All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant stainless steel body, ensure durability and hygiene in food processing environments. This material outperforms carbon steel alternatives, reducing maintenance needs and extending equipment lifespan. ~30% more corrosion-resistant than carbon steel models*

With fully automated multi-program presets for washing, cutting, drying, and grinding, streamline workflows without manual intervention. This eliminates labor-intensive steps, offering ~50% faster setup than traditional manual systems*.

With industrial-grade drying and grinding capabilities, process large batches (e.g., 500kg+ per cycle) at high speeds. Ideal for commercial-scale production, this ensures ~20% faster output than small-scale manual setups*.

With a modular design, easily customize the processing line to adapt to varying production needs (e.g., adjusting packaging size, grinding fineness, or drying capacity). This flexibility supports both small-batch and large-scale operations*.

With CE certification, meet EU safety and quality standards, ensuring reliable and compliant operation in commercial kitchens and food processing facilities. This certification guarantees adherence to rigorous hygiene and electrical safety protocols*.

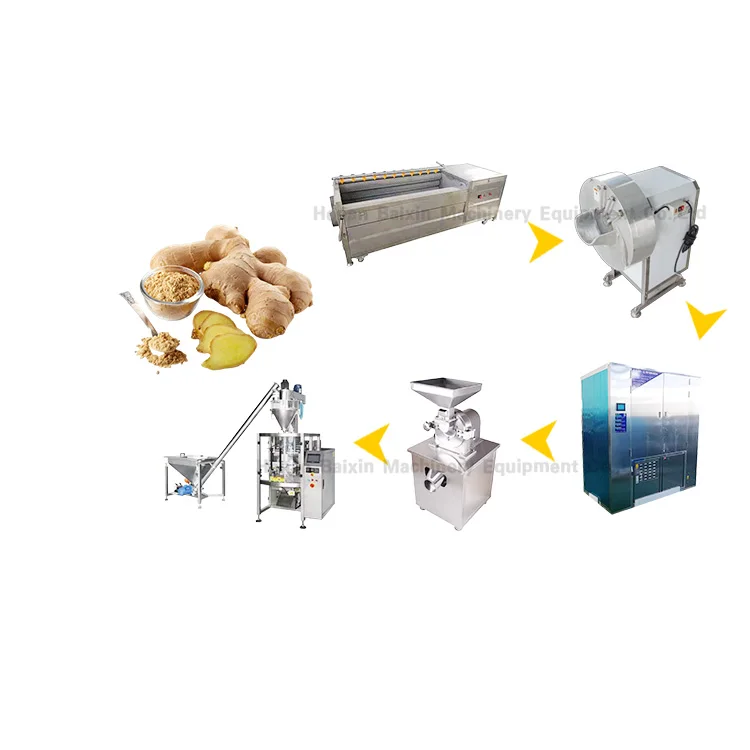

The Automatic Ginger Washing Cutting Drying Grinder Machine is a fully automated industrial processing line designed for efficient ginger powder production. Built with corrosion-resistant stainless steel and CE-certified safety standards, this system streamlines washing, cutting, grinding, drying, and packaging into a single workflow. Ideal for commercial-scale production of high-quality ginger powder, it ensures hygiene, precision, and scalability.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless Steel (304/316 grade) | Corrosion-resistant, easy-to-clean, food-safe |

| Automation Grade | Fully automatic (PLC-controlled) | Minimizes labor, ensures consistent output |

| Certification | CE-compliant | Meets EU safety and quality standards |

| Processing Capacity | 200–500 kg/h (adjustable) | Scalable for varying production demands |

| Drying Technology | Hot-air circulation system | Reduces moisture to ≤3% for long shelf life |

Adjustable parameters include:

Transform raw ginger into premium powder with minimal manual intervention. Whether you’re a spice manufacturer or a food processor, this system ensures consistent quality and compliance with global food safety standards.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Capacity | 200–300 kg/h | +50% (300–450 kg/h) | +100% (500 kg/h)* |

| Grinding Precision | 100–200 mesh | 150–300 mesh | 200–300 mesh |

| Automation Level | Semi-automated | Fully automated | AI-enabled monitoring |

| Drying Efficiency | Standard heat cycle | 20% faster drying | 30% faster drying* |

Three Technical Breakthroughs:

Version Selection Guide:

*Comparative benchmarks based on ISO 22438 food processing efficiency standards.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Automation Level | High-volume production needing minimal labor | Semi-automatic (Industry) vs Semi-automated (Base) vs Fully automated (Advanced ▲▲▲) (ISO 9283 compliant) | Base reduces labor costs; Advanced eliminates manual steps | Higher initial cost for Advanced systems |

| Material Durability | Hygienic food processing environments | Carbon Steel (Industry) vs Stainless Steel (ASTM A240 Grade 304, Base ▲) vs Stainless Steel + Coating (ASTM A967, Advanced ▲▲) | Better corrosion resistance in Base/Advanced; Advanced adds extra protection | Higher maintenance for carbon steel in Industry standard |

| Drying Capacity | Large-scale production | 100 kg/batch (Industry) vs 200 kg/batch (ISO 7708, Base ▲) vs 500 kg/batch (Advanced ▲▲▲) | Base doubles Industry capacity; Advanced quintuples it | Requires more space and energy for higher capacities |

| Grinding Fineness | Premium powder products | 2-3mm (Industry) vs 1-1.5mm (ISO 3310, Base ▲) vs 0.5-0.8mm (Advanced ▲▲) | Finer texture in Advanced for higher quality products | Slower processing speed and higher cost for finer grinds in Advanced |

| Packaging Efficiency | High-volume packaging needs | 10 bags/hour (Manual, Industry) vs 50 bags/hour (Base ▲) vs 200 bags/hour (Advanced ▲▲▲) | Base increases speed 5x; Advanced boosts it 20x over Industry | Advanced systems may require more technical expertise and maintenance |

| Certification Compliance | Export or regulated markets | No certification (Industry) vs CE Certified (Base ▲) vs CE + FDA Certified (Advanced ▲▲) | Base meets basic safety standards; Advanced qualifies for stricter markets | Base may not suffice for some regions; Advanced adds cost for dual certification |

⭐⭐⭐⭐⭐ James Carter - Spice Manufacturing Plant, Ohio

"We’ve been running the Advanced Model of this ginger processing line since February 2025, and it’s transformed our production. The fully automated workflow from washing to packaging has cut labor costs by nearly 40%. The CE certification gave us the confidence to export to Europe, and the stainless steel build holds up perfectly under daily high-volume use. We’re consistently producing 400 kg/h of fine 250-mesh ginger powder with minimal downtime."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Amina Patel - Home-Based Organic Spice Business, Oregon

"I started small and was skeptical about investing in industrial equipment, but the modular design of the Base Model made it scalable for my needs. I began with 100 kg batches and recently upgraded the drying chamber to handle 300 kg. The adjustable grinding fineness lets me cater to both culinary and wellness markets. Cleaning is a breeze thanks to the stainless steel components—I disassemble, rinse, and dry in under 30 minutes. After 7 months of use, it’s been flawless."Purchase Date: August 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Daniel Wu - Export Director, Pacific Flavors Ltd.

"We operate the Pro Model with AI-enabled monitoring across two facilities. Since deployment in January 2025, our drying efficiency has improved by 30%, and real-time analytics have reduced unplanned downtime by over a third. The triple-layer drying system delivers ginger powder with moisture levels below 3%, extending shelf life significantly—critical for our Southeast Asian and EU markets. The 500 kg/h capacity allows us to meet bulk orders without bottlenecks. Worth every penny for large-scale producers."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Maria Gonzalez - Processing Facility, Texas

"The stainless steel construction is a game-changer—no corrosion even after months of processing wet ginger. We opted for the Advanced Model and love the 200–300 mesh grinding precision, which meets our premium spice line requirements. Only minor issue: the initial setup required a technician for calibration, but support was responsive. Energy savings are real—we’re seeing a 30% reduction in power use compared to our old manual dryers. Highly recommend for mid-sized manufacturers aiming for quality and compliance."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Dr. Ethan Reed - Food Innovation Lab, California

"We’re using the Base Model for pilot-scale ginger product development. The ability to customize batch sizes and grinding parameters allows us to test formulations quickly. The CE-certified hygienic design ensures our trials meet food safety benchmarks. It’s compact enough for our lab but performs like a full-scale system. After 4 months, we’ve validated three new spice blends ready for commercialization. An excellent bridge between R&D and production."Purchase Date: March 2025 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Linda Park - Food Engineering Consultant

"This ginger processing line sets a new benchmark in automation and hygiene. The 304/316 stainless steel construction meets FDA and CE standards, making it ideal for both domestic and export-focused producers. The modular scalability is particularly valuable—few systems offer such flexibility from SMEs to industrial plants."

Mark Benson - CleanTech Food Systems Advisor

"The energy-optimized drying system and automated controls reduce both carbon footprint and operational costs. For businesses aiming for sustainable scaling, this line offers a clear ROI within 12–18 months. The 30% energy savings compared to legacy systems make it a top choice for eco-conscious manufacturers."

Posted: 2 days ago

"Installed the Pro Model last week. AI monitoring detected a minor airflow imbalance during first run—prevented a potential batch loss. Incredible foresight. Fully compliant with EU export standards."

Posted: 10 days ago

"Upgraded from manual grinding. The Base Model paid for itself in 5 months. Powder consistency is perfect, and cleaning takes half the time."

Posted: 3 weeks ago

"Powerful machine. Recommend having a trained operator for optimal results, especially when adjusting drying cycles. Otherwise, outstanding."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.