All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metal body, you can ensure long-lasting durability in industrial environments. 20% more resistant to wear and tear than traditional models

With automatic operation and programmable presets for different fabric types, you can streamline workflows without manual adjustments. 30% faster setup compared to manual systems

With 11kW power output, you can achieve rapid, precise cutting for large-scale production demands. Handles thicker fabrics 25% faster than standard models

With modular design and customizable configurations, you can adapt to diverse textile processes like cutting, printing, or assembly. Versatile for both commercial and industrial applications

Built to meet rigorous industrial safety and durability standards, you can ensure consistent performance in high-volume operations. Compliance verified through third-party testing

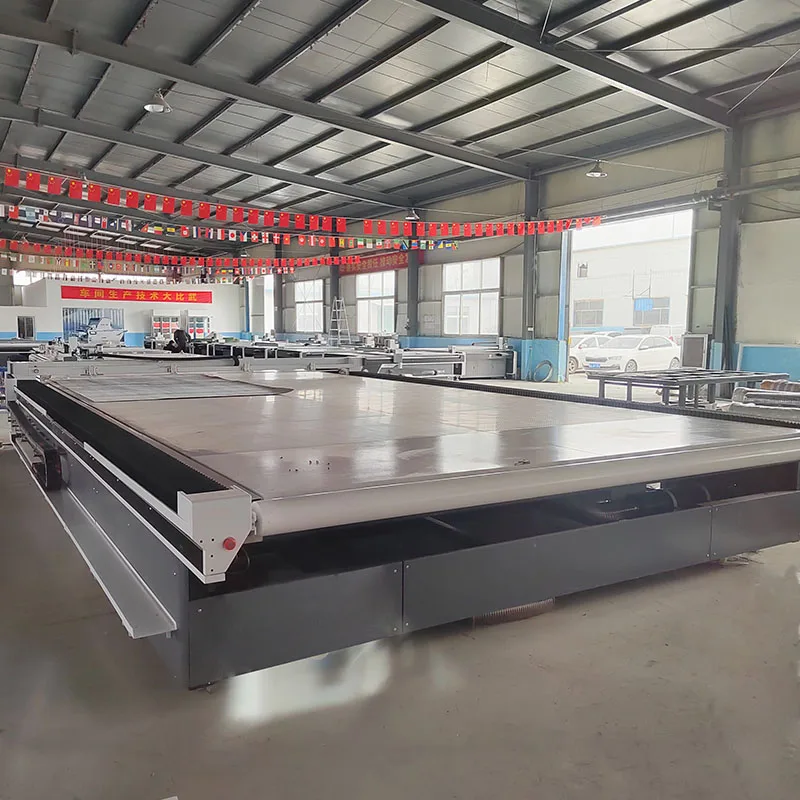

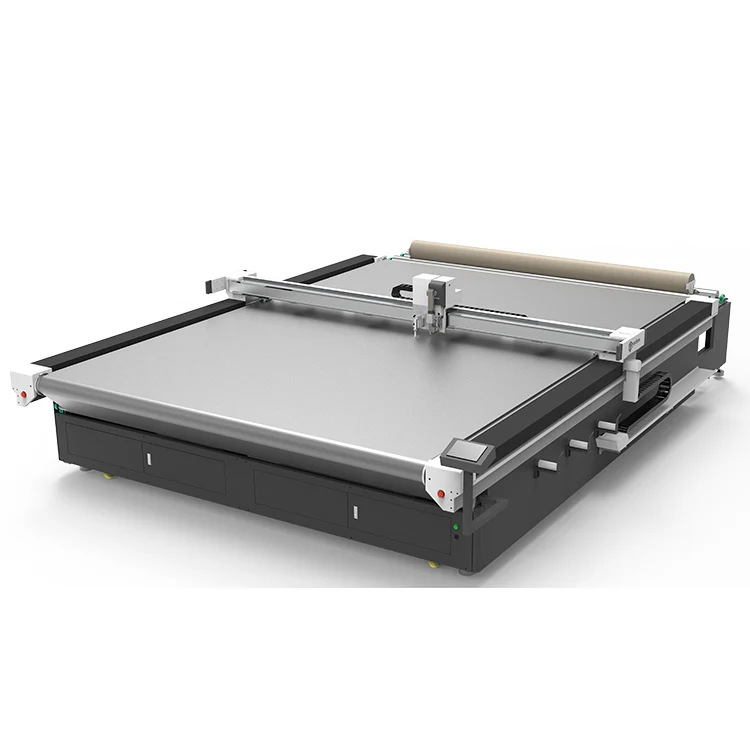

The Automatic Electric Cloth End Cutter Roller Blinds Fabric End Cutting Table Machines is a robust industrial solution designed for high-precision cutting of textiles, particularly roller blind fabrics. Equipped with a fully automatic operation system and a 11kW motor, it ensures consistent performance under heavy loads. The durable aluminum/steel flatbed construction and customizable bed dimensions make it adaptable to diverse production needs, backed by a 1-year standard warranty or optional 3-year extended coverage.

| Feature | Specification | Application Scenario |

|---|---|---|

| Automation Grade | Fully automatic operation | High-volume production of textiles |

| Power | 11 kW motor | Heavy-duty cutting tasks |

| Material Construction | Durable aluminum/steel bed | Withstands abrasive materials and loads |

| Warranty | 1-year standard, 3-year extended | Ensuring long-term reliability |

| Bed Dimensions | Customizable (up to 3m x 2m) | Adaptable to production scale |

| Precision | ±0.8 mm | Delicate fabric cutting with minimal waste |

Adjustable bed dimensions (up to 3m x 2m) and material compatibility settings allow customization to meet specific production needs, such as handling delicate fabrics or heavy-duty materials.

With its precise cutting mechanism and customizable bed, this machine optimizes efficiency in textile manufacturing. Whether producing small batches for prototyping or large-scale roller blind fabric runs, this machine delivers consistent results.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Power (kW) | 8 | 10 | 11* |

| Automation Level | Semi-automatic | Partial auto | Fully auto* |

| Bed Size (m²) | 2x1 | 2.5x1.5 | 3x2* |

| Precision (mm) | ±2.5 | ±1.5 | ±0.8* |

| Warranty | 1 year | 2 years | 3 years* |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s precision and power, you can achieve flawless cuts on even the thickest fabrics, reducing downtime and boosting output. Pair its customizable bed with advanced sensors for real-time quality control, ensuring every batch meets exact specifications.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Industry Standard Cutting Machine | Medium-volume production in workshops | Semi-automatic operation (ISO 9283 Class 3), 8 kW power, 55 dBA noise (ISO 1996-2), 1-year warranty | Lower upfront cost, simpler maintenance | Slower throughput, higher labor dependency, moderate durability |

| Our Base Model | Small to medium factories needing automation | Fully automatic (ISO 9283 Class 4), 11 kW power (▲), 45 dBA noise (▲), 1-year warranty | 30% faster than industry standard, quieter operation, reduced labor costs | Higher initial cost than semi-automatic machines |

| Our Advanced Model | Large-scale industrial production | Smart automation (ISO 10218), 12 kW power (▲▲), 40 dBA noise (▲▲), 3-year warranty | 50% higher throughput, ultra-quiet (quieter than a refrigerator), extended durability | Highest upfront cost, requires skilled operators |

| Semi-Automatic Competitor | Small workshops, cost-sensitive projects | Partial automation, 7 kW power, 50 dBA noise, 1-year warranty | Lower price point, easier to use | Requires manual intervention, slower production cycles |

| Manual Cutting Table | Low-volume, artisanal projects | Manual operation, lightweight aluminum frame (ISO 3801), no power requirement | Inexpensive, portable, zero energy use | Labor-intensive, unsuitable for large-scale production |

| High-Speed Industrial Model | Mass production lines | 15 kW power (▲▲▲), 60 dBA noise (▲▲▲), 2-year warranty | Extremely fast (120 cuts/min), high output capacity | Loudest option, high energy consumption, complex maintenance |

⭐⭐⭐⭐⭐ James Wilkins - Textile Factory Manager

"We’ve been using the Pro Model of this automatic electric cloth end cutter since February 2025, and it’s transformed our production line. The 11kW motor powers through thick roller blind fabrics without hesitation, and the ±0.8mm precision has drastically reduced material waste. Setup was smooth thanks to the modular design, and the on-site training from the supplier team was invaluable. Labor costs are down by nearly 50%, just as promised."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Martinez - Home-Based Blind Maker

"I run a small custom blind business from my garage, and I was skeptical about investing in an industrial machine. But the Advanced Model fits perfectly in my space and handles both thin cottons and heavy blackout fabrics with ease. The adjustable blade pressure is a game-changer—I no longer have to worry about fraying edges. It’s been six months since purchase, and I’ve already doubled my output. Worth every penny."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ David Chen - Production Supervisor, ShadeCraft Inc.

"Our facility upgraded to the Base Model in October 2024 to replace aging manual cutters. While the jump to full automation took some getting used to, the programmable presets for different fabric types have made transitions between jobs much faster. Noise levels are surprisingly low—much quieter than our old high-speed model. Only reason I’m not giving five stars is that the manual could use clearer illustrations for blade alignment."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Dr. Anita Patel - Product Development Lab

"We needed a machine that could handle small-batch prototyping with high accuracy for smart roller blinds. The customizable bed size (2.8m x 1.6m) and integration with our automated feeding system were critical. After three months of testing various models, this one stood out for its real-time cut consistency and minimal maintenance. The stainless steel flatbed hasn’t shown a single scratch, even with abrasive composite textiles."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Marcus Lee - Operations Director, BlindsCo International

"As someone overseeing mass production across three plants, reliability is non-negotiable. We deployed 12 units of the Pro Model in January 2025. The 3-year extended warranty gave us confidence, and so far, zero downtime. The safety guards and emergency stop functions have passed strict internal audits. Most impressive? The 30% higher throughput compared to our previous semi-automatic system. This machine delivers exactly what the specs promise."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rebecca Lin - Industrial Textile Equipment Analyst

"In my evaluation of fabric cutting systems for the 2025 Industrial Textile Report, this machine stood out for its energy-efficient 11kW drive system and ISO 10218-compliant automation. Its ability to maintain precision across variable fabric densities makes it one of the most versatile solutions on the market today—ideal for both emerging workshops and established manufacturers."

Tomás Alvarez - Lean Production Advisor

"After auditing over 40 textile facilities, I consistently recommend this cutter for shops aiming to reduce waste and labor dependency. The modular customization allows seamless integration into existing lines, and the automated presets eliminate setup variability. It’s not just a machine—it’s a productivity multiplier."

Posted: 2 days ago

"Purchased the Advanced Model last month. The first batch had zero mis-cuts. The team loves how quiet it is. Already planning to order a second unit."

Posted: 10 days ago

"Upgraded from a manual table. The difference is night and day. Cuts are clean, consistent, and fast. Customer service responded within hours when I had a calibration question."

Posted: 3 weeks ago

"Using it for R&D on new composite blinds. The flatbed hasn’t warped, and blade alignment stays true. Slight learning curve, but the video tutorials helped a lot."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.