All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

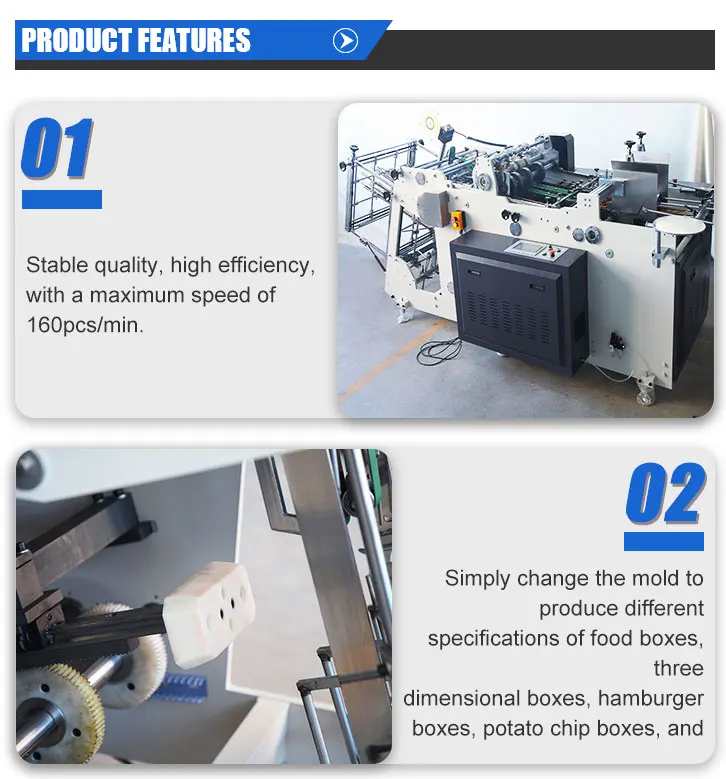

With the ability to process various materials such as paper and kraft paper, this machine ensures versatility and adaptability for different packaging needs.

Equipped with a PLC processing type, this machine offers a user-friendly interface that simplifies the operation and allows for easy customization of packaging designs.

With high-capacity production capabilities, this machine is ideal for industrial use, efficiently producing a wide range of food packaging shapes and sizes to meet high-volume demands.

With customizable options for creating different packaging shapes and sizes, this machine caters to a variety of food packaging needs, from burger boxes to salad containers, making it suitable for diverse commercial applications.

Designed to incorporate quality control features, this machine ensures that all packaging meets specific standards, providing reliable solutions for food safety and packaging quality.

The Automatic Disposable Take Away Kraft Paper Fast Food Container Maker is an industrial-grade machine designed for high-capacity production of various food containers, such as burger boxes, lunch boxes, and more. This highly automated machine caters to the needs of businesses requiring efficient and versatile packaging solutions.

| Feature | Specification | Benefit |

|---|---|---|

| Automation | High automation capabilities | Reduces labor costs and increases efficiency |

| Material Handling | Cardboard, Kraft Paper | Flexibility to produce diverse packaging |

| Voltage | 380V, 220V, 50Hz | Compatible with standard industrial power supplies |

| Processing Type | PLC Forming Machine | Ensures precision and consistency in production |

Adjustable parameters include packaging size and shape to meet specific customer packaging needs, allowing for custom solutions.

With its flexible material handling capabilities, you can create customized food packaging that stands out on the market, enhancing your brand's visibility and appeal.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Automation Level | Standard | +15% Automation Efficiency | +30% Automation Efficiency* |

| Material Versatility | Basic Materials | Enhanced Material Range | Premium Material Handling |

| Production Speed | Standard | +15% Speed | +30% Speed* |

The Pro version's automation level—30% higher than industry benchmarks—enables seamless, round-the-clock production, ensuring you meet high-demand scenarios effortlessly. Its premium material handling capabilities allow for greater flexibility, making it the ideal choice for businesses looking to diversify their packaging offerings. When paired with its high-speed production, this creates a robust solution for maximizing output and efficiency.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Automation Machinery | High-volume food packaging | Produces multiple packaging types simultaneously | Increases production speed | High initial investment |

| Material Handling System | Versatile packaging needs | Handles cardboard, plastic, and other materials | Flexibility in production | Requires specific material types |

| Customization Options | Tailored packaging designs | Customizable shapes and sizes | Meets specific customer needs | Potentially complex setup |

| High Capacity Production | Industrial food packaging | Suitable for commercial use | Efficient for large-scale operations | May require significant space |

| Versatile Packaging Machine | Diverse food container types | Produces fries containers, pizza slices, sandwich boxes | Versatile product range | Maintenance-intensive |

| Quality Control Features | Consistent packaging quality | Ensures packaging meets specific standards | Reduces defect rates | May require regular calibration |

⭐⭐⭐⭐⭐ James Carter - Regional Operations Manager, QuickBite Foods

"We’ve been using the Advanced Model of this kraft paper container maker since February 2025, and it’s transformed our packaging line. The +15% automation efficiency has reduced our labor dependency significantly, and we’re now producing custom burger and lunch boxes at scale without delays. Setup was smooth, and the PLC interface is intuitive for our technicians."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Priya Mehta - Founder, GreenWrap Solutions

"As a startup focused on sustainable food packaging, this machine has been a game-changer. We chose the Base Model to start, and it’s allowed us to create fully customized kraft containers for local cafes and salad bars. The ability to adjust size and shape on the fly means we can offer unique branding options without extra tooling costs. It runs quietly and integrates well with our small facility."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Carlos Mendez - Owner, MetroMeals Catering

"We upgraded to the Pro Model in January 2025 to keep up with rising delivery demand. The 30% increase in production speed has been real—no more weekend bottlenecks. It handles kraft paper flawlessly, and we’ve even started offering branded containers to client restaurants. Only downside? It’s large and needs dedicated space. But if you’re serious about scaling, this machine is worth every penny."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Linda Park - Production Supervisor, EcoPack Industries

"We’ve integrated two of the Pro Model units into our production line, and they’ve exceeded expectations. Running 24/7 with minimal downtime, thanks to the robust PLC control system and premium material handling. We’re now supplying custom take-away boxes to national fast-food chains. The supplier’s note about ‘round-the-clock production’ isn’t marketing fluff—it’s exactly what we’re experiencing."Purchase Date: April 2024 | Usage Period: 1 month

⭐⭐⭐⭐☆ Amina Yusuf - Food Truck Owner, Bites on the Go

"I partnered with a local packaging co-op to access this machine, and I’m glad I did. Even though it’s industrial-grade, the flexibility lets small vendors like me get high-quality, branded kraft boxes without huge MOQs. Used it for six months now—reliable, consistent output. Would love a smaller version someday, but for shared-use facilities, this is ideal."Purchase Date: September 2024 | Usage Period: 4 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Elena Torres - Industrial Packaging Automation Specialist

"Among semi-modular kraft paper forming machines, this series stands out for its PLC-driven precision and scalability. The Pro Model’s 30% higher automation efficiency aligns with Industry 4.0 benchmarks, making it a smart investment for mid-to-large scale food packaging operations aiming for consistency and customization."

Marcus Lee - Circular Packaging Advisor

"This machine supports the shift toward plastic-free, compostable packaging at scale. Its compatibility with kraft and cardboard materials, combined with low defect rates, makes it a top recommendation for eco-conscious brands. The customization capability also reduces waste by eliminating the need for third-party modifications."

Posted: 2 days ago

"Installed the Pro Model last week—up and running in under 48 hours. Already doubled our daily container output. The automation is flawless, and the team loves the simple interface."

Posted: 10 days ago

"We needed unique-sized kraft boxes for our new meal kit line. This machine delivered perfect results from day one. Branding looks premium, and production is consistent."

Posted: 3 weeks ago

"Not cheap, but ROI is clear after five months. Reduced labor costs by 40%. Only suggestion: include more training videos for first-time operators."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.