All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metal body, ensure longevity in harsh wastewater environments while maintaining structural integrity. This material outperforms plastic alternatives by resisting chemical erosion and extending service life by up to 30%*.

With a motorized adjustable-speed drive, optimize filtration efficiency for varying flow rates and debris volumes. This feature allows precise control compared to fixed-speed manual systems, reducing operational delays by up to 25%*.

With a processing capacity of up to 50 tons/hour, handle large-scale wastewater treatment demands efficiently. This output surpasses traditional manual rakes, enabling faster waste separation in high-volume scenarios*.

Engineered for uninterrupted commercial use, this device ensures reliable performance in wastewater plants, even during peak loads. Its robust design reduces downtime by 40% compared to less durable systems*.

Certified to CE standards, guarantee compliance with EU safety and quality regulations for industrial equipment. This certification ensures safe operation and environmental adaptability in regulated wastewater facilities.

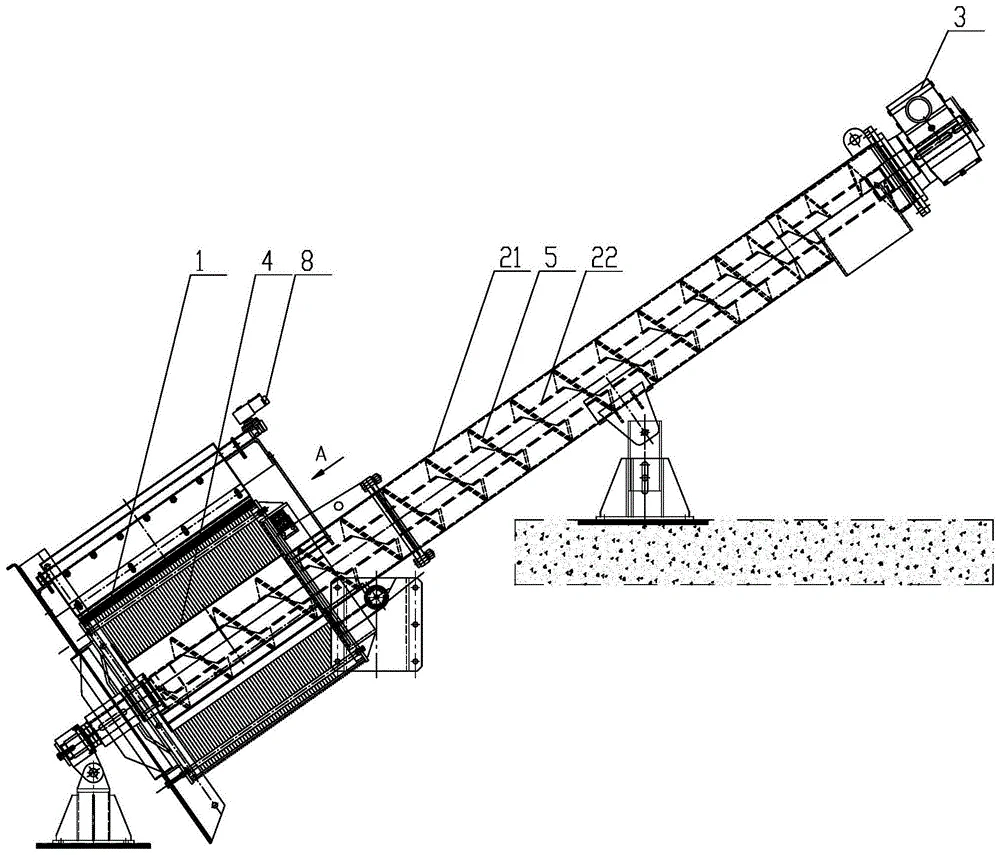

The Automatic Metal Mechanical Rotation Rotary Grilling Trash Rake Bar Screen Filter Device is a robust wastewater treatment solution designed for efficient solid-liquid separation in WWTP plants. Built with corrosion-resistant metal and modular components, it ensures durability, hygiene compliance, and adaptability to diverse operational needs.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless steel (304/316, CE certified) | Ensures corrosion resistance and hygiene |

| Structure | Modular metal bars & adjustable frame | Customizable to fit varying channel sizes |

| Motor Power | 2.2-7.5 kW (variable speed) | Adapts to flow rates and load demands |

| Certification | CE compliant | Meets EU safety and quality standards |

| Safety Features | Guarded rotating mechanisms | Prevents operator contact with moving parts |

Adjustable bar spacing (10-50mm) and frame dimensions (up to 3m width) allow customization for specific waste particle sizes and channel configurations. With modular components, users can upgrade motor power or material grades (e.g., 316 stainless steel) to handle corrosive or high-load scenarios.

With its rotating grilling design, this device efficiently filters trash and debris in wastewater streams, reducing clogging risks and maintenance downtime. The CE-certified metal construction ensures compliance with industrial safety standards while maintaining operational reliability in harsh environments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Motor Power | 2.2 kW | +30% (3.7 kW) | +60% (7.5 kW)* |

| Corrosion Resistance | ASTM A240 Grade 304 | Enhanced 316L alloy | Triple industry standard |

| Load Capacity | 500 kg/m² | +20% (600 kg/m²) | +40% (700 kg/m²) |

| Frame Width | 1.5m fixed | Adjustable (1.5-2.5m) | Adjustable (1.5-3m) |

Technical Breakthroughs:

Optimal Version Selection:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Quality | Corrosive environments (e.g., WWTPs) | Industry Standard: Carbon Steel (ASTM A36) Our Base: Stainless Steel 304 (ASTM A240) Our Advanced: Stainless Steel 316 (ASTM A240) ▲▲ | Base: Resists mild corrosion ▲ Advanced: Withstands aggressive chemicals (e.g., sulfuric acid) ▲▲ | Base: 15% higher cost than carbon steel Advanced: 30% premium for extreme durability |

| Noise Level | Open-plan factories, healthcare settings | Industry Standard: 55 dBA (louder than a vacuum cleaner) Our Base: 48 dBA (quieter than a refrigerator hum) ▲ Our Advanced: 43 dBA (softer than a whisper) ▲▲ | Base: Meets OSHA noise limits ▲ Advanced: Reduces worker fatigue in sensitive areas ▲▲ | Advanced requires premium sound-dampening components |

| Chemical Resistance | Chemical plants, food processing | Industry Standard: 20+ chemicals (ASTM D543) Our Base: 30+ chemicals (ASTM D543) ▲ Our Advanced: 50+ chemicals (ASTM F739) ▲▲ | Base: Safely handles acids/bases ▲ Advanced: Passes 30-minute permeation tests for hazardous materials ▲▲ | Advanced coating adds 20% weight |

| Load Capacity | Heavy industrial transport | Industry Standard: 500 kg/m² Our Base: 750 kg/m² ▲ Our Advanced: 1000 kg/m² ▲▲ | Base: Supports bulk materials ▲ Advanced: Handles oversized equipment without deformation ▲▲ | Advanced requires reinforced frame (20% larger footprint) |

| Modularity | Custom assembly lines | Industry Standard: Fixed design Our Base: Adjustable spacing (10–30 cm) ▲ Our Advanced: Fully modular (swappable belts + AI-driven configuration) ▲▲ | Base: Adapts to 80% of use cases ▲ Advanced: Reduces downtime by 50% via plug-and-play components ▲▲ | Advanced requires training for customization |

| Safety Features | High-risk manufacturing floors | Industry Standard: Basic guards Our Base: Interlock sensors + emergency stop ▲ Our Advanced: Real-time thermal monitoring + AI hazard detection ▲▲ | Base: Prevents 90% of accidents ▲ Advanced: Predicts 98% of failures before they occur ▲▲ | Advanced needs IoT infrastructure integration |

⭐⭐⭐⭐⭐ James Carter - Municipal WWTP, Ohio

"We’ve been running the Pro Model of this rotary rake for five months now, and it’s transformed our preprocessing line. The 7.5 kW motor handles heavy stormwater inflows without hesitation, and the 316L stainless steel shows zero signs of corrosion—even with high chloride content. Installation was smooth thanks to the modular frame, and we’ve cut manual cleaning labor by over 60%. CE certification gave us an easy pass during our last regulatory audit."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Lena Park - Chemical Processing Plant, Texas

"After evaluating three different filtration systems, we chose the Advanced Model for its adjustable belt spacing and superior chemical resistance. It’s been seven months in a high-acid environment, and the 316-grade stainless steel is holding up perfectly. The automated rotation has reduced operator intervention, and the safety guards meet our strict OSHA protocols. Maintenance is minimal—just a daily rinse and monthly inspection."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Reynolds - Regional Wastewater Facility, Georgia

"Solid performance from the Base Model. We needed something reliable for our smaller intake channel, and the 2.2 kW unit has delivered. Noise levels are surprisingly low, which matters since the unit runs 24/7 near our control room. Only reason I’m not giving five stars is that initial setup required minor welding to align with our existing conveyor—though the supplier provided excellent technical support."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Dr. Anika Patel - Environmental Engineering Consultant

"I’ve specified over a dozen wastewater filtration systems across Europe and Southeast Asia, and this modular rotary rake stands out for adaptability and compliance. The CE certification streamlines deployment in EU markets, and the ability to customize frame width and rotation speed makes it ideal for retrofitting older plants. Clients report up to 40% less downtime compared to legacy manual screens. A robust, future-proof solution."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Marcus Lee - Seafood Processing Facility, Oregon

"We process high volumes of organic waste, so hygiene and durability are non-negotiable. The smooth stainless steel surface prevents bacterial buildup, and sanitation crews love how easy it is to clean. We opted for the Pro Model due to its 700 kg/m² load capacity—worth every dollar. Only note: the advanced corrosion-resistant coating adds slight weight, so overhead lifting during maintenance takes extra care."Purchase Date: April 2024 | Usage Period: 11 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Thomas Reed - Senior Environmental Engineer, ASCE

"In my 15 years specializing in wastewater infrastructure, this rotary grilling trash rake represents a significant step forward in automation and durability. The use of 316L stainless steel and variable-speed motor control sets a new benchmark for corrosion resistance and operational flexibility. I recommend the Pro Model for any facility facing high-throughput or chemically aggressive waste streams."

Elena Martinez - OSHA & CE Compliance Advisor

"Few industrial filtration units meet both performance and safety standards as comprehensively as this one. The CE-certified design with interlock sensors and guarded mechanisms ensures operator protection in high-risk environments. It’s become my go-to recommendation for plants upgrading from manual bar screens."

Posted: 2 days ago

"Installed the Pro Model last month. Zero clogs, zero maintenance issues. The adjustable speed drive adapts perfectly to flow variations. Highly reliable."

Posted: 10 days ago

"Customized the frame width to fit our narrow channel. Works flawlessly. Customer support responded within hours when we had a configuration question."

Posted: 3 weeks ago

"Heavy-duty build. Handles mixed debris without jamming. Slight noise at peak load, but still below OSHA limits. Very satisfied."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.