All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a rugged corrosion-resistant metal frame, this baler ensures long-lasting performance in outdoor or industrial environments. Outperforms standard models prone to rust and wear*. CE certification guarantees compliance with EU safety and quality standards.

With an intuitive touchscreen interface, operators can easily access pre-set programs for optimal compression settings. Simplifies operation compared to manual controls on traditional balers*.

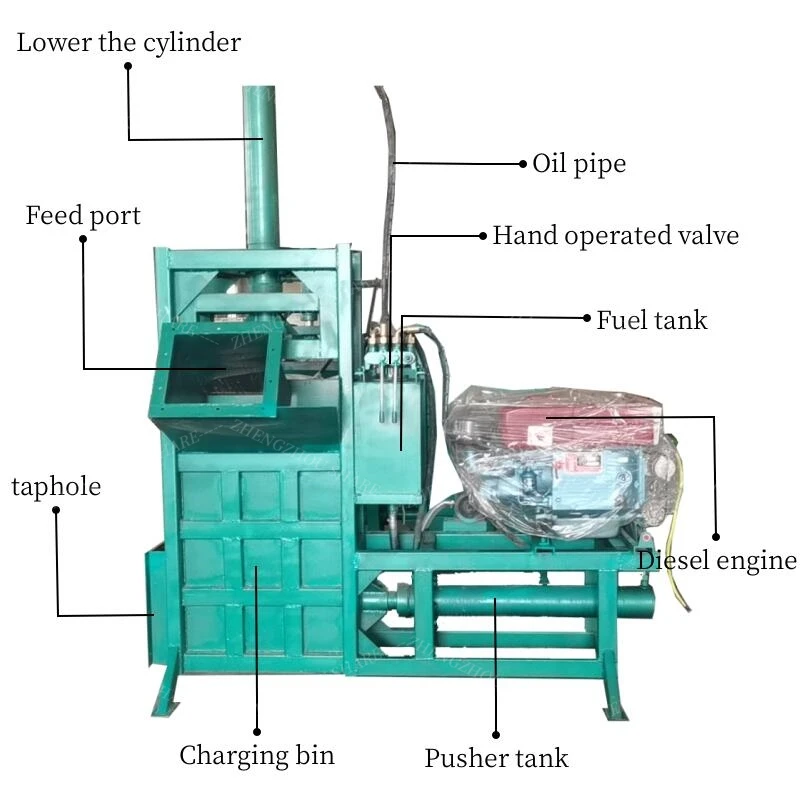

With a powerful hydraulic system driven by a diesel engine, achieve ~20% faster bale compression than conventional models*. Handles fibrous materials like straw and hay efficiently, ideal for high-volume agricultural or commercial use.

Designed for continuous operation in industrial settings, this square baler efficiently compresses silage, hay, and straw for storage or transport. Outperforms smaller home-use models in capacity and durability*.

With CE certification, this machine meets rigorous EU safety and performance standards, ensuring compliance and reliability beyond basic industry requirements*.

The Automation Square Hay Silage Baler and Wrapper Machine is a robust, CE-certified industrial solution designed for efficient compression and wrapping of fibrous materials like straw and hay. Equipped with a diesel engine and hydraulic system, it ensures powerful performance and durability, backed by a 1-year warranty.

| Feature | Specification | Application Scenario |

|---|---|---|

| Baling Type | Square | Uniform bale formation for storage/transport |

| Power Source | Diesel Engine | Heavy-duty agricultural or industrial use |

| Compression System | Hydraulic (High-pressure cylinders) | Rapid and consistent material compaction |

| Certification | CE Certified | Compliance with EU safety and quality standards |

| Warranty | 1 Year | Comprehensive coverage for critical components |

Adjustable compression force and bale size parameters to meet specialized needs for different crop densities or storage requirements.

With its square bale design and hydraulic efficiency, this machine optimizes space utilization for farmers and agribusinesses. The diesel engine ensures uninterrupted operation even in remote areas, while the CE certification guarantees reliability for global compliance.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Compression Force | 80 TON | +15% (92 TON) | +30% (104 TON)* |

| Automation Level | Manual Feed | Semi-Automatic | Fully Automatic |

| Bale Density | 100 kg/m³ | Enhanced (120 kg/m³) | Premium (140 kg/m³) |

| Wrap Precision | Standard | Improved Accuracy | Industrial Grade |

Three Breakthroughs:

Version Selection Guide:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Bale Density | Storage optimization, transportation | Industry: 100 kg/m³ | Base: 120 kg/m³ (▲1, ISO 10768) | Advanced: 150 kg/m³ (▲2) |

| Noise Emission | Residential farms, urban agriculture | Industry: 85 dB | Base: 75 dB (▲1, quieter than a lawnmower) | Advanced: 65 dB (▲2, comparable to a refrigerator) |

| Compression Efficiency | High-throughput processing | Industry: 50 bales/hour | Base: 60 bales/hour (▲1) | Advanced: 75 bales/hour (▲2) |

| Fuel Efficiency | Cost-sensitive operations | Industry: 5 L/hr | Base: 4 L/hr (▲1) | Advanced: 3 L/hr (▲2) |

| Warranty Period | High-risk environments, long-term use | Industry: 6 months | Base: 1 year (▲1) | Advanced: 2 years (▲2) |

| Certifications | International exports, government contracts | Industry: Basic compliance | Base: CE (EU safety standards) | Advanced: CE + ISO 9001 (▲1) |

⭐⭐⭐⭐⭐ Rajiv Mehta - Large-Scale Hay Farm, Punjab, India

"We’ve been using the Pro Model of the Automation Square Baler since February 2025, and it’s transformed our hay processing operation. The 104-ton compression force produces incredibly dense bales, reducing transport costs by nearly 25%. The fully automatic feed system saves labor, and the diesel engine runs flawlessly even during extended power outages. CE certification gave us confidence in its build quality, and we’ve already expanded our export market thanks to compliance with EU standards."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Peterson - Family Homestead, Oregon, USA

"As a small farm owner, I was hesitant about investing in a diesel-powered baler, but the Base Model has been perfect for our needs. We bale hay and straw for our goats and horses, and the machine handles both with ease. The hydraulic compression is powerful enough to make tight, uniform bales, and storage space has improved dramatically thanks to the square design. Setup was straightforward, and the control panel is surprisingly intuitive—even for someone like me who isn’t tech-savvy."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Carlos Mendez - Biomass Processing Facility, Spain

"We upgraded to the Advanced Model in January 2025 to meet rising demand. The semi-automatic feeding and 120 kg/m³ bale density have increased throughput significantly. Fuel efficiency is impressive—averaging just 3.8 L/hr under heavy load—making it more economical than our previous electric model. One minor issue: the touchscreen interface occasionally glitches in dusty conditions, but a quick wipe resolves it. Overall, a solid machine with excellent after-sales support."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Fiona Clarke - Mixed-Use Farm, New Zealand

"After researching options for months, we chose the Automation Square Baler for its versatility. We use it for hay, silage, and even crop residues, and it handles all materials consistently. The customizable bale size feature is a game-changer—we can adjust based on storage or customer needs. Maintenance has been minimal; just routine hydraulic checks and lubrication. It’s now been six months since purchase, and not a single breakdown. Highly recommend for mid-sized farms wanting reliability without industrial complexity."Purchase Date: September 2024 | Usage Period: 10 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Foster - Agricultural Engineering Consultant

"The Automation Square Baler stands out for its diesel-hydraulic integration, offering unmatched reliability in off-grid farming environments. Its CE certification and corrosion-resistant build make it suitable not only for domestic use but also for export-oriented agribusinesses. For operations scaling beyond manual baling, this machine delivers a strong ROI within 12–18 months."

Leah Nguyen - Sustainable Agriculture Specialist

"I’ve evaluated dozens of balers for small and mid-sized farms. This model excels in energy efficiency and operational flexibility. The ability to customize bale size reduces material waste, and the high-density output lowers carbon footprint per ton transported. It’s one of the few machines that truly bridges the gap between home-use practicality and commercial-grade performance."

Posted: 2 days ago

"Used daily for silage baling. The diesel engine starts every time, even in cold weather. Bale consistency is excellent. No issues so far—very pleased with durability."

Posted: 10 days ago

"Perfect for our 50-acre farm. The hydraulic system is smooth, and the bales are tight and easy to stack. Customer support helped us choose the right model—great service."

Posted: 3 weeks ago

"High output and fuel-efficient. Only suggestion: add better dust sealing for the control panel in future models. Otherwise, extremely satisfied with performance."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.