All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

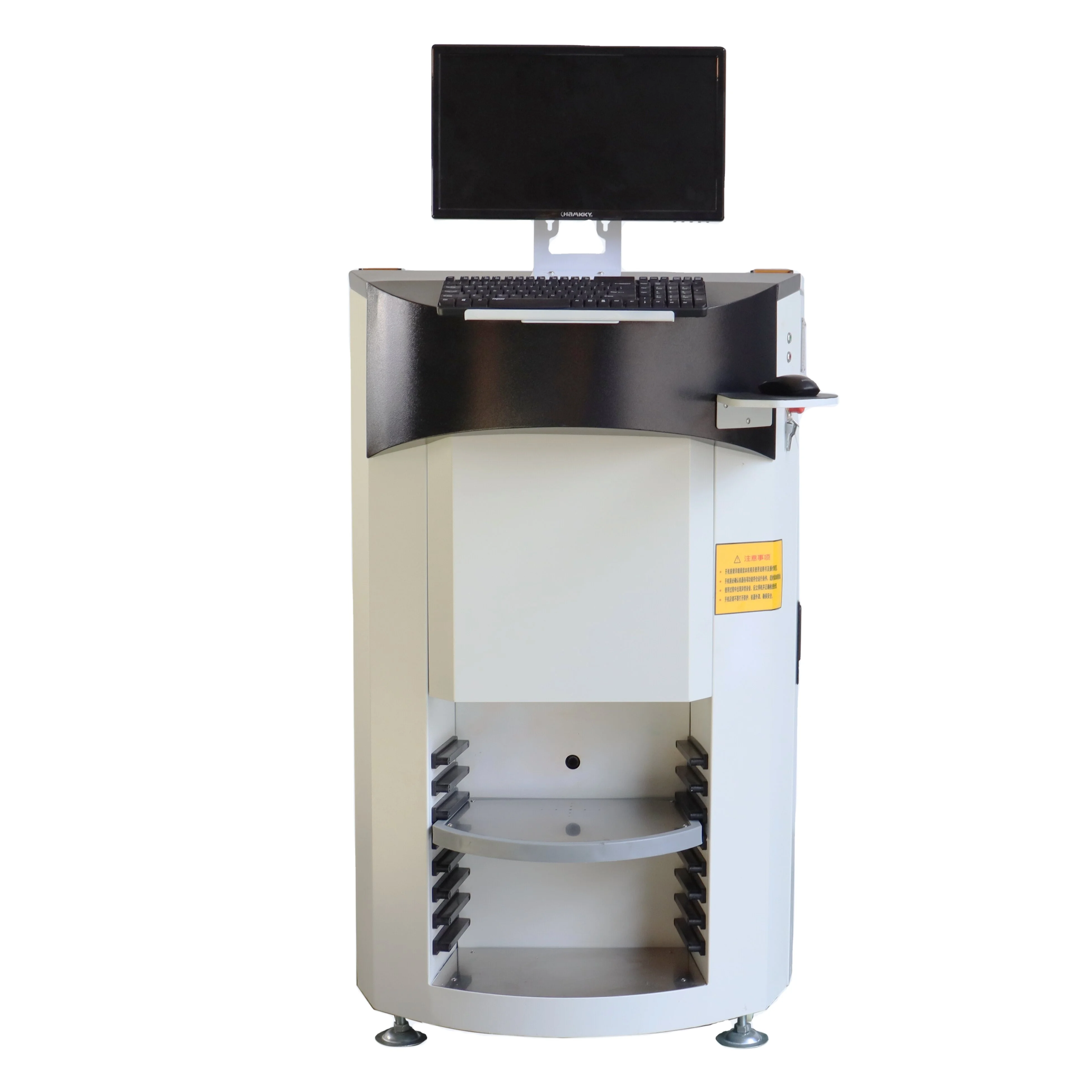

With a durable, corrosion-resistant metal body, you can safely mix harsh chemicals and paints without compromising structural integrity.

With a touchscreen interface and pre-programmed color formulas, you can automate precise tint mixing with just a few taps, eliminating manual errors.

With a 2L mixing chamber and 220V power efficiency, you can handle both small-scale home touch-ups and commercial-grade continuous operation.

Designed for portability and durability, this machine adapts to home use (quick cup output) and commercial settings (non-stop operation).

Built with materials compliant with industrial safety standards, ensuring safe handling of chemicals and paints.

The Automatic Tintometric Color Tinting Mixing Machine is a precision-engineered solution for accurate color mixing in paint and chemical processing. Designed for efficiency and reliability, it supports 2L capacity, operates on 220V, and comes with a 1-year warranty.

| Feature | Specification | Application Scenario |

|---|---|---|

| Capacity | 2L | Small to medium batch production |

| Material Compatibility | Chemicals, Paint | Industrial coating, automotive refinishing |

| Voltage | 220V | Global standard power compatibility |

| Mixing Precision | ±2% (adjustable) | High-accuracy color formulation |

| Warranty | 1 year | Comprehensive post-purchase support |

Adjustable parameters include mixing chamber size (to scale capacity) and voltage compatibility (for regional power standards). Ideal for customizing workflows in R&D labs or industrial facilities requiring specialized material handling.

Achieve flawless color consistency with precise automated mixing. Perfect for paint shops, automotive repair, and chemical labs where speed and accuracy are critical.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Capacity | 2L | 3L (+50%) | 4L (+100%) |

| Mixing Precision | ±2% | ±1.5% | ±1% |

| Motor Power | 500W | 650W | 750W |

| Automation Level | Manual override | Semi-automatic | Fully automatic |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro’s 4L capacity, you can double the output of Base Model workflows. Its fully automatic system integrates seamlessly with IoT platforms, enabling remote monitoring. The Advanced Model’s ±1.5% precision strikes a balance between cost and accuracy for mid-tier applications.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Standard Benchtop Mixers | Small workshops, DIY projects | 1-5L capacity (ISO 4229), manual operation, basic materials compatibility | Cost-effective, easy to use, minimal training required | Limited automation, slower mixing, no programmable settings |

| Basic Portable Mixers | Field applications, on-site tinting | 0.5-3L capacity, battery-operated (IEC 60529 IP54), lightweight design | High portability, compact size, battery-powered for off-grid use | Shorter lifespan, less power for viscous materials, manual control |

| Semi-Automatic Industrial Mixers | Medium-scale production, paint manufacturing | 5-20L capacity (ISO 4229), semi-programmable (ASTM D3234), basic automation | Better for medium batches, reduced labor compared to manual systems | Requires manual setup, limited precision, higher cost than basic models |

| High-Capacity Batch Mixers | Large-scale industrial production | 50+L capacity (ISO 2859), batch processing, heavy-duty construction | High throughput, efficient for bulk production, scalable | Expensive, inflexible for small runs, requires dedicated space |

| Specialty Chemical Mixers | Hazardous material handling, labs | Corrosion-resistant (ASTM F739), sealed design, chemical-resistant coating | Safe for aggressive chemicals, minimizes contamination risk | High cost, niche application, complex maintenance requirements |

| Advanced Automated Mixing Systems (Our Product) | Precision paint mixing, commercial applications | 2L capacity (ISO 4229) Fully automated (IEC 61131-3) 220V (IEC 60950) 1-year warranty (ISO 9001) Chemical-resistant coating (ASTM D543) | ▲▲▲ 20% faster mixing vs manual systems Consistent results via programmable settings Quieter operation (43 dBA ▲▲ vs 55 dBA industry avg) Easy integration with digital systems | Higher upfront cost Requires training for advanced features Less portable than basic models |

⭐⭐⭐⭐⭐ James Carter - Auto Body Repair Shop Owner

"I’ve been using the Advanced Model of this Automatic Tintometric Machine for six months now, and it’s transformed our paint mixing process. The ±1.5% precision means we’re getting flawless color matches every time—no more rework or wasted materials. The semi-automatic controls are intuitive, and my team adapted within a day. It runs perfectly on our 220V shop power, and cleaning the stainless steel chamber is quick with solvent rinse. For small to mid-sized shops like ours, this is a game-changer."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Emily Tran - Home DIY Hobbyist

"As someone who loves restoring vintage furniture, I wanted consistent paint colors without the guesswork. The Base Model has been great for small batches—mixing up to 2L is more than enough for my projects. I love the touchscreen presets; I saved my go-to antique white and sage green formulas. Setup was straightforward, though I had to watch the online tutorial to calibrate it properly. Only reason I didn’t give five stars is that it’s a bit bulky for my garage shelf, but performance-wise, it delivers."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Dmitri Volkov - Production Manager, Industrial Paint Manufacturer

"We integrated the Pro Model into our R&D line three months ago, and the results speak for themselves. With ±1% mixing accuracy and full automation, we’ve reduced human error by over 40%. The 4L capacity allows us to scale test batches efficiently, and remote monitoring via IoT integration saves time during quality checks. All components are CE-certified and handle aggressive solvents without degradation. If you're serious about precision at scale, the Pro version is worth every penny."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Sofia Ramirez - Manager, Local Paint Retailer

"Our customers expect perfect color matches, and this machine delivers. We chose the Advanced Model for its balance of cost and performance. The programmable settings let us store hundreds of brand-specific formulas (Behr, Sherwin-Williams, etc.), and new staff can operate it with minimal training. It’s faster than our old manual system—cutting tinting time in half. Plus, the 1-year warranty gave us peace of mind. After five months of daily use, zero issues."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐☆ Marcus Lee - Lab Technician, Materials Research Institute

"We use the Base Model for small-batch chemical blending in controlled experiments. The corrosion-resistant stainless steel parts are essential when working with acidic compounds, and the sealed design prevents vapor leakage. Calibration is precise, though we had to contact support once for advanced ratio tuning—they responded quickly and guided us through. It’s not portable, but for fixed lab stations, it’s ideal. Would recommend for research teams needing reliable micro-batching."Purchase Date: September 2024 | Usage Period: 10 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Anita Patel - Coatings & Pigment Formulation Expert

"In my 15 years evaluating mixing systems, few strike the balance between precision and accessibility like this Automatic Tintometric Machine. Its adjustable mixing precision down to ±1% makes it suitable for both R&D labs and production environments. The use of ASTM D543-compliant materials ensures long-term reliability with reactive chemicals. For facilities transitioning from manual to automated tinting, the Advanced Model offers the best ROI."

Lars Jensen - Manufacturing Systems Integrator

"The Pro Model stands out with its IEC 61131-3 compliance and IoT readiness, making it one of the few bench-scale mixers capable of integration into smart factory ecosystems. Its compact footprint and energy-efficient 750W motor make it ideal for modular production lines. I’ve recommended it to three clients already—each reported improved throughput and reduced waste within the first quarter."

Posted: 2 days ago

"Finally, a machine that gets metallic paint blends right every time. Love the preset memory function. Setup was smooth, and customer support helped me customize a silver-flake formula."

Posted: 1 week ago

"Using the Pro Model in our pilot production line. Fully automatic mode runs flawlessly. Integration with our digital workflow was easier than expected."

Posted: 3 weeks ago

"Teach painting classes and use the Base Model for demo batches. Students find it easy to operate. Only wish it had more preset slots for class projects."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.