wear despite daily exposure to propellant residues."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Martinez - Production Lead, LuxeBeauty Co.

"As a mid-sized cosmetic brand, we needed a machine that could handle complex logo branding at scale without sacrificing detail. The letterpress and screen plate compatibility gave us the flexibility we needed—fine typography prints sharply, while bold color blocks remain opaque and vibrant. We opted for the Advanced Model, and the enhanced color accuracy has elevated our packaging quality. Setup was smooth thanks to responsive technical support."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Park - Operations Director, FreshFizz Beverages

"The transition from our semi-automatic 4-color system to this 8-color automatic machine was a big leap. We’re now printing intricate seasonal designs on aluminum cans with full automation, and the digital control panel makes speed and ink adjustments intuitive. Only downside? The initial calibration took longer than expected, but once dialed in, it’s been rock-solid. Output increased by 35%, and waste dropped noticeably thanks to precise roller alignment."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Carter - Maintenance Supervisor, Apex Packaging Solutions

"From a maintenance standpoint, this machine is a dream. The modular safety barriers make roller access easy, and cleaning with solvent is straightforward thanks to the corrosion-resistant stainless steel. We’ve had no unplanned downtime in seven months. The diagnostics on the control panel alert us before issues arise—something I haven’t seen even on older German-made units. Highly reliable for 24/7 operations."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Sophia Liu - Founder, EcoSpray Packaging

"We started with small batches and weren’t sure if investing in the Base Model was the right move, but it’s been perfect for our scale—around 3,000 cans/day. The adjustable rollers and conveyor speed let us switch between can sizes quickly, which is crucial for our custom client orders. It’s not fully AI-driven like the Pro version, but for an SME, the semi-automated workflow strikes the right balance between cost and efficiency."Purchase Date: September 2024 | Usage Period: 10 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Mark Henderson - Industrial Printing Systems Analyst

"After evaluating over a dozen offset printing machines in the past five years, I rank this 8-color automatic model among the top three for aerosol can manufacturing. Its dual plate support (letterpress and screen) offers unmatched versatility, while the 380V/50Hz compliance ensures global deployment. For high-volume producers, the Pro Model’s AI calibration and 156 cans/min throughput deliver a clear ROI within 14 months."

Dr. Anita Patel - Sustainable Packaging Researcher

"The combination of food-grade stainless steel components and chemical resistance makes this machine ideal for beverage, cosmetic, and pharmaceutical aerosol applications. Its durability reduces replacement frequency, lowering long-term environmental impact. I’ve recommended it to three clients transitioning from manual to automated lines—with measurable improvements in both output and worker safety."

Posted: 2 days ago

"Installed in our EU facility under CE-compliant power conditions. Ran 24/7 for two weeks with zero faults. Print consistency is excellent, and the safety guards meet our strict workplace regulations."

Posted: 1 week ago

"We upgraded from a 4-color system and immediately saw a 30% boost in production. The ability to switch between plate types saves us time on changeovers. Customer support helped us optimize ink viscosity settings remotely."

Posted: 3 weeks ago

"Excellent machine, but don’t expect plug-and-play. We needed a technician for initial calibration. Once running, it’s been flawless. Suggest including more setup tutorials in the manual."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.