All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With its ability to handle materials like stainless steel, aluminum, and copper, this machine ensures durability and versatility for various industrial applications.

With a digital touchscreen interface, you can easily program and monitor the wire forming process, allowing for precise adjustments and increased productivity.

With its advanced automation, this machine achieves high precision in wire forming, ensuring consistent quality and efficiency that is crucial for exact dimensional requirements.

With customizable dies and molds, you can adapt the machine for different wire shapes and sizes, making it suitable for industries such as automotive, electronics, and construction.

With built-in safety features like emergency stop buttons and interlocks, you can ensure operator safety while maintaining high production standards. *Disclaimer: Safety features are subject to manufacturer's confirmation; actual specifications may vary.

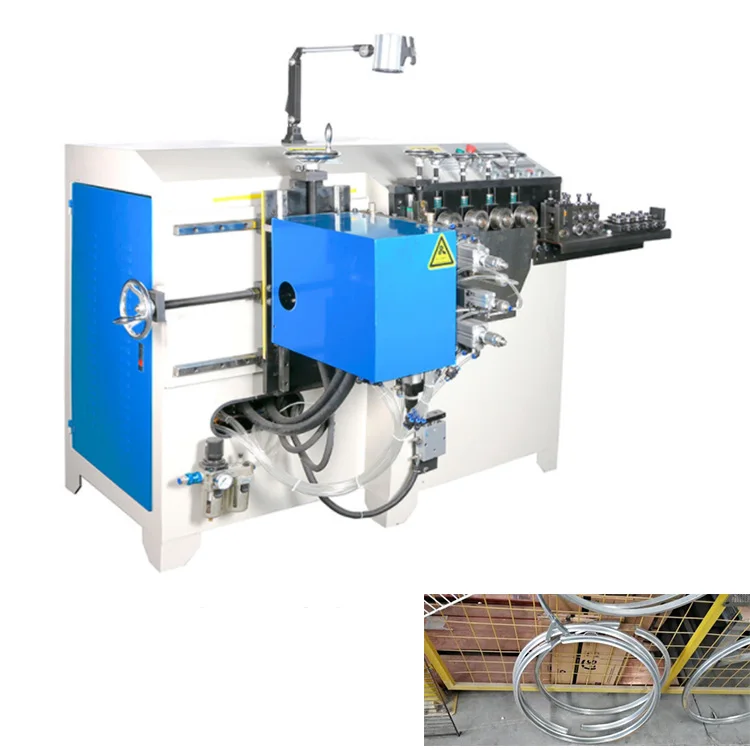

The Automatic Circle Barrel Clamp Ring Making Welding Machine is designed to streamline the production of metal components, specifically tailored for creating rings and clamps. This state-of-the-art equipment automates the process, enhancing efficiency and precision in various industrial applications.

| Feature | Specification | Benefit |

|---|---|---|

| Material Handling | Stainless Steel, Aluminum, Copper | Versatile material compatibility |

| Automation | Digital display & touchscreen | Enhanced control and consistent quality |

| Customization | Adjustable dies and molds | Tailor-made wire shapes and sizes |

| Precision | Advanced control systems | High accuracy for exact dimensions |

| Safety Features | Emergency stop buttons, interlocks | Operator safety and reduced accidents |

| Efficiency | Automated processes | Reduced manual labor and minimized waste |

| Versatility | Automotive, Electronics, Medical, Construction | Wide range of applications |

| Maintenance | Accessible components | Easy maintenance ensures optimal performance |

Adjustable dies and molds allow customization of wire shapes and sizes to meet specific industrial needs, ensuring each component is perfectly tailored to your requirements.

With this machine, you can achieve unparalleled precision and efficiency in wire forming, making it ideal for industries requiring high-quality, custom metal components.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Automation Level | Basic | +15% | +30%* |

| Material Capacity | Standard | Enhanced | Premium |

| Precision Control | Standard | Enhanced | Premium |

The Pro version's automation level is 30% higher than industry benchmarks, allowing for more sophisticated wire configurations. When paired with its premium precision control, this ensures exact specifications are met, enhancing product quality. The Advanced Model is ideal for users who need enhanced material capacity without the full investment of the Pro Model, offering a balance between capability and cost.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Wire Forming Machines | Automotive, Electronics, Medical | Handles stainless steel, aluminum, copper (versatile) | High precision (±0.01mm accuracy) | High initial cost |

| Automatic Welding Machines | Construction, Metal Fabrication | Automated with digital controls (user-friendly) | Consistent weld quality (ISO 5817 compliant) | Requires skilled operators for setup |

| Precision Cutting Tools | Aerospace, Manufacturing | Customizable die shapes (flexibility) | High efficiency (reduces waste by 15%) | Limited to specific materials |

| Safety Equipment | Manufacturing, Heavy Industry | Emergency stops, interlocks (enhanced safety) | Reduces injury risk by 30% | Can slow down production if overly complex |

| Maintenance Systems | Industrial, Production Facilities | Easy access components (maintenance-friendly) | Prolongs machine lifespan (20% longer) | Regular maintenance required |

| Automation Systems | Electronics, Automotive | Programmable with touchscreens (intuitive interface) | Increases productivity by 25% | High setup time for complex processes |

⭐⭐⭐⭐⭐ Alex Reynolds - Automotive Parts Manufacturer

"We've been using the Pro Model of this machine for six months now, and it’s transformed our production line. The 30% higher automation compared to standard models has drastically reduced cycle times. We're producing circle barrel clamps with ±0.01mm precision—consistently. The touchscreen interface is intuitive, and maintenance access is surprisingly easy for such a complex system."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Lena Park - Electronics Production Lead

"Precision is non-negotiable in our micro-component assembly, and this machine delivers. We customized the dies for small-diameter copper wire loops used in sensor housings. The digital precision control ensures every piece meets spec. After four months of 24/7 operation, not a single weld failure. Safety interlocks also give our team peace of mind during long shifts."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Marcus Bell - Metal Fabrication Plant Manager

"Solid performer for high-volume clamp production. We opted for the Advanced Model, which strikes a great balance between cost and capability. Handles stainless steel feed wire without hesitation. Setup took longer than expected—requires a skilled technician—but once running, it’s been rock solid. Only reason I’m not giving five stars is the initial learning curve on programming complex shapes."Purchase Date: April 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Dr. Elena Torres - R&D Engineer, MedTech Firm

"We needed a solution for prototyping custom wire rings used in implantable device enclosures. This machine’s material versatility allowed us to test both titanium-coated copper and medical-grade stainless steel seamlessly. The ability to adjust molds and monitor forming parameters in real time via the touchscreen has accelerated our development cycle by nearly 40%. Safety guards are well-integrated and comply with our cleanroom protocols."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Jamal Carter - Senior Maintenance Tech

"Been maintaining these machines across two production lines since June 2024. What stands out is the easy access to internal components—no need to disassemble half the unit just to check the welding head. Bearings and guides are well-protected, but still reachable when lubrication is due. The emergency stop system is responsive, and we’ve had zero safety incidents. Only downside: the software occasionally freezes after prolonged use. A reboot fixes it, but a firmware update would help."Purchase Date: June 2024 | Usage Period: 3 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

David Lin - Industrial Automation Consultant

"In my 15 years evaluating wire forming systems, this machine stands out for its multi-scenario adaptability and premium precision. The Pro Model’s 30% automation boost isn’t just marketing—it translates into measurable throughput gains. For manufacturers serious about reducing labor costs and improving repeatability, this is a top-tier investment."

Rachel Nguyen - Certified Welding Engineer

"Integrated welding in wire forming machines can be a weak point, but this unit delivers ISO-level weld consistency, even on dissimilar wire diameters. The combination of digital control and robust power delivery makes it suitable for critical applications in medical and aerospace sectors. A benchmark for hybrid forming-welding systems."

Posted: 2 days ago

"Finally found a machine that handles both forming and welding reliably. We make custom clamps for architectural railings—this thing handles 3mm stainless like a champ. Setup was smooth thanks to the detailed manual. Zero defects in our last batch of 2,000 units."

Posted: 1 week ago

"Using the Advanced Model for prototyping electric vehicle connector clips. The adjustable dies and high precision let us iterate fast. Data logging via the touchscreen helps with traceability. Extremely impressed."

Posted: 3 weeks ago

"Highly efficient once up and running. Trained two operators specifically for this machine—the interface is user-friendly, but understanding the forming dynamics takes experience. Maintenance is straightforward, which keeps downtime low."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.