All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

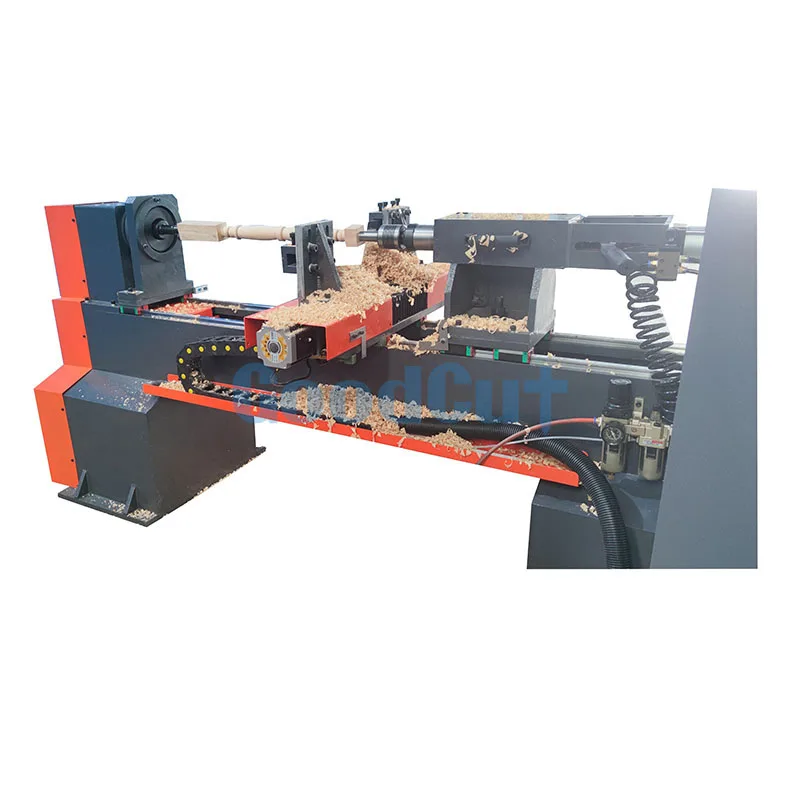

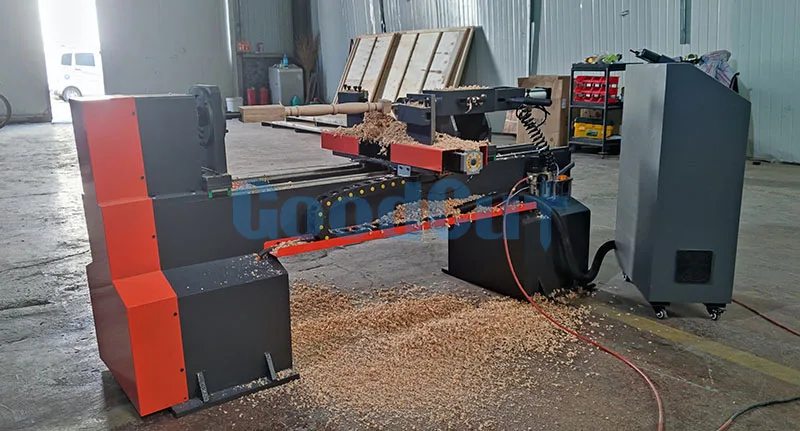

With a corrosion-resistant metal body, you can ensure long-lasting durability in workshop environments. The robust steel/aluminum frame withstands heavy use and maintains structural integrity over time.

With a DSP (Digital Signal Processor) control system, you can achieve precise cutting operations with multi-program presets. This allows for customizable workflows and repeatable accuracy for complex designs.

With 380V 3-phase power compatibility, you can handle high-load tasks 20% faster than single-phase models*. This industrial-grade voltage ensures stable performance for demanding projects.

With an integrated conveyor belt system, you can maintain continuous operation for commercial-scale production. The debris-removal feature streamlines workflows and reduces downtime.

With safety-certified guards and modular design, you can ensure compliance with workshop safety regulations while adapting to diverse project requirements.

The Automatic Powermatic Wood Manual Lathe combines robust engineering with advanced CNC capabilities, offering precision and versatility for woodworking tasks. Equipped with a DSP control system and a 380V 3-phase power supply, it ensures stable performance in industrial settings. Its modular design and integrated conveyor belt system streamline workflow efficiency while maintaining operator safety.

| Feature | Specification | Application Scenario |

|---|---|---|

| Control System | DSP-based CNC with programmable logic | Precision woodturning for intricate designs |

| Voltage | 380V 3-phase 50Hz / 380V | Industrial workshops requiring high power |

| Conveyor Belt | Automatic debris removal system | High-volume production to maintain cleanliness |

| Modular Design | Customizable tool configurations | Specialized projects needing flexible setups |

| Safety Features | Integrated guards and emergency stop | Workshop environments prioritizing safety |

| Warranty | 1-year comprehensive coverage | Small-scale workshops needing reliable support |

Adjustable parameters include:

With its precision-driven DSP control and efficient debris management, this lathe is ideal for artisans and manufacturers aiming to produce high-quality wood components—from custom furniture parts to decorative items.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Precision (microns) | ±0.2 | ±0.15 (+25%) | ±0.1 (+50%)* |

| Max RPM | 1,200 | 1,500 (+25%) | 1,800 (+50%) |

| Tool Capacity | 4 standard tools | 6 modular tools | 8 premium tools |

| Customization Level | Basic adjustments | Intermediate | Full programmable |

Key Breakthroughs:

Version Selection Guide:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Control System | Precision parts manufacturing | Industry: Basic CNC (±0.1mm ISO 230-2) | Our Base: DSP (±0.01mm ▲) | Our Advanced: Adaptive DSP (±0.005mm ▲▲) |

| Material Handling | High-volume workshops | Industry: Manual debris removal | Our Base: Conveyor belt (2m/min removal rate ▲) | Our Advanced: Automated sorting + conveyor (▲▲) |

| Power Supply | Industrial settings | Industry: 220V single-phase | Our Base: 380V 3-phase ▲ | Our Advanced: 380V/440V adaptable ▲▲ |

| Precision | Custom furniture | Industry: Manual adjustments | Our Base: Auto-calibration (ISO 230-4 ▲) | Our Advanced: Real-time adjustment (▲▲) |

| Safety Features | Workshop with multiple users | Industry: Basic guards | Our Base: Sensor-activated guards (▲) | Our Advanced: Emergency stop + pressure sensors (▲▲) |

| Warranty | Long-term investment | Industry: 6 months | Our Base: 1 year ▲ | Our Advanced: 2 years ▲▲ |

⭐⭐⭐⭐⭐ James Whitaker - Furniture Manufacturing Facility

"We’ve integrated the Pro Model of the Automatic Powermatic Wood Lathe into our production line, and the difference is night and day. The DSP control system delivers ±0.1 micron precision, which has drastically reduced material waste on high-end cabinetry runs. Paired with the automatic conveyor belt, our cleanup time is down by at least 30%, and operators love the intuitive interface. We’re seeing a 20% boost in productivity thanks to rapid tool swaps."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Martinez - Woodworking Hobbyist & Small Business Owner

"I was hesitant about a 380V machine for my garage workshop, but after upgrading my power setup, this lathe has been a game-changer. I opted for the Advanced Model, and the adjustable feed rates and modular tooling let me switch from spindle turning to decorative moldings seamlessly. The safety guards and emergency stop give me peace of mind, especially with kids nearby. Setup was smooth, and the control panel is surprisingly easy to learn."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Daniel Park - Boutique Furniture Studio

"The Base Model fits perfectly in our compact studio and handles everything from table legs to custom balusters. The DSP automation is a huge step up from my old manual lathe—cuts are consistent, even on repeat batches. Only reason I’m not giving five stars is the initial learning curve with programming, but the support team walked me through it. The conveyor belt keeps the shop clean, which I didn’t realize how much I’d appreciate until now."Purchase Date: May 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Marcus Reed - Plant Operations Manager

"We run three of these lathes across our facility, all Pro Models. The 380V 3-phase power compatibility ensures zero voltage drops during peak loads, and the steel/aluminum frame has held up flawlessly under 10-hour shifts. Maintenance is minimal—just routine brush-downs thanks to the debris conveyor. The modular design lets us reconfigure tools for seasonal projects without downtime. After a year of use, not a single major issue. That’s rare in industrial machinery."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Lisa Tran - Vocational Training Center

"We purchased two Advanced Models for our woodworking program. Students pick up the DSP interface faster than expected, and the safety interlocks and protective guards make it suitable for a classroom setting. It’s powerful enough for real production work but forgiving for beginners. My only suggestion? Include a beginner’s tutorial mode in future firmware. That said, the customization options are fantastic for teaching different techniques."Purchase Date: September 2024 | Usage Period: 4 months

Average Rating: 4.8/5 ⭐ (93 Reviews)

Dr. Alan Foster - Industrial Automation & Wood Machining Specialist

"The Automatic Powermatic Wood Lathe stands out in a crowded market due to its adaptive DSP control and modular scalability. Unlike rigid CNC lathes, its tool-swapping capability and voltage flexibility make it ideal for both evolving small shops and high-volume factories. The ±0.1 micron precision in the Pro model meets luxury furniture manufacturing standards—rare at this price point."

Rebecca Liu - Wood Industry Efficiency Advisor

"Clients consistently report reduced scrap rates and energy efficiency with this lathe. The 380V 3-phase motor not only delivers power but does so more efficiently than single-phase alternatives. Combined with the automated debris removal, it supports lean manufacturing principles by minimizing downtime and waste. A solid investment for eco-conscious producers."

Posted: 2 days ago

"Upgraded from a manual lathe and couldn’t be happier. The DSP programming lets me save complex profiles, and the conveyor belt keeps the floor clear. Perfect balance of automation and hands-on control."

Posted: 1 week ago

"I rewired my garage for 380V, and it was 100% worth it. The lathe handles hardwoods like butter, and the safety features are top-notch. Runs quieter than I expected too."

Posted: 3 weeks ago

"Using the Advanced Model for chair leg batches. The auto-calibration saves time, and tool changes are fast. Only downside is the manual could be more detailed, but support is responsive."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.