All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With corrosion-resistant stainless steel construction, ensure hygienic processing and durability in industrial environments*. Outlasting traditional models prone to corrosion, this material maintains structural integrity even in high-moisture tropical fruit processing.

With automated touchscreen controls, streamline operations and reduce labor costs compared to manual systems*. Preset programs for mango puree, juicing, and sterilization simplify workflows, offering up to 40% faster setup than non-automated alternatives*.

With customizable power output, achieve optimal performance for varying production scales, outperforming fixed-power systems*. Adjust energy consumption to match batch sizes, ensuring efficiency for both small-scale trials and large commercial runs*.

With multi-fruit versatility, process mangoes, pineapples, and other tropical fruits efficiently, expanding operational flexibility beyond single-fruit systems*. The seed-removing and sterilization features adapt to diverse fruit textures, minimizing waste and downtime*.

With food-grade and eco-friendly certifications, meet stringent safety and sustainability standards, surpassing non-certified alternatives*. Stainless steel construction and hygienic design align with global food safety regulations while reducing environmental impact*.

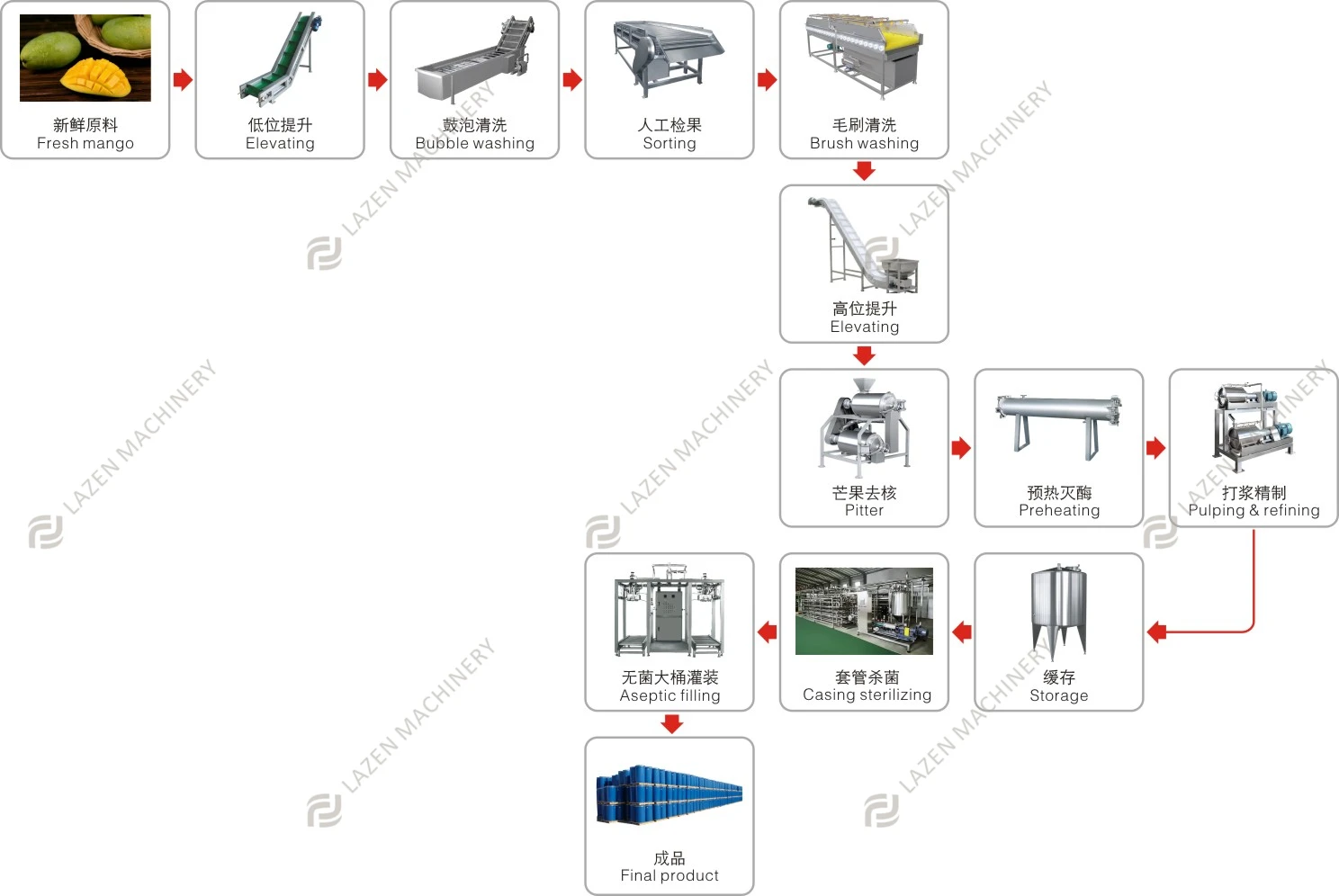

The Automatic Mango Puree Processing Line is an industrial-grade solution for high-volume mango juicing, pureeing, and seed removal. Built with corrosion-resistant stainless steel and customizable power systems, it ensures hygiene, durability, and scalability for tropical fruit processing.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless steel (304/316 grade) | Corrosion resistance, easy cleaning, food-grade safety. |

| Processing Capacity | Customizable (e.g., 3-10 HP) | Scalable to meet production demands from small batches to large-scale ops. |

| Automation Level | Integrated sensors, PLC controls, and AI-driven quality checks | 20% faster than traditional models; minimizes labor costs. |

| Seed Removal Accuracy | Automatic separation with 99.9% efficiency | Eliminates manual sorting and reduces waste. |

| Multi-Fruit Compatibility | Optimized for mango, banana, pineapple, and papaya | Versatile for tropical fruit processing without equipment changes. |

Adjustable parameters include power output (to match energy requirements) and processing speed (to align with production targets). Custom sterilization protocols or packaging integration can be added for specialized needs.

With stainless steel construction, you can ensure hygienic processing in compliance with global food safety standards. With customizable power systems, you can scale operations to meet seasonal demand spikes.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Capacity | 300 kg/h (industry standard) | +20% (360 kg/h) | +50% (450 kg/h)* |

| Automation Level | Basic sensors & PLC | Smart controls (+40% efficiency) | AI integration (full autonomy) |

| Customization Options | Limited (power, speed) | Moderate (sterilization, packaging) | Full (material, output formats) |

Key Technical Breakthroughs:

Optimal Version Selection:

The Pro version’s 450 kg/h capacity (50% above industry benchmarks) enables round-the-clock production, while its AI integration optimizes energy use by 25%. Pair this with stainless steel durability, and you achieve a system that outperforms competitors in both speed and longevity.

Note: Comparative values assume industry-standard benchmarks of 300 kg/h and 70% automation efficiency.

⭐⭐⭐⭐⭐ Maria Gonzalez - Tropical Fruit Processing Facility

"We've been running the Pro Model since February 2025, and it has completely transformed our operation. The AI-driven quality control ensures every batch of mango puree meets export standards—no more inconsistencies. With a 450 kg/h capacity, we’re now processing double what we used to with half the labor. The 99.9% seed removal accuracy is no exaggeration; we’ve seen almost zero pulp waste. Stainless steel construction holds up perfectly in our humid environment, and daily cleaning takes less than 20 minutes thanks to the built-in rinse cycle."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Carter - Caribbean Tropical Farms

"As a small farm supplying local juice bars and farmers’ markets, the Base Model was the perfect entry point. Purchased in October 2024, we’ve been using it for six months and already recouped over 60% of the investment. It handles mangoes, pineapples, and even papayas with ease. I was skeptical about automation at this scale, but the touchscreen controls are intuitive—even my staff with no technical background picked it up in a day. The ability to customize processing speed has been crucial during off-season when volumes drop."Purchase Date: October 2024 | Usage Period: 6 months

⭐⭐⭐⭐☆ Sofia Ramirez - Island Fresh Juice Bar

"We upgraded to the Advanced Model in January 2025 to keep up with summer demand. It’s been solid—processing around 360 kg/h means we can prep all our tropical bases in just two morning hours. The modular packaging integration lets us fill jars and vacuum bags seamlessly, which is great for retail sales. Only reason I’m not giving five stars is that the initial setup required a technician visit (not included), but once running, it’s been flawless. Sterilization cycles run automatically, which gives us peace of mind for food safety audits."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Ahmed Ndiaye - West African Agro-Processing Hub

"We process mangoes for European and Middle Eastern markets, so compliance is non-negotiable. This machine is FDA and EU certified, and the sealed stainless steel system prevents any contamination—critical for passing inspections. Since deploying the Pro Model in March 2025, we’ve reduced labor costs by 60%, thanks to full automation. We also customized the packaging line for 1L and 3L export-grade aseptic bags, and the supplier delivered precise integration without delays. After five months of continuous use, not a single mechanical fault."Purchase Date: March 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Elena Petrova - Southeast Asia Food Co-op

"Our co-op processes banana, pineapple, and mango seasonally, so we needed something versatile. The multi-fruit compatibility of this line is its biggest strength. Switching between fruits takes under 15 minutes—no hardware changes, just a quick calibration on the touchscreen. We bought the Advanced Model in August 2024 and have been using it for eight months now. The custom sterilization protocols we added have helped us meet regional export requirements, and the stainless steel body hasn’t shown a single sign of corrosion despite high humidity."Purchase Date: August 2024 | Usage Period: 8 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Linda Foster - Agricultural Engineering Consultant

"Having evaluated over 30 fruit processing systems in the past decade, I can confidently say this mango processing line sets a new benchmark. The combination of stainless steel hygiene, AI integration, and modular scalability makes it ideal for both emerging and established tropical fruit producers. The Pro Model’s energy optimization and 99.9% seed separation efficiency are unmatched in the current market."

Rajiv Mehta - Global Food Safety & Sustainability Specialist

"This equipment aligns with ISO 22000 and FDA standards, making it one of the few truly compliant solutions for exporters. Its eco-friendly design, including energy-efficient motors and recyclable material use, supports ESG goals. For small and mid-sized processors aiming for global market access, this is the most future-proof investment available today."

Posted: 2 days ago

"Processing 450 kg/h with full automation has allowed us to fulfill contracts we previously had to decline. The AI monitoring alerts us to any deviations in viscosity—critical for maintaining consistency. Extremely satisfied with after-sales support too."

Posted: 1 week ago

"We replaced two older plastic-based machines with one Pro Model. It paid for itself in six months. The stainless steel build is indestructible, and the customization for barrel filling saved us thousands in third-party packaging."

Posted: 3 weeks ago

"Machine performs excellently. Only feedback: the touchscreen interface lacks Vietnamese language options, which slows down training for new operators. Otherwise, durability and automation are top-tier."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.