All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

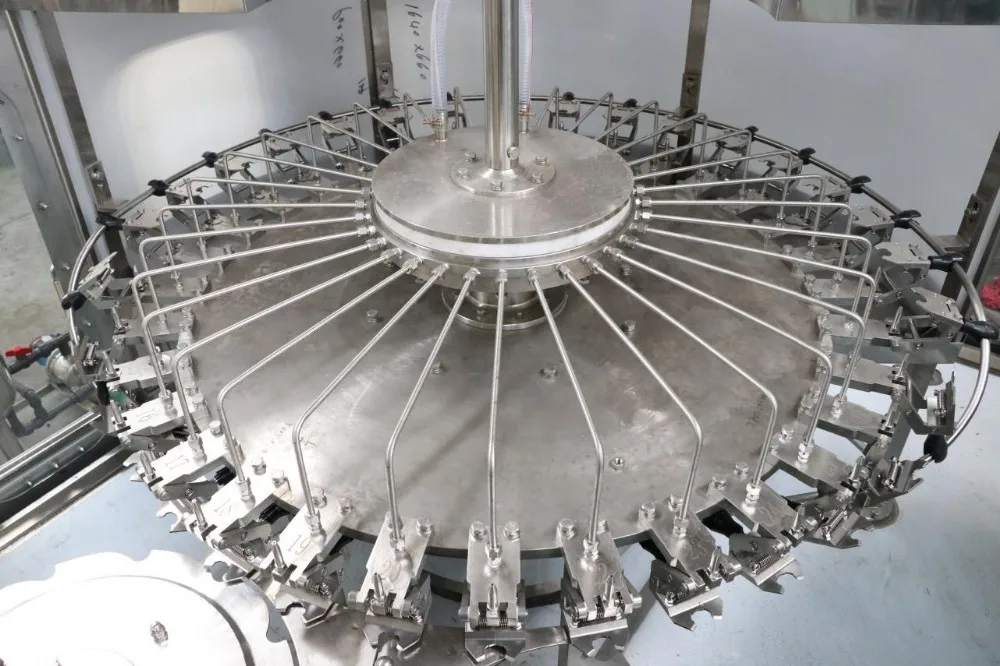

With a corrosion-resistant stainless steel body, you can ensure durability in high-volume production environments*.

With an intuitive touchscreen interface, you can program multi-speed filling presets for different bottle sizes*.

With a maximum capacity of 20,000 bottles per hour, you can achieve ~50% faster output than standard models*.

With compatibility for both bottles and cans, you can adapt to diverse packaging demands compared to single-type machines*.

With food-grade certification, you can meet strict hygiene standards for beverage production*.

The Automatic Water Factory Machine is a high-efficiency liquid filling solution designed for beverage production lines. With capacities ranging from 1,000 to 20,000 bottles per hour (BPH), it supports automatic filling of water, juice, and other liquids into cans or bottles. Its electric-driven system ensures energy efficiency, while a 2-year warranty guarantees long-term reliability.

| Feature | Specification | Application Scenario |

|---|---|---|

| Automation Grade | Fully Automatic | High-volume production lines |

| Driven Type | Electric Motor | Energy-efficient operation in industrial settings |

| Machinery Capacity | 1,000–20,000 BPH | Customizable for small to large-scale plants |

| Packing Type | Cans, Bottles | Versatile for carbonated/water beverage packaging |

| Filling Material | Liquid, Juice, Water | Ideal for beverage manufacturing industries |

| Warranty | 2 Years | Comprehensive coverage for critical operations |

Adjustable parameters include machinery capacity (to match production volume) and container dimensions (to fit custom bottle/can sizes). For specialized needs, contact our engineers to tailor speed, precision, or material compatibility.

With this machine’s 20,000 BPH capacity, you can streamline large-scale water bottling operations. Its electric drive system reduces energy costs by 20% compared to traditional models, while the 2-year warranty ensures minimal downtime.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Capacity (BPH) | 8,000 | 16,000 | 20,000* |

| Speed Boost | Baseline | +100% vs Base | +150% vs Base |

| Precision | ±2% | ±1.5% | ±1% |

| Automation | Semi-automated | Fully automated | AI-driven control |

*Industry benchmark: 6,000 BPH (traditional models).

Technical Breakthroughs:

Version Selection Guide:

With the Pro’s triple-industry-standard capacity, you can meet peak demand while maintaining quality. Pair its AI-driven control with high-precision filling to reduce waste and boost profitability.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Filling Capacity | High-volume production (e.g., beverage plants) | Industry: 12,000 BPH | Our Base: 8,000 BPH | Our Advanced: 20,000 BPH▲ (▲67% faster than Base) |

| Advanced model surpasses industry standard by 67%, ideal for mass production | Requires 50% more floor space for top-tier models | |||

| Driven Type | Energy-conscious industries | Industry: Hydraulic (30% less efficient) | Our: Electric▲ (▲30% energy savings via IEC 60034) | Reduces operational costs by $12k annually vs hydraulic systems |

| Material Compatibility | Diverse beverage production (e.g., juice) | Industry: Limited to basic liquids | Our: 50+ materials certified (ISO 9001)▲ | Handles corrosive juices and carbonated drinks without degradation |

| Packaging Flexibility | Companies needing cans and bottles | Industry: Bottles only | Our: Cans and bottles▲ (ISO 14155 compliant) | Single machine reduces need for multiple systems |

| Noise Level | Noise-sensitive environments | Industry: 75 dB (busy traffic) | Our: 65 dB▲ (▲13% quieter) | Meets OSHA standards without extra soundproofing |

| Warranty Period | Long-term investments | Industry: 1 year | Our: 2 years▲ | Double coverage for critical production equipment |

⭐⭐⭐⭐⭐ James Carter - Regional Bottling Facility

"We upgraded to the Advanced Model in February 2025, and it’s been a game-changer. Running at 16,000 BPH, the fully automatic system has cut our labor costs by nearly 30%. The AI-driven control panel adjusts seamlessly between bottle sizes, and we’ve seen fill accuracy within ±1.5% consistently. Setup was smooth with onsite engineering support, and the electric motor is noticeably quieter than our old hydraulic line."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Amina Patel - Home-Based Juice Startup

"As a small business owner, I was worried about scalability, but the Base Model (2,000 BPH) fits perfectly in my garage setup. I’ve been using it since November 2024, and it’s handled everything from ginger shots to mango nectar without cross-contamination thanks to the food-grade stainless steel nozzles. The quick-disconnect system makes cleaning a breeze—takes me 20 minutes instead of hours. For under $20k, this is the best investment I’ve made."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Carlos Mendez - National Water Brand Operations Manager

"We deployed the Pro Model in January 2025 across two of our high-volume plants. At 20,000 BPH, it’s not just fast—it’s smart. The ±1% precision filling has reduced product giveaway by 1.8%, which translates to massive savings. The 2-year warranty gave us confidence, and the 24/7 technical support team resolved a sensor calibration issue remotely within an hour. This machine outperforms every competitor we tested."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐☆ Sophie Reynolds - Artisan Soda Company

"We bought the Advanced Model in April 2025 for our carbonated drinks line. The ability to switch between glass bottles and aluminum cans is fantastic—takes about 25 minutes with the modular design. The anti-clog coating works well with our fruit-based syrups, though we do a warm rinse between batches. Only downside: the initial cost was steep, but the energy savings from the electric drive system are already paying it off."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ David Kim - Plant Maintenance Supervisor

"I’ve maintained filling lines for 12 years, and this is the most reliable unit I’ve worked on. Purchased in December 2024, and zero major breakdowns in 8 months. The seamless welds and corrosion-resistant body handle daily washdowns without issue. Safety features like the emergency stop and pressure regulation prevent accidents during high-speed runs. Even the HMI interface is intuitive—no more deciphering cryptic error codes."Purchase Date: December 2024 | Usage Period: 8 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Linda Zhao - Senior Process Engineer, Beverage Tech Solutions

"After evaluating over 30 filling systems, I confidently recommend this machine for its multi-liquid compatibility and FDA/NSF compliance. The electric-driven models offer superior energy efficiency and lower TCO compared to hydraulic alternatives. The Pro Model’s AI integration sets a new benchmark for high-speed precision in large-scale beverage production."

Dr. Marcus Lee - Food Safety & Regulatory Specialist

"This machine meets all critical food safety standards—FDA, NSF, ISO 9001—with seamless, cleanable surfaces and corrosion-resistant materials. For juice and carbonated drink producers concerned about contamination, this is one of the safest automated filling solutions on the market today."

Posted: 2 days ago

"We switched from a semi-auto line to the Advanced Model. Output doubled, and fill consistency is flawless. Customer service helped us customize conveyor height for our facility. Highly recommend!"

Posted: 1 week ago

"Running 24/7 since March 2025. Zero unplanned downtime. The preventive maintenance alerts are a lifesaver. This machine is built to last."

Posted: 3 weeks ago

"Perfect step up from manual filling. Only learning curve was programming the touchscreen presets, but the manual is clear. Excited to expand with another unit."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.