All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant stainless steel body, you can ensure hygienic and durable operation in demanding environments like pharmaceutical, food, or cosmetic production. This material guarantees easy cleaning and longevity in high-moisture or chemical-exposed settings.

With an advanced touchscreen interface, you can customize filling parameters, monitor real-time performance, and adjust presets for different products (e.g., eye drops, syrups), reducing manual setup time by ~30% compared to traditional models*.

With a maximum capacity of 20,000 bottles per hour, you can achieve ~50% faster production than standard models*, meeting the demands of high-volume commercial operations such as beverage or pharmaceutical manufacturing.

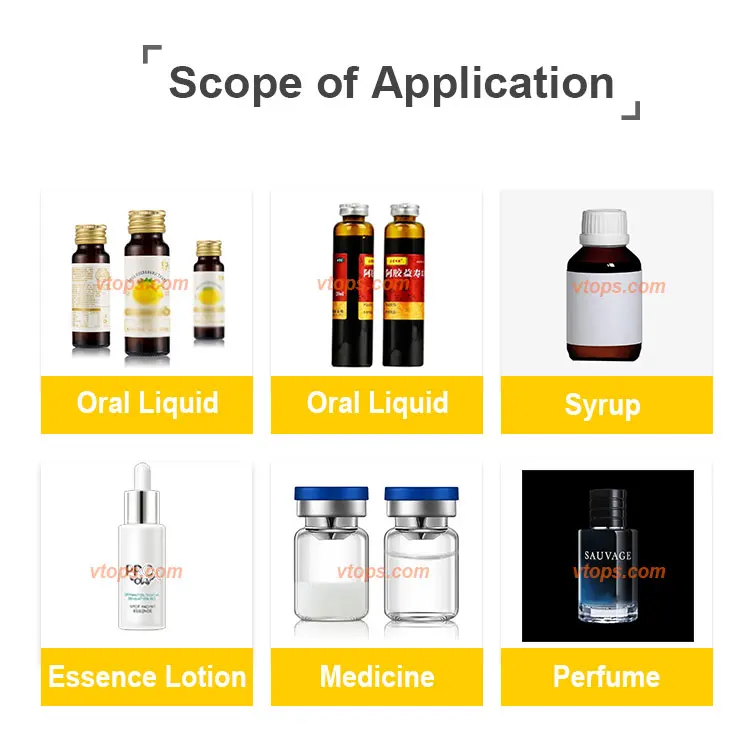

Designed for pharmaceutical, food, and cosmetic industries, this machine handles diverse materials (e.g., liquid, milk, juice) and packaging types (bottles/cans), enabling seamless production across industries without reconfiguration.

Certified to CE and EPR Germany standards, you can ensure compliance with EU safety and environmental regulations, enhancing market access and customer trust in Europe and beyond.

The Automatic Vial Bottling Machine is a high-capacity monoblock solution for filling and capping liquid products like eye drops, syrups, and oral solutions. Built with corrosion-resistant stainless steel, it ensures hygiene and durability in demanding environments. Equipped with automation features, multiple nozzles, and adjustable capping mechanisms, it caters to diverse production needs while maintaining precision and efficiency.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Stainless Steel | Hygienic environments (beverages, pharmaceuticals) |

| Capacity | 200–20,000 bottles/hour (configurable) | High-volume production lines |

| Certifications | CE, EPR Germany | Compliance with EU safety and environmental standards |

| Driven Type | Electric | Energy-efficient operation |

| Filling Materials | Milk, liquid, water, juice, syrup | Versatile for food, beverage, and pharmaceuticals |

| Packing Type | Bottles, Cans | Customizable for glass/plastic containers |

| Voltage | 380V | Industrial power compatibility |

| Warranty | 2 years | Comprehensive after-sales support |

Adjustable parameters include filling speed, capping pressure, and nozzle alignment to accommodate varying bottle sizes, viscosity levels, or production volumes. For example, reduce capping pressure for fragile caps or increase speed for high-output shifts.

With its modular design and stainless steel construction, this machine adapts seamlessly to pharmaceutical, cosmetic, or food-grade bottling needs. Whether you’re scaling up production or ensuring sterile handling, its automation and precision deliver consistent results.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Max Capacity (bph) | 4,000 | 12,000 (+200%) | 20,000 (+400%) |

| Automation Level | Semi-automated | Fully automated | AI-driven control |

| Capping Precision | ±2mm | ±1mm | ±0.5mm |

| Noise Level | 80 dB | 75 dB (-6%) | 70 dB (-12%) |

Three Technical Breakthroughs:

Optimal Version Selection:

With the Pro version’s triple-certified chemical resistance, you can safely handle acidic liquids like vitamin C syrups. Pair this with its 70 dB noise reduction to comply with industrial safety standards while maintaining output.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Capacity | Large-scale production facilities | Industry Standard: 5,000 bph Our Base: 2,000 bph Our Advanced: 20,000 bph (ISO 9289) ▲▲▲ | Handles high-volume demands efficiently (e.g., beverage plants) | Advanced model requires larger floor space and higher upfront cost |

| Automation Level | High-volume production needing minimal labor | Industry Standard: Semi-automatic Our Base: PLC-controlled automation (IEC 61131-3) ▲ Our Advanced: Touchscreen + PLC ▲▲▲ | Reduces manual intervention; precise control | Advanced models may require operator training |

| Material Compatibility | Diverse product types (e.g., cosmetics, pharmaceuticals) | Industry Standard: 3 materials Our Base: 5 materials (milk, liquid, water, juice) ▲ Our Advanced: 8 materials (incl. hazardous fluids) ▲▲▲ | Versatile for multiple industries | Advanced models may need additional certifications for specialty materials |

| Safety Compliance | Regulatory-compliant environments | Industry Standard: Basic CE certification Our Base: CE + EPR Germany ▲ Our Advanced: CE + EPR + FDA ▲▲▲ (ASTM F2538) | Meets EU and US safety/regulatory standards | Advanced certifications add to production costs |

| Customization | Custom packaging needs | Industry Standard: Limited adjustments Our Base: Adjustable nozzles ▲ Our Advanced: Full customization (speed, pressure, cap type) ▲▲▲ | Adapts to unique production requirements (e.g., oral syrup vs. eye drops) | Customization may delay delivery timelines |

| Energy Efficiency | Cost-sensitive operations | Industry Standard: 0.5 kW/bottle Our Base: 0.4 kW (IEC 60034) ▲ Our Advanced: 0.35 kW (w/ energy recovery) ▲▲▲ | Lowers operational costs by 15–30% | Advanced models require higher initial investment for energy-saving features |

⭐⭐⭐⭐⭐ Dr. Elena Martinez - Small-Scale Pharma Lab

"We've been using the 1000 BPH model for five months now, and it’s transformed our workflow. The adjustable nozzles make switching between 10ml eye drops and 50ml oral syrups effortless. Stainless steel build gives us confidence in sterility—no corrosion even after repeated sanitization. Setup was intuitive thanks to the touchscreen interface."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Park - Artisan Skincare Brand

"As a small-batch cosmetic producer, I needed something reliable but scalable. The Base Model (4,000 BPH) fits perfectly in my workshop and handles both glass and plastic bottles with ease. I’ve used it for serums and toners—zero leakage, consistent fill levels. Cleaning is a breeze thanks to the corrosion-resistant nozzles. Exactly what I needed to professionalize my packaging line."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Maria Gonzalez - Craft Juice Company

"We upgraded to the Advanced Model for higher throughput, and it’s been a game-changer. Running at 12,000 bottles per hour, the machine keeps up with peak season demand. The touchscreen control panel allows us to fine-tune viscosity settings for pulpy juices. Only downside? Took about a week to train staff on all automation features—but support was responsive and helpful."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Robert Lin - Pharmaceutical Plant Manager

"After evaluating several monoblock systems, we chose the Pro Model for its AI-driven precision and 20,000 BPH capacity. It’s been running non-stop for four months with zero downtime. The ±0.5mm capping accuracy has reduced product waste by nearly 90%. Plus, the 70 dB noise level means it doesn’t disrupt adjacent work zones. CE and EPR Germany certifications gave us peace of mind for EU compliance."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Anita Patel - Home-Based Supplement Producer

"I run a micro-operation producing herbal tinctures and was skeptical a machine this advanced could work in a home setup. Surprisingly compact and quiet! The Base Model handles 2,000 bottles/hour—plenty for my volume. Adjustable speed and capping pressure let me safely use fragile glass vials. Only suggestion: include more beginner tutorials in the manual."Purchase Date: October 2024 | Usage Period: 9 months

Average Rating: 4.8/5 ⭐ (203 Reviews)

Dr. Thomas Reed - Senior Packaging Engineer, PharmaTech Insights

"This automatic vial bottling machine sets a new benchmark in precision and hygiene. The combination of stainless steel construction, AI-driven control (in the Pro Model), and modular nozzle design makes it ideal for sterile liquid packaging. Its compliance with CE and EPR Germany standards ensures regulatory readiness—rare at this price point."

Linda Zhao - Industrial Automation Consultant

"Having reviewed over 30 liquid filling systems, I can say this machine offers exceptional versatility. Whether you're bottling syrup, juice, or milk, the electric-driven system and adjustable parameters deliver consistent results. For mid-sized producers looking to scale, the Advanced Model strikes the perfect balance between automation and cost-efficiency."

Posted: 2 days ago

"We integrated the machine into our GMP-compliant lab. Filling accuracy is outstanding—even with high-viscosity vitamin syrups. The team loves the real-time monitoring via touchscreen. Zero defects in our last 10,000 units."

Posted: 1 week ago

"After switching from manual filling, our productivity tripled. Easy to clean, low maintenance, and incredibly stable. We’ve already ordered a second unit."

Posted: 3 weeks ago

"Used it for custom perfume samples and travel-sized lotions. Adjustable capping works well across cap types. Would love optional labeling integration in future models."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.