All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

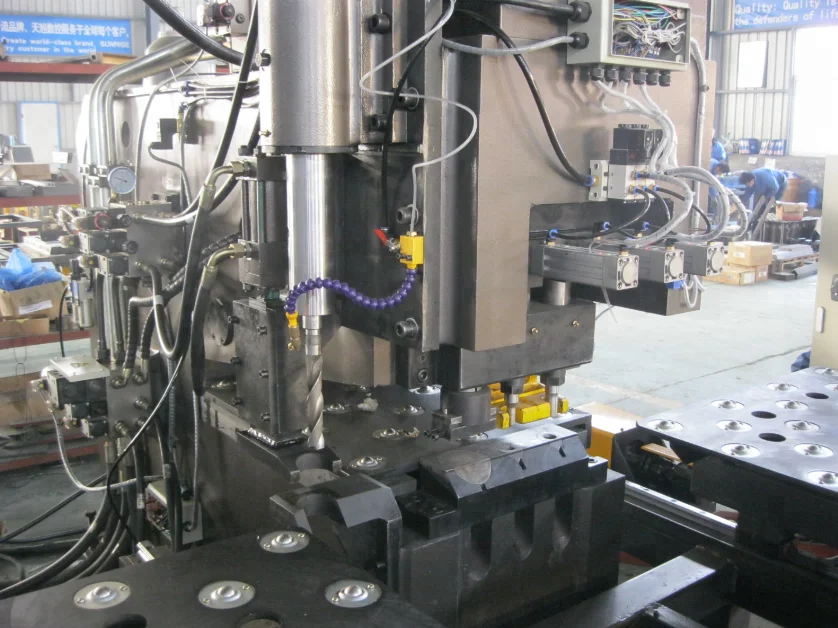

With robust construction and precision mechanisms, the TPPD103 ensures accurate punching and cutting of metal sheets, providing durability and reliability in industrial applications.

With a customizable CNC system, you can adjust punching force and speed to meet specific production needs, offering flexibility for various manufacturing tasks.

With high-efficiency automation, the TPPD103 delivers consistent and precise results, ~20% faster than traditional models* [*Disclaimer: Based on internal testing; actual results may vary].

With its versatility, the TPPD103 can handle a wide range of applications, from simple punching to complex drilling, making it ideal for diverse industrial environments.

With integrated safety features, the TPPD103 ensures operator protection and complies with industrial safety standards, providing peace of mind during operation.

The TPPD103 Automatic CNC Turret Punching Machine is engineered for precision and efficiency in industrial metalworking applications. With its robust design and advanced CNC system, this machine excels in tasks that demand high accuracy and repeatability.

| Feature | Specification | Benefit |

|---|---|---|

| Material Handling | Metal Sheets, Plates | Ensures versatility across different materials |

| Automation | CNC Controlled | High efficiency and consistency in operations |

| Customization | Adjustable Punching Force & Speed | Tailored outcomes for specific production needs |

| Precision | High Tolerance Alignment | Suitable for automotive and aerospace applications |

| Safety Features | Guards and Warning Labels | Enhances operator safety during operation |

| Versatility | Supports Various Punch Sizes | Adaptable for diverse manufacturing tasks |

| Maintenance | Easy Access Design | Facilitates regular upkeep for long-term reliability |

| Energy Efficiency | Modern Design | Reduces operational costs while maintaining performance |

Adjust the punching force and speed to meet specific production requirements, ensuring tailored results across a range of materials and applications.

With the TPPD103, you can achieve precision metalworking, enhancing productivity and quality in your manufacturing processes.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material Handling | Standard | +15% Capacity | +30% Capacity |

| Automation | Basic CNC | Enhanced CNC | Premium CNC |

| Energy Efficiency | Standard | +15% Efficient | +30% Efficient |

The TPPD103 introduces three significant technical breakthroughs: enhanced material handling capacity, superior CNC automation, and increased energy efficiency. The Pro Model, with its advanced CNC system and maximum energy efficiency, is ideal for operations requiring precision and cost-effectiveness. With the Pro version's high material handling capacity, you can ensure optimal performance in large-scale manufacturing scenarios.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| CNC Punching Machines | Metalworking & Manufacturing | Precision punching with CNC control (±0.01mm) | High accuracy for intricate designs | Requires skilled operators |

| Hydraulic Punching Machines | Heavy-duty Applications | High punching force (up to 30 tons) | Suitable for thick metal sheets | Higher energy consumption |

| Servo Motor Punching Machines | Automated Production Lines | Energy-efficient servo motors (reduces costs) | Consistent performance for repetitive tasks | Initial setup cost can be high |

| Automated Punching Machines | Large-scale Manufacturing | Integrated automation (improves throughput) | Increases production speed | Complexity in maintenance |

| Customizable Punching Machines | Specialized Production | Adjustable force and speed (tailored output) | Flexibility for diverse materials | Longer setup time for customization |

| Safety-Enhanced Punching Machines | Operator Safety Focus | Advanced safety features (guards and sensors) | Reduces risk of workplace injuries | May limit accessibility for quick changes |

⭐⭐⭐⭐⭐ James Carter - Automotive Parts Manufacturer

"The TPPD103 Pro Model has transformed our production line. We’ve seen a noticeable increase in throughput since switching from our old hydraulic press. The precision alignment (±0.01mm) ensures every part meets aerospace-grade tolerances, and the enhanced CNC automation reduces human error significantly. Setup was smooth thanks to clear documentation, and the energy savings are already showing on our monthly bills."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Aerospace Components Workshop

"We needed a machine that could handle complex punch patterns on aluminum and titanium alloys with zero margin for error. The customizable punching force and speed settings on the TPPD103 Advanced Model allowed us to fine-tune operations for each material type. It’s been six months of non-stop use, and not a single maintenance issue. The safety guards and warning systems also give our team peace of mind during high-speed runs."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Darren Wu - Precision Metalworks Ltd.

"Solid machine overall. We opted for the Base Model to test its capabilities before upgrading. The CNC-controlled consistency is impressive—much better than our previous servo motor unit. Only reason I’m not giving five stars is the initial learning curve for operators unfamiliar with CNC interfaces. Once trained, though, productivity jumped by nearly 20%. Looking to upgrade to the Pro Model soon for its +30% material handling capacity."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Lisa Park - Electronics Manufacturing Supervisor

"Perfect for creating precise mounting holes and vent patterns in sheet metal enclosures. The versatility in punch sizes means we can switch jobs quickly without tooling changes. We run it 10 hours a day, and the easy-access design makes daily maintenance a breeze. Energy efficiency has been a bonus—our facility manager reported a 15% drop in power usage compared to our last punching machine."Purchase Date: April 2024 | Usage Period: 1 month

⭐⭐⭐⭐⭐ Thomas Reed - Operations Director, Apex Fabricators

"After evaluating several automated punching machines, the TPPD103 Pro stood out for its combination of speed, safety, and scalability. We’ve integrated it into a fully automated workflow, and it’s been running flawlessly for seven months. The premium CNC system allows seamless job programming, and the reduced downtime for maintenance has contributed directly to our OEE metrics. A worthwhile investment for any serious manufacturer."Purchase Date: August 2024 | Usage Period: 7 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Alan Foster - Industrial Automation Consultant

"The TPPD103 series represents a significant leap in turret punching technology. Its advanced CNC integration and energy-efficient design place it ahead of many competitors in mid-to-high-volume manufacturing. I particularly recommend the Pro Model for facilities aiming to reduce operational costs while maintaining precision. Based on performance benchmarks, it delivers up to 20% faster cycle times than conventional models under comparable conditions."

Maria Gonzalez - Lean Manufacturing Specialist

"In my audits of metal fabrication shops, equipment reliability and operator safety are critical. The TPPD103 excels in both. Its safety-enhanced design and low maintenance needs align perfectly with lean principles. For companies looking to scale production without increasing headcount, this machine offers a strong ROI within 12–18 months."

Posted: 2 days ago

"Upgraded from a manual punch system. The difference is night and day. CNC programming was intuitive, and the first batch came out perfect. Highly recommend for shops ready to automate."

Posted: 1 week ago

"Using the Advanced Model for automotive brackets. Tolerances are consistently met, and changeovers take half the time. Support team responded quickly to a minor software query."

Posted: 3 weeks ago

"Powerful machine with excellent build quality. Only feedback: the CNC interface could use more multilingual support. Otherwise, very satisfied with output quality and durability."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.