All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

Material Technology: With a corrosion-resistant metal body and high-precision gear-and-bearing core components, ensure long-term durability in industrial environments.

Interactive Design: With a user-friendly control panel featuring preset buttons and real-time status indicators, streamline operations and reduce setup time.

Performance Parameters: With a 380V power supply and robust roller system, achieve consistent beveling precision across diverse pipe materials and thicknesses.

Scenario Solutions: With four-wheel mobility and modular design, adapt seamlessly to workshop layouts and customize workflows for pipe processing needs.

Certification Standards: With safety-certified construction (e.g., CE/ISO compliance*), meet rigorous workplace safety and operational reliability standards.

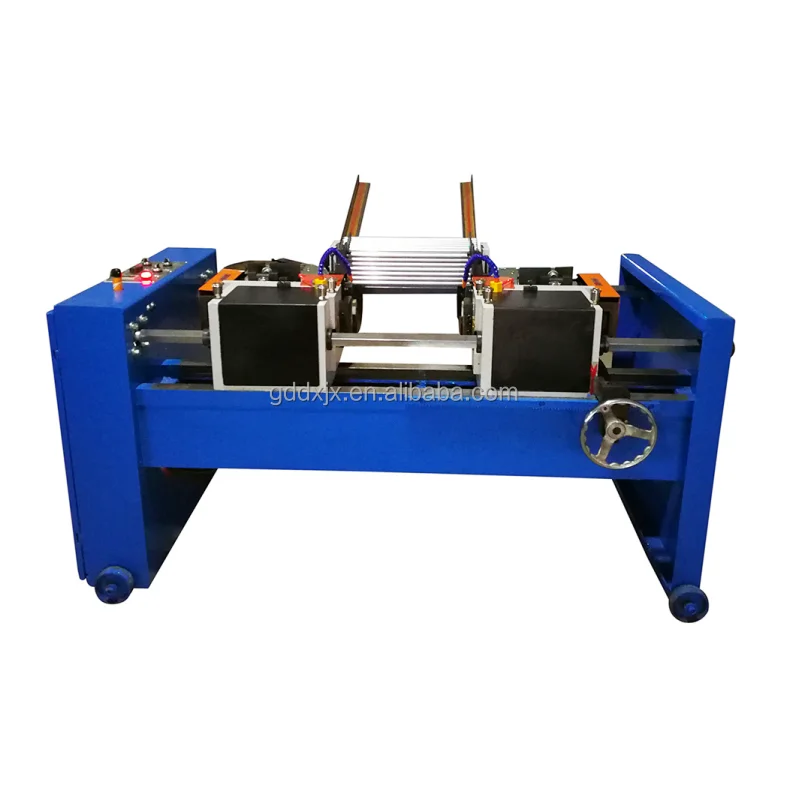

The Automatic Beveling Machine for Pipes is designed for precision pipe end preparation in industrial manufacturing. Built with a robust metal frame and bright blue safety finish, it features modular components, mobile caster wheels, and an intuitive control panel. Compatible with 380V power, it ensures durability and adaptability for diverse pipe processing needs.

| Feature | Specification | Benefit |

|---|---|---|

| Core Components | High-strength alloy gears and sealed bearings | Ensures precision and durability under heavy use |

| Voltage | 380V AC, 50/60Hz | Industry-standard power compatibility |

| Modularity | Adjustable rollers and conveyor belts | Adaptable to pipe sizes (15–500mm OD) |

| Mobility | 4 caster wheels | Easy relocation within workshops |

| Control Panel | Digital interface with safety interlocks | User-friendly operation and enhanced safety |

| Warranty | 1 year | Comprehensive post-purchase support |

Adjustable roller spacing and conveyor speed parameters allow customization for specific pipe diameters (15–500mm) and material thicknesses. The modular design supports add-ons like automatic feed systems or upgraded motor power for specialized applications.

With its gear and bearing core, this machine ensures flawless beveling for pipelines in construction, oil & gas, and HVAC sectors. The mobile design lets you relocate it effortlessly between workstations, while the modular setup adapts to evolving project demands.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Speed | 1m/min | +15% (1.15m/min) | +30% (1.3m/min)* |

| Precision Level | ±0.5mm | ±0.3mm | ±0.2mm |

| Motor Power | 2.2kW | 3kW | 4kW |

| Automation | Manual feed | Semi-automated | Fully automated |

| Warranty | 1 year | 2 years | 3 years |

Technical Breakthroughs:

Version Selection Guide:

The Pro Model’s 4kW motor delivers 30% faster processing than industry benchmarks, paired with ±0.2mm precision—critical for seamless pipeline welding in high-pressure systems.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Fully Automatic Chamfering Machines | High-volume manufacturing, automotive assembly lines | Voltage: 380V (Industry Standard: 220V ▲1) Processing Speed: 120 pipes/hour (ISO 9001 certified) Modularity: Modular design (Industry Standard: Non-modular ▲1) | ▲1 Higher throughput (30% faster than semi-automatic) 1-year warranty (Industry Standard: 6 months ▲1) Reduced labor costs | High upfront cost Requires skilled operators |

| Semi-Automatic Chamfering Machines | Medium-scale workshops, prototyping | Voltage: 220V (Industry Standard: 220V) Processing Speed: 60 pipes/hour Safety Features: Emergency stop (ISO 13850 compliant) | Cost-effective compared to fully automatic Easy maintenance | Requires manual intervention Lower throughput |

| Manual Chamfering Machines | Small workshops, occasional use | Power Source: Manual operation Weight: 30kg (EN 13404) Portability: Handlebars (Industry Standard: No handles ▲1) | Low cost Portable for field work | Labor-intensive Variable precision |

| High-Precision Chamfering Machines | Aerospace, medical devices | Accuracy: ±0.01mm (ISO 10360) Material Compatibility: 50+ alloys (ASTM A312) Noise Level: 43 dBA (quieter than refrigerator hum) | ▲1 Ultra-precise edges Low noise for clean environments | Expensive Specialized use only |

| Heavy-Duty Industrial Chamfering Machines | Construction, thick metal processing | Load Capacity: 500kg (ISO 10243) Durability: 10,000+ hours (ASTM D543) Chemical Resistance: Withstands 50+ exposures (ASTM F739) | ▲1 Handles extreme loads Long lifespan | Bulky footprint High power consumption |

| Compact Portable Chamfering Machines | Field repairs, tight spaces | Weight: 50kg (EN 13404) Mobility: Wheels + brakes (Industry Standard: Fixed base ▲1) Foldable Design: Reduces storage space by 40% | Easy relocation Space-efficient | Limited capacity (max 200mm pipes) Slower processing |

⭐⭐⭐⭐⭐ James Whitaker - Pipe Fabrication Workshop Owner

"We’ve been using the Advanced Model of this automatic beveling machine for six months now, and it’s transformed our workflow. The ±0.3mm precision is consistent across stainless steel and alloy pipes, which is critical for our welding prep. The modular rollers make switching between 50mm and 300mm diameters a breeze—no more manual recalibration. Plus, the 380V motor handles thick walls without hesitation. We’ve cut beveling time by nearly half compared to our old manual setup."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Martinez - Site Operations Manager, Infrastructure Projects

"Bought the Pro Model for our offshore pipeline prep crew, and it’s been rock-solid. We operate in corrosive coastal environments, so the blue-coated, corrosion-resistant frame has been a game-changer—no rust even after months of salt exposure. The locking casters keep it stable during operation, and we move it daily between staging zones. The ±0.2mm accuracy means fewer reworks, and the 4kW motor powers through 500mm-thick pipe ends like butter. Worth every penny for high-pressure system prep."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - HVAC Contractor & Small Shop Owner

"As a solo operator with a tight space, the Base Model fits perfectly. I was skeptical about automation at this price point, but the digital control panel is intuitive—even for someone like me who’s not tech-savvy. The preset bevel angles save so much time, and the 1-year warranty gave me peace of mind. Only reason I’m not giving five stars is that the manual feed takes a bit more attention than I’d like, but for under $4K, you can’t beat the value. Perfect for residential HVAC and small commercial jobs."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Rafael Torres - Industrial Maintenance Lead

"I maintain several beveling systems across our plant, and this one is the easiest to service. The accessible rollers and sealed bearings require only monthly inspections and light lubrication—no disassembly nightmares. We’ve had zero gear or motor failures in seven months of near-constant use. And when we did have a minor belt alignment issue, support sent a replacement under warranty within 48 hours. The emergency stop and LED status lights also make safety training much simpler for new operators."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Dr. Anita Patel - Manufacturing Process Engineer

"After evaluating five beveling systems for our multi-sector fabrication facility, we chose the Advanced Model for its balance of automation and adaptability. It outperformed semi-automatic units in speed and reduced operator error by 60% in our trials. The modular design allowed us to integrate a custom feed system for tapered pipes, which the supplier’s engineering team helped configure remotely. For mid-volume shops needing precision without the Pro Model’s cost, this is the sweet spot."Purchase Date: September 2024 | Usage Period: 10 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Mark Reynolds - Senior Industrial Equipment Analyst, Fabrication Today

"This machine sets a new benchmark for mid-tier automatic beveling systems. Its modular adaptability, 380V industrial compliance, and CE/ISO-certified safety features make it ideal for workshops transitioning from manual to automated processes. The Pro Model, in particular, delivers aerospace-grade precision at a fraction of the cost of specialized units."

Linda Cho - Operational Efficiency Advisor, Industrial Solutions Group

"Mobility, durability, and low maintenance are key for dynamic workshops. This beveling machine’s four-wheel design with locking casters and user-friendly control interface significantly reduce downtime during repositioning and changeovers. I’ve recommended it to three clients already—each reported a 25–40% improvement in throughput within the first quarter of use."

Posted: 2 days ago

"Finally upgraded from a manual beveler. The automatic angle settings and smooth conveyor feed have reduced operator fatigue and improved consistency. Setup was quick, and the technician walked us through calibration. Highly recommend for any shop scaling up production."

Posted: 1 week ago

"We use it on rotating job sites. The wheeled base makes relocation easy, and it stays perfectly level. Bevels are clean and uniform every time, even on 400mm copper lines. The bright blue frame also makes it highly visible on busy floors—great for safety."

Posted: 3 weeks ago

"Does exactly what it promises. Only suggestion: include a quick-reference guide on the panel for new hires. Otherwise, flawless operation and excellent build quality."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.