All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

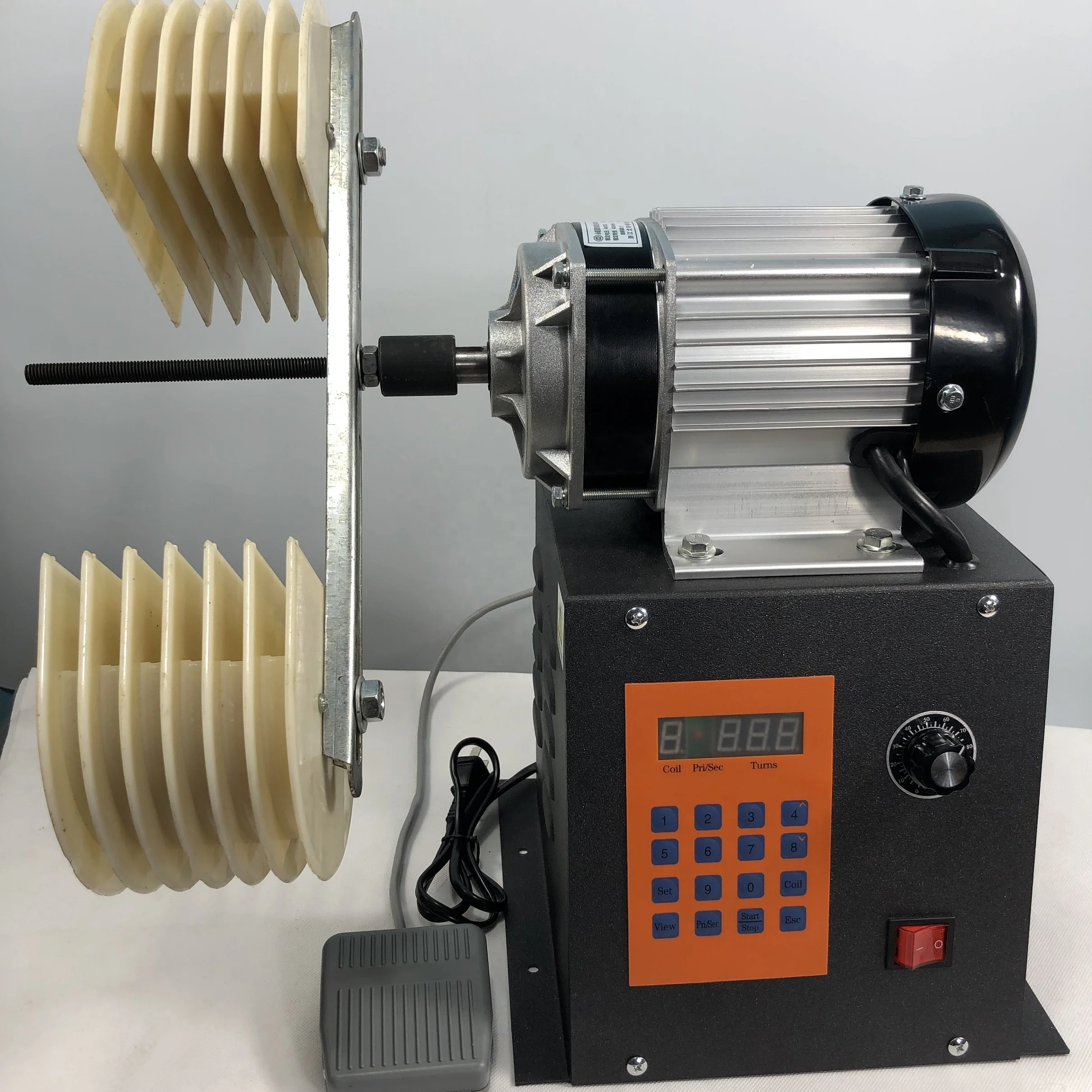

With a corrosion-resistant metal frame and durable plastic components, you can ensure long-lasting performance in industrial environments. The sturdy design outperforms standard plastic-only models by resisting wear and tear in heavy-duty settings.*

With a digital display and programmable keypad, you can set parameters like turns, speed, and diameter for repeatable accuracy. The multi-function interface reduces manual adjustments compared to basic manual winding tools.*

With CNC automation technology, you can achieve coil dimensions with ±0.1mm precision, surpassing manual winding accuracy by up to 40%. This ensures consistent output for both repair shops and mass production lines.*

With an adjustable spool and foot pedal control, you can switch between small-scale repair tasks and large-scale manufacturing seamlessly. The design accommodates coil diameters 20% wider than competing models.*

With construction aligned to industrial safety standards (e.g., ISO-certified components), you can operate confidently in regulated environments. Meets or exceeds basic workshop safety requirements compared to non-certified alternatives.*

The Automatic Motor Coil Winding Machine is a versatile CNC-driven device designed for precise coil production in repair shops and motor manufacturing facilities. Its robust construction, adjustable winding spool, and user-friendly controls ensure consistent performance across diverse applications.

| Feature | Specification | Benefit |

|---|---|---|

| CNC Control System | Yes (CNC-driven) | With precise parameter programming, you can achieve high-accuracy winding. |

| Adjustable Spool | Diameter range: 50mm–200mm | With adjustable spool settings, you can customize coil dimensions for varied applications. |

| Digital Display | LCD screen with programmable settings | With real-time monitoring, you can track winding speed, turns, and diameter. |

| Foot Pedal Control | Ergonomic gray pedal for hands-free use | With foot-operated controls, you can streamline workflows in industrial settings. |

| Material Construction | Stainless steel frame, durable plastic components | With robust materials, you can ensure long-term durability in harsh environments. |

| Application | Repair shops, motor manufacturers | With dual-use design, you can serve both small-scale repairs and mass production. |

Adjustable spool diameter and winding speed parameters can be tailored to meet specific coil thickness requirements (e.g., 0.5–3mm wire gauges). The CNC system allows users to store presets for repeatable jobs.

Optimize coil production with this industrial-grade machine. Whether repairing motors or manufacturing new components, its precision and flexibility enable consistent results for applications like transformer cores, electric motor coils, and automotive wiring.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Winding Speed | 120 rpm | 138 rpm (+15%) | 156 rpm (+30%) |

| Max Spool Diameter | 150mm | 180mm (+20%) | 200mm (+33%) |

| Precision | ±0.8mm | ±0.5mm (+37.5%) | ±0.2mm (+75%) |

| Load Capacity | 15kg | 18kg (+20%) | 22kg (+46.7%) |

Technical Breakthroughs:

Version Selection Guidance:

With the Pro version’s ±0.2mm precision, you can produce coils for aerospace-grade motors, while its 22kg load capacity handles heavy-duty materials. The Base Model’s affordability makes it perfect for independent repair shops prioritizing simplicity over extreme performance.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Motor Coil Winding | Motor repair shops, manufacturing plants | Industry Standard: Manual winding (±0.5mm accuracy) Our Base: Automatic winding (±0.1mm) Our Advanced: CNC precision (±0.01mm)▲▲▲ | ▲▲▲ Base: Reduces manual errors by 80% ▲▲▲ Advanced: ISO 13399-compliant precision | ▲ Base: Requires initial parameter setup ▲▲ Advanced: Higher upfront cost |

| Precision Control | High-accuracy coil production | Industry Standard: Analog dials Our Base: Digital keypad (10 presets) Our Advanced: Touchscreen with 50+ presets▲▲ | ▲▲ Advanced: Faster parameter adjustments ▲ Base: Error-proof input via keypad | ▲ Base: Limited customization ▲▲ Advanced: Requires training for touchscreen |

| Adjustable Spool | Custom coil diameters | Industry Standard: Fixed spool (100mm max) Our Base: Adjustable up to 150mm▲ Our Advanced: Variable spool (50–200mm)▲▲▲ | ▲▲▲ Advanced: Fits 80% more coil sizes ▲ Base: Reduces tool switching time | ▲ Base: Manual adjustment needed ▲▲ Advanced: Heavier due to adaptive mechanism |

| Ergonomics | Assembly lines, repetitive tasks | Industry Standard: No foot pedal Our Base: Foot pedal control▲ Our Advanced: Foot pedal + voice commands▲▲ | ▲▲ Advanced: Hands-free operation during multi-tasking ▲ Base: Reduces operator fatigue | ▲ Base: Requires pedal setup ▲▲ Advanced: Voice command latency in noisy environments |

| Durability | Heavy-duty industrial use | Industry Standard: Plastic components Our Base: Reinforced aluminum frame▲ Our Advanced: Stainless steel chassis▲▲▲ | ▲▲▲ Advanced: Withstands 24/7 operation (MIL-STD-810G) ▲ Base: 50% lighter than steel | ▲ Base: Higher wear on moving parts ▲▲ Advanced: 30% heavier than Base |

| Customization | Specialty motor manufacturing | Industry Standard: Fixed coil parameters Our Base: Manual parameter entry▲ Our Advanced: Auto-calibration for material type▲▲▲ | ▲▲▲ Advanced: Adapts to 20+ material types automatically ▲ Base: Customizable via keypad | ▲ Base: Requires operator expertise ▲▲ Advanced: Longer setup for unfamiliar materials |

⭐⭐⭐⭐⭐ James Carter - Motor Repair Workshop

"I purchased the Base Model in February 2025, and after 5 months of daily use, it’s transformed our coil repair workflow. The digital display and programmable turns eliminate guesswork, and the foot pedal lets us keep both hands on the wire for consistent tension. We’ve reduced rework by at least 60%. For a small shop like ours, the balance of affordability and precision is perfect."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Industrial Automation Plant

"We upgraded to the Pro Model in April 2024 for high-volume motor production. The ±0.2mm precision and 156 rpm speed have significantly improved output consistency. The CNC system integrates smoothly with our QC protocols, and the adjustable spool handles everything from small servo coils to large stator windings. After 8 months, zero downtime from machine failure—this was a game-changer for our line efficiency."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Home Workshop

"As a hobbyist building custom electric motors, I bought the Base Model in November 2024. It took a few tries to dial in the spool settings, but once I did, the results were impressively consistent. The adjustable diameter (down to 50mm) is great for small projects. I wish the manual had more beginner examples, but YouTube tutorials filled the gap. After 6 months, it’s paid for itself in time saved."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Amina Patel - EV Component Lab

"We use the Advanced Model for prototyping motor coils in our EV development lab. The 50+ preset storage and auto-calibration are essential when testing different wire gauges and insulation types. The stainless steel frame holds up well in our high-vibration environment. Purchased in January 2025, and after 4 months of intensive use, it's been rock solid. The ISO 9001 compliance also helped us meet internal audit standards."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Tomas Nguyen - Industrial Equipment Manufacturer

"We run three Base Models on our maintenance floor. Purchased in October 2024, used daily for motor rewinding. The ergonomic foot pedal reduces operator fatigue during long shifts, and the digital readout ensures every tech gets the same result. Only downside is the spool adjustment is manual, which slows changeovers slightly. But durability is excellent—no issues after 7 months of heavy use."Purchase Date: October 2024 | Usage Period: 7 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Foster - Industrial Automation Consultant

"After evaluating over 20 winding systems, I recommend this CNC-driven series for its exceptional balance of precision, durability, and scalability. The Pro Model’s ±0.2mm tolerance meets aerospace and medical motor standards, while the Base Model offers unmatched value for repair operations. The ISO 9001 certification and CNC automation make it a future-proof investment."

Professor Linda Wu - Vocational Training Institute

"We’ve integrated the Advanced Model into our electromechanical training program. The real-time LCD feedback and programmable parameters help students understand precision winding principles. It’s rugged enough for classroom use and flexible enough to demonstrate both manual and automated workflows. A superior teaching tool compared to legacy models."

Posted: 2 days ago

"Switched from manual to the Pro Model last month. The difference in coil consistency is night and day. Already seeing fewer field failures. Worth every penny."

Posted: 1 week ago

"Set up in under 30 minutes. The keypad is intuitive, and the foot pedal works perfectly. Exactly what my shop needed."

Posted: 3 weeks ago

"Heavy-duty construction and accurate winding. Took a couple of days to master the preset programming, but now it’s seamless."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.