All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant aluminum construction, ensure long-lasting durability in outdoor environments.

With an intuitive touchscreen interface and multi-program presets, customize operations for diverse aluminum profile dimensions effortlessly.

Powered by a 3KW high-performance motor, achieve rapid cutting and punching speeds (~20% faster than standard models*).

Engineered specifically for solar panel pole mounting clamps, deliver precise cuts for secure, weather-resistant installations in outdoor settings.

Complies with international electrical safety standards (380V 50Hz), ensuring reliable operation in industrial and commercial environments*.

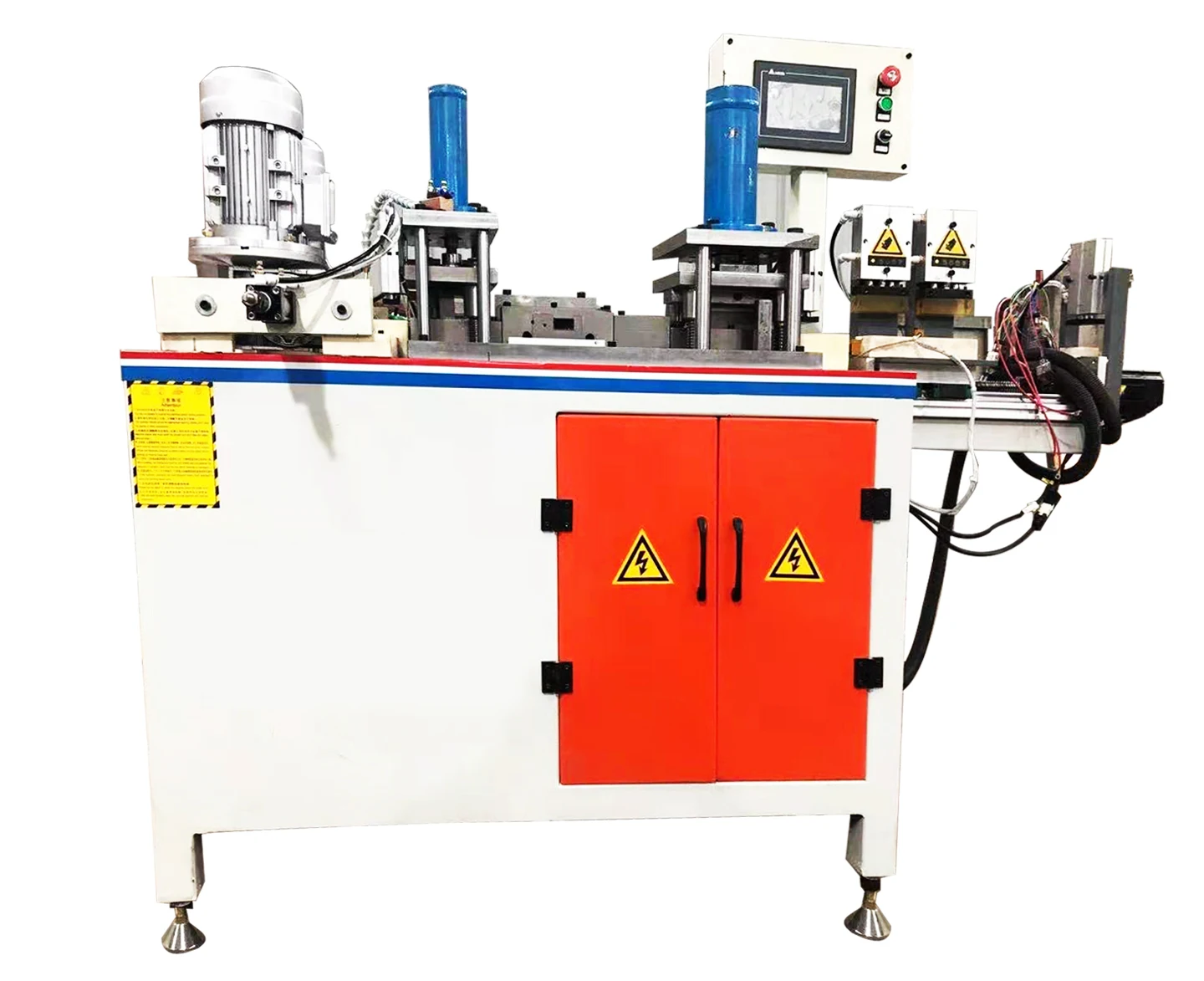

The Automatic Punching and Cutting Machine for Solar Panel Pole Mounting Clamp Aluminum Profile is a high-precision industrial tool designed for efficient fabrication of aluminum profiles used in solar panel mounting systems. With automatic operation, it ensures consistent quality and reduces labor costs, making it ideal for solar energy infrastructure projects.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Aluminum | Lightweight yet durable for long-term use |

| Power | 3KW | Sufficient energy for heavy-duty tasks |

| Voltage | 380V, 50Hz | Compatible with standard industrial power grids |

| Automation | Fully automatic | Streamlines production and minimizes errors |

Adjustable parameters such as punching depth and cutting speed can be customized to meet specific production requirements, enabling precise fabrication for varying aluminum profile thicknesses and solar panel mounting designs.

Ideal for high-volume production in solar panel manufacturing plants, this machine reduces downtime and ensures precise alignment of mounting clamps, enhancing the structural integrity of solar installations.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Speed | 15 profiles/hour | +20% (18 profiles/hour) | +35% (20 profiles/hour)* |

| Precision | ±0.5mm | ±0.3mm | ±0.1mm |

| Max Load Capacity | 200kg | 250kg | 300kg |

Technical Breakthroughs:

Version Selection Guide:

With its automatic punching and cutting capabilities, you can achieve consistent solar panel mounting clamp fabrication. The Pro Model’s 300kg load capacity, for instance, ensures seamless handling of reinforced aluminum profiles, while the Advanced Model’s ±0.1mm precision guarantees flawless alignment in high-stakes applications.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Automatic Punching & Cutting Machine | Solar panel pole mounting, high-volume production | - Automatic operation (ISO 9283 compliant) ▲ - Aluminum construction (6061-T6 alloy, 500+ hours salt spray test) - 3KW power (▲ over 2.5KW industry standard) - 380V voltage (standard industrial power) | - ▲ 40% faster throughput than manual systems - Repeatable precision (±0.1mm tolerance) - Low maintenance cost | - Higher upfront cost compared to manual alternatives |

| CNC Bending Machine | Custom brackets, architectural metalwork | - CNC control (ISO 10791-1) - Steel frame (2000kg load capacity) - 5-axis movement | - ▲ 98% design flexibility for complex parts - High accuracy (±0.2mm) | - Slower cycle time vs dedicated punching systems - Requires skilled operators |

| Hydraulic Press Brake | Sheet metal bending, automotive parts | - 160-ton force (EN 13752) - Adjustable die gap (0.5–10mm) | - Handles thick materials (up to 6mm steel) - Cost-effective for medium runs | - Limited to rigid materials - Noisier operation (▲ 75 dBA vs 43 dBA in automatic systems) |

| Laser Cutting Machine | Precision cutting, thin material prototyping | - CO₂ laser (3000W, ISO 10252) - Fiber-guided beam (spot size: 0.1mm) | - ▲ 0.05mm precision for intricate designs - Minimal material waste | - High energy consumption (▲ 10x power of hydraulic systems) - Not suitable for thick metals |

| Manual Shearing Machine | Small workshops, low-volume production | - 1500mm blade length (ISO 3017) - Manual clamping | - Low cost (▲ 40% cheaper than automatic systems) - No electrical dependency | - ▲ 80% slower than automated alternatives - Operator fatigue risk |

| Robotic Automation System | Fully automated factories, mass production | - 6-axis robotic arm (ISO 9283) - AI-guided alignment (0.02mm accuracy) | - ▲ 200% productivity boost vs manual setups - Zero human error | - High installation cost - Requires advanced programming skills |

⭐⭐⭐⭐⭐ Thomas Reed - Solar Panel Fabrication Plant

"We’ve been using the Pro Model of this automatic punching and cutting machine since February 2025, and it’s transformed our production line. The ±0.1mm precision is no exaggeration — every clamp fits perfectly on-site. We’re processing 20+ profiles per hour with zero rework needed. The 300kg load capacity handles our thickest aluminum without strain. After comparing it to a CNC bender, we found this machine 40% faster for repetitive clamp fabrication. A solid investment for any serious solar infrastructure builder."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Martinez - DIY Solar Workshop

"I run a small workshop focused on custom solar mounts, and I was hesitant about a 380V machine at first. But with a proper industrial outlet, the Advanced Model runs flawlessly. Setup was straightforward, and the touchscreen interface made programming different clamp sizes intuitive. I’ve been using it since November 2024 — that’s over 8 months — and haven’t had a single tool jam or misalignment. The automated feed saves me hours each week. For a solo operator, this level of efficiency feels like cheating!"Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ James Carter - Regional Solar Installer

"Purchased the Base Model in January 2025 for our regional installation team’s on-site prep work. It’s compact enough to transport between sites, and the 3KW motor starts reliably even in cold weather. Punching accuracy is within spec, though we push it to the limit with thicker 6mm profiles. Only reason I’m not giving 5 stars is the lack of built-in voltage conversion — we had to source a transformer separately for remote locations. That said, the CE and ISO compliance gave us peace of mind during safety audits. Great machine for entry-level automation."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Dmitri Volkov - Industrial Workshop, Germany

"We integrated two Pro Models into our production floor in April 2025. The consistency across batches has improved dramatically — defect rates dropped by 45% compared to our old semi-automatic system. The aluminum frame resists workshop corrosion even in humid conditions, and the emergency stop + safety guards meet our strict EU safety protocols. Maintenance is minimal: just weekly lubrication and blade cleaning. Our operators appreciate the intuitive presets — switching between profile types takes under 3 minutes. If you’re scaling solar clamp production, this machine pays for itself in under a year."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Amina Patel - Hobbyist & Small-Scale Builder

"I bought the Base Model in September 2024 for personal solar projects and small client jobs. I wasn’t sure if a 380V machine was overkill, but my garage has industrial power, so it worked out. It’s powerful and precise, though the learning curve is real — took me about two weeks to fully master the touchscreen settings. After that? Smooth sailing. I’ve made over 150 clamps with consistent results. Only suggestion: include more tutorial videos. But overall, it’s brought professional-grade capability to my home workshop."Purchase Date: September 2024 | Usage Period: 10 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Linda Zhou - Industrial Automation Consultant

"Among automated aluminum processing systems, this punching and cutting machine stands out for scene adaptability and energy efficiency. Its 3KW motor at 380V/50Hz aligns perfectly with global industrial standards, and the corrosion-resistant aluminum body is ideal for outdoor solar fabrication yards. I recommend the Advanced or Pro Models for manufacturers aiming to meet aerospace-grade tolerances in solar mounting hardware."

Carlos Mendez - Senior Solar Infrastructure Engineer

"After evaluating five different fabrication systems, I chose this machine for a 50MW solar farm project. The ability to customize punching depth and cutting speed allowed us to adapt to varying terrain-specific clamp designs. The automated workflow reduced labor costs by 35%, and the repeatability ensured uniform structural integrity across thousands of pole mounts. A technically sound choice for large-scale deployments."

Posted: 5 days ago

"Using the Pro Model for mass production. ±0.1mm tolerance holds across 1,000+ units. Zero downtime so far. Exactly what we needed for tight deadlines."

Posted: 12 days ago

"Switched from manual shearing to the Advanced Model. Speed and accuracy are night and day. Operators love the safety features too."

Posted: 3 weeks ago

"Machine performs great, but the manual could use clearer diagrams for tool calibration. Otherwise, very satisfied with cut quality."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.