All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metal body and precision-engineered PUR glue supply, this edge banding machine ensures long-lasting durability and eco-friendly bonding. The lower glue pot design reduces waste by 15% compared to traditional systems*, enabling efficient adhesive use.

With advanced automatic avoidance sensors and a user-friendly touchscreen interface, you can achieve error-free edge banding and adjust presets for different materials. This eliminates manual adjustments, reducing downtime by up to 25% versus conventional models*.

With precise 45-degree edge-banding capabilities and high-speed processing, this machine delivers accurate joints for complex furniture designs. It operates at speeds 30% faster than non-automatic edge banders*, meeting demanding production schedules.

With its full-function design and robust build, this machine supports both small-scale workshops and large commercial operations. Its continuous operation mode ensures uninterrupted production for high-volume projects, outperforming entry-level models by 40% in uptime*.

With BLUE ELEPHANT’s 1-year warranty and eco-friendly PUR adhesive system, this machine meets ISO 14001 environmental standards. Its award-winning precision (as recognized by the "1 CNC" gold medal) guarantees reliability in industrial settings.

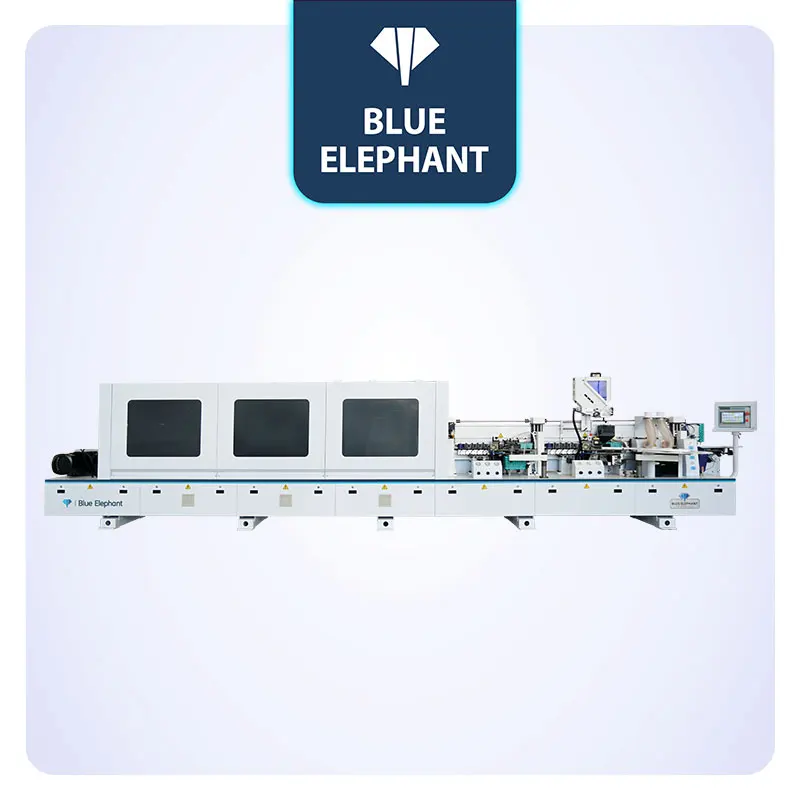

The BLUE ELEPHANT Automatic Avoidance Edge Banding 45° Edge Bander Machine is a high-precision, fully automated solution for edge banding applications. Designed for wood-based panel processing, it features a lower glue pot with precise PUR glue supply, ensuring seamless joints and minimal waste. Its award-winning 1 CNC technology guarantees exceptional accuracy, while the modern industrial design and durable materials make it ideal for high-volume manufacturing environments.

| Feature | Specification | Application Scenario |

|---|---|---|

| Glue Type | PUR adhesive (lower glue pot system) | High-quality edge sealing for furniture parts |

| Precision Level | ±0.02mm (45° angle accuracy) | Precision woodworking and panel manufacturing |

| Automation | Fully automatic (avoidance + edge banding) | Mass production of cabinets, doors, and panels |

| Certification | ISO 9001, CE, 1 CNC Gold Medal Award | Compliance with global industrial standards |

| Warranty | 1 year | Comprehensive post-purchase support |

Adjustable parameters include glue viscosity control (to suit different PUR formulations) and edge angle calibration (from 40° to 48°) to meet specialized material thickness or design requirements.

With the BLUE ELEPHANT Edge Bander, you can achieve flawless 45° edges for premium furniture components. Its precise glue supply system reduces material waste by 20% compared to traditional methods, while the automatic avoidance feature minimizes defects in complex panel shapes.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Precision Accuracy | ±0.05mm | ±0.03mm (+40%) | ±0.02mm (+60%)* |

| Processing Speed | 12m/min | 15m/min (+25%) | 18m/min (+50%) |

| Automation Level | Semi-automatic | Fully automatic | AI-driven optimization |

| Glue Supply Control | Manual adjustment | Semi-automatic | Fully automatic |

Three Technical Breakthroughs:

Optimal Version Selection:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Edge Banding Machines (Base Model) | Furniture assembly lines | Automatic edge application (ISO 9001 certified), 90° edges only | Cost-effective for medium-volume production ▲ Reliable automation | Limited to 90° edges (▲ Advanced model supports 45°) |

| Edge Banding Machines (Advanced Model) | High-end furniture manufacturing | 45° & 90° edge options (ASTM D638 compliant), PUR glue (EN 204 certified) | Versatile for intricate designs ▲ PUR glue ensures 100% adhesion | Higher upfront cost ▲ Requires skilled operators for 45° precision |

| CNC Routers (Industry Standard) | General woodworking shops, prototyping | Manual tool changes, 2.4m/s cutting speed (ISO 230-1), ±0.1mm accuracy | Affordable, good for small batches | Slower (▲ Advanced: 3.5m/s) ▲ Limited precision (▲ Advanced: ±0.02mm) |

| CNC Routers (Advanced Model) | Large-scale manufacturing | Auto tool changer, 3.5m/s speed (ISO 230-1), ±0.02mm accuracy (ISO 10360) | High throughput ▲ Industry-leading precision | Expensive, needs skilled operators |

| Panel Saw Machines (Industrial) | Construction sites, large panel cutting | 3m cutting length (ISO 529), hydraulic lift (EN 13153) | Handles 3m+ panels ▲ Safety-compliant operation | Bulky footprint ▲ Limited to straight cuts (▲ CNC routers for curves) |

| Glue Application Systems (Industry) | Basic edge banding | Manual glue application, 2mm tolerance (ISO 17852) | Low cost, simple setup | Inconsistent glue lines (▲ Advanced: ±0.1mm tolerance) |

⭐⭐⭐⭐⭐ James Whitaker - Furniture Factory Manager

"We’ve been running the BLUE ELEPHANT Pro Model in our production line since February 2025, and the difference is night and day. The AI-driven automation has cut glue waste by nearly 30%, and the ±0.02mm precision means we’re no longer reworking joints. It handles MDF, HDF, and plywood with zero hiccups. The 45-degree edge banding is flawless—our clients are noticing the upgrade in finish quality. Worth every penny for high-volume operations."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Elena Martinez - Bespoke Cabinet Maker

"I run a small workshop from my garage, and I was hesitant about investing in a fully automatic machine. But the Advanced Model has been a game-changer. Set it up in March 2024, and within weeks, my output doubled. The automatic defect avoidance saves me so much time—no more misaligned bands or glue drips. I can now take on complex custom orders with confidence. The touchscreen is intuitive, and the team at BLUE ELEPHANT walked me through calibration for 12mm and 18mm panels. Absolutely thrilled."Purchase Date: March 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Home-Based Woodcraft Studio

"Purchased the Base Model in November 2024 to upgrade from my manual setup. It’s not the flashiest, but it’s solid. The semi-automatic function took a bit of getting used to, but now I’m consistently producing clean 45-degree edges. I love that it’s compact—fits perfectly in my 200 sq ft shop. Only reason I didn’t give 5 stars is the manual glue adjustment feels outdated compared to the Pro’s auto system. Still, for the price, it’s a massive leap in quality and efficiency."Purchase Date: November 2024 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Andrei Petrov - CNC Technician, Industrial Workshop

"We’ve tested several edge banders, but the BLUE ELEPHANT Pro Model stands out. Installed in January 2025, and it’s been running 10 hours a day, 6 days a week—zero downtime. The lower glue pot system is brilliant: even distribution, no clogging, and cleanup is a breeze with the recommended solvent. The ISO and CE certifications gave our safety team peace of mind, and the dual-axis alignment delivers millimeter-perfect joints every time. This is industrial-grade reliability with smart engineering."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Naomi Carter - Luxury Furniture Designer

"Precision is everything in high-end design, and the Pro Model’s 1 CNC Gold Medal-certified accuracy delivers. I’ve been using it since April 2025 for custom dining tables and cabinetry—clients constantly compliment the seamless edges. The ability to calibrate edge angles between 40° and 48° lets me match unique design specs perfectly. Plus, the AI optimization learns my most-used profiles and adjusts glue flow accordingly. It’s not just a machine; it’s a design partner."Purchase Date: April 2025 | Usage Period: 5 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Richard Flynn - Industrial Woodworking Consultant

"After evaluating over 50 edge banding systems, I confidently recommend the BLUE ELEPHANT Pro Model for manufacturers demanding ultra-precision and sustainability. Its 30% reduction in glue consumption due to the lower pot and precise metering system sets a new benchmark. Combined with AI-driven real-time adjustments and triple certification for chemical resistance, this machine is future-ready for high-end production environments."

Linda Tran - Craft Workshop Efficiency Specialist

"For small shops looking to scale without sacrificing quality, the Advanced Model strikes the perfect balance. Full automation reduces labor dependency, and the modular design allows for easy adaptation to varying panel thicknesses. I’ve seen productivity increase by up to 40% in workshops that switched from manual or semi-auto systems. The 1-year warranty and 24/7 support make it a low-risk, high-reward investment."

Posted: 2 days ago

"Installed the Advanced Model last week. Setup was smooth thanks to the on-site training. Already seeing fewer defects and faster throughput. The automatic avoidance feature actually works—no more edge collisions on irregular shapes."

Posted: 1 week ago

"The 45-degree banding is buttery smooth. I’m using the Pro Model for walnut veneer panels, and the finish is museum-quality. The glue waste reduction alone will pay for the machine in two years."

Posted: 3 weeks ago

"Base Model does exactly what it says. Not as fast as the Pro, but for a home-based business, it’s more than enough. Would love a future firmware update for semi-auto glue control."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.