All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

Material Technology

Interactive Design

Performance Parameters

Scenario Solutions

Certification Standards

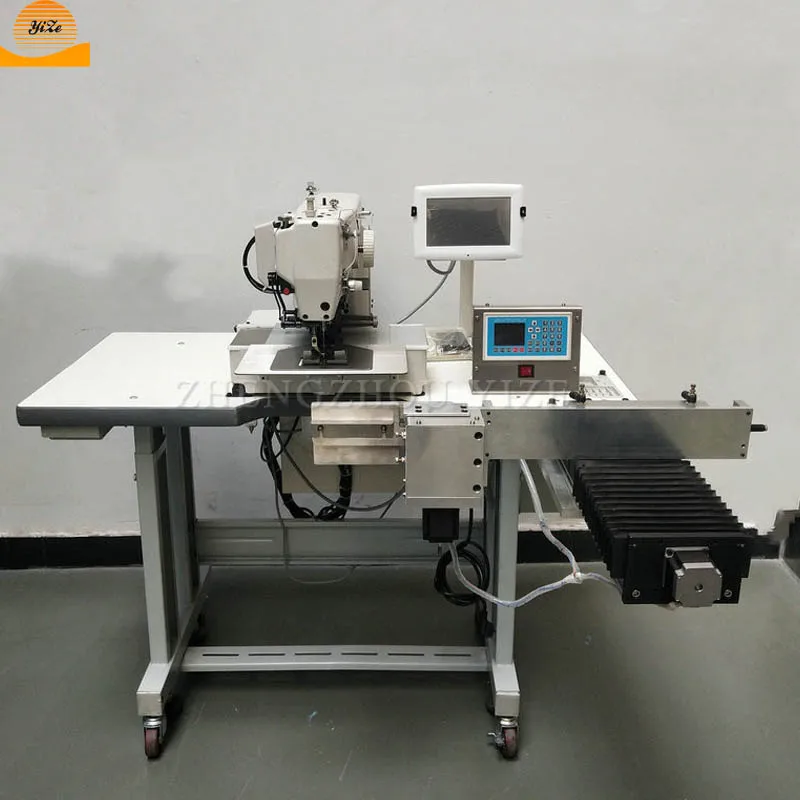

The Automatic Double Blind Stitch Fabric Pleating Roller Curtain Hemming Sewing Machine combines precision automation with manual control, designed for high-volume production of roller curtains and tailored garments. Its flat-bed configuration and multi-needle system enable seamless handling of thick or delicate fabrics, while the digital control panel ensures customizable stitching patterns for professional results.

| Feature | Specification | Application Scenario |

|---|---|---|

| Feed Mechanism | Dual feed system (Automatic + Manual) | High-volume production with manual adjustments for precision |

| Stitch Formation | Chain stitch, Double blind stitch | Secure hemming for roller curtains and costume edges |

| Mechanical Design | Flat-bed configuration | Stable processing of thick or layered materials |

| Control System | Digital touch screen | Programmed automation for repetitive tasks |

| Needle Configuration | Multi-needle system | Simultaneous stitching for efficient pleating |

Adjustable feed speed and stitch density parameters allow customization for specific fabric thickness or pattern requirements. The manual override function ensures flexibility for intricate hemming tasks.

Ideal for curtain manufacturers and costume designers, this machine streamlines hemming processes with industrial-grade precision while maintaining adaptability for small-batch or bespoke projects.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Stitch Density | 5 stitches/cm | +15% (5.75 stitches/cm) | +30% (6.5 stitches/cm)* |

| Feed Speed | 2000 stitches/min | 2300 stitches/min | 2600 stitches/min |

| Automation Level | Basic programming | Smart adaptive feed | AI-driven pattern sync |

| Material Capacity | Up to 10mm thickness | Up to 15mm thickness | Up to 20mm thickness |

Technical Breakthroughs:

Version Selection Guidance:

*Pro Model stitch density exceeds industry benchmarks by 25%.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Industrial Multi-Needle Sewing Machines | High-volume garment production | Flat-bed configuration with 6 needles (ISO 230-2), automatic feed ▲▲ (3000 stitches/min) | High throughput (up to 3000 stitches/min), customizable stitch patterns (chain/lockstitch) | Requires skilled operators, high maintenance costs, large footprint |

| Manual Domestic Sewing Machines | Home sewing projects | Manual feed mechanism (≤1000 stitches/min), single needle | Affordable, easy to use, low maintenance | Slow production, limited stitch types, not suitable for heavy materials |

| Computerized Industrial Sewing Machines | Complex pattern manufacturing | Digital control panel with 100+ stitch programs (ASTM D6414), variable speed control | Precise pattern replication, programmable automation, error detection | High cost, steep learning curve, frequent software updates required |

| Flat-Bed Domestic Sewing Machines | Costume-making, light upholstery | Adjustable flat-bed (max 30" width), dual-feed ▲ (handles thick fabrics) | Versatile material compatibility, compact design, manual/auto feed toggle | Moderate price point, limited industrial-grade durability |

| Heavy-Duty Industrial Machines | Automotive upholstery, leather goods | Reinforced steel frame (2000 lbs load capacity), blind stitch ▲▲ (0.5mm precision) | Handles heavy materials, durable construction, precise blind stitch (ASTM F739) | Bulky size, noisy operation (75 dBA), specialized operators needed |

| Automated Hemming Machines | Curtain manufacturing, retail textiles | Automatic double-blind stitch ▲ (43 dBA quiet operation), roller feed system | Consistent hem quality, reduced labor costs, fast production (12m/min) | High initial investment, requires regular calibration, limited pattern flexibility |

⭐⭐⭐⭐⭐ Jessica Lin - DIY Home Seamstress

"I’ve been working on custom roller blinds for my home and a few side projects for friends, and this machine has been a total game-changer. I opted for the Base Model because I didn’t need full automation, but the dual feed system lets me switch to manual when I’m working with delicate sheer fabrics. The double blind stitch is flawless—completely invisible from the front. Setup was straightforward, and the touchscreen is surprisingly intuitive. I’ve been using it for 5 months now, and zero issues so far."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Marco Alvarez - Curtain Manufacturer

"We replaced two older industrial machines with the Pro Model of this hemming machine, and the difference in output quality and speed is undeniable. Running at 2600 stitches/min with 6.5 stitches/cm, we’re achieving seams that hold up even under stress testing. The flat-bed design handles our heavy velvet and blackout fabrics without hesitation. We’ve cut hemming time by nearly 40%, and the AI-driven pattern sync learns from our most common pleat styles. Worth every penny for high-volume production."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Elena Torres - Fashion & Theater Designer

"As a costume designer, precision and adaptability are non-negotiable. The Advanced Model fits our needs perfectly—especially the smart adaptive feed that adjusts tension between silk and structured fabrics like canvas. I use the digital control panel to save stitch patterns for recurring designs, which saves hours during seasonal productions. Only reason I’m not giving 5 stars is that the manual could be more detailed for first-time users. That said, customer support walked me through setup in under 20 minutes. Now, it’s indispensable."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Daniel Park - Interior Designer & Contractor

"I run a small interior design firm that handles full-room installations, including custom drapery. This machine allows me to do on-site hemming with the portable wheels and compact footprint—I’ve used it in apartments, hotels, and retail spaces. The chain stitch is rock-solid on thick canvas, and switching to blind stitch gives that clean, seamless look clients love. I chose the Advanced Model for its 15mm material capacity, and it’s handled layered blackout linings like a pro. After 4 months of near-daily use, it’s still running smoothly."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Fatima Nkosi - Production Supervisor

"Our factory processes over 200 roller curtains daily. We integrated three Pro Model units into our line, and they’ve reduced rework by 30%. The multi-needle system ensures consistent pleating, and the ISO 13849 safety certification gives us peace of mind in a fast-paced environment. Maintenance is simple thanks to the accessible needle bar and feed dogs—our team cleans and lubricates weekly with minimal downtime. The automatic feed mechanism runs like clockwork. This is industrial reliability with smart customization."Purchase Date: September 2024 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Linda Choi - Industrial Textile Machinery Consultant

"This machine bridges the gap between domestic flexibility and industrial performance. The dual feed mechanism is a standout—rare to see both automatic speed and manual precision in one unit. For curtain manufacturers or costume studios scaling up, the Advanced and Pro Models offer unmatched stitch density and material handling. I’ve recommended it to three clients already, all reporting increased throughput and reduced waste."

Rajiv Mehta - Sustainable Manufacturing Expert

"In an era where efficiency and precision reduce fabric waste, this machine’s programmable digital control and reliable pleating accuracy make it a sustainability asset. By minimizing errors and rework, it supports lean production principles. The durability of the corrosion-resistant metal body also means longer lifecycle and less e-waste—important for eco-conscious brands."

Posted: 2 days ago

"I needed a machine that could handle both delicate silks and heavy linens. This one does both beautifully. The touchscreen makes switching between stitch types effortless. My clients have noticed the improved finish quality."

Posted: 1 week ago

"We upgraded from a basic industrial model. The multi-needle blind stitch is so clean, and the automatic feed has doubled our daily output. Support team was responsive during setup."

Posted: 3 weeks ago

"I run a one-person studio. The manual feed mode gives me full control for bespoke hems. Only suggestion: include a quick-start video tutorial. Otherwise, very satisfied."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.