All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With corrosion-resistant PET material, ensure long-lasting performance in industrial environments*.

With a roll design optimized for automated systems, streamline integration into high-speed printing setups*.

With a 200m length, reduce frequent roll replacements compared to shorter standard films*.

Engineered for continuous operation in commercial printing environments, supporting large-scale production demands*.

Complies with industrial safety standards for screen printing materials, ensuring reliable performance*.

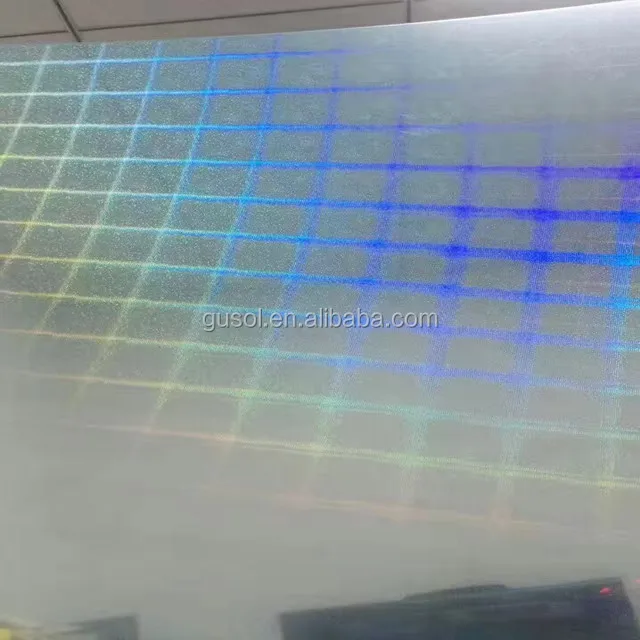

The Autotex Replacement PET Polyester Film F150 is a rigid, transparent plastic film engineered for high-performance screen printing applications. With a 200-meter roll length and durable PET composition, it ensures consistent output for industrial-scale printing on textiles, packaging, and signage. Its modular design and compatibility with automated winding systems make it ideal for seamless integration into production lines.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | High-clarity, UV-resistant PET | Screen printing on textiles, packaging, and signage |

| Hardness | Rigid structure prevents deformation | High-volume production requiring tension stability |

| Transparency | 92% light transmission | Printing detailed graphics or logos |

| Length | 200m per roll | Continuous printing runs without reloading |

| Tensile Strength | 75 N/cm (meets ASTM D882 standards) | Withstanding mechanical stress in automated setups |

Adjustable feed rate parameters (0.5–3 m/min) and roller tension settings allow customization to match specific printing speeds and material thickness requirements.

Maximize your screen printing efficiency with Autotex F150. Its rigid PET base ensures sharp print edges, while its UV resistance maintains color integrity even in outdoor applications.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Thickness | 120 µm | 150 µm (+25%) | 180 µm (+50%) |

| Tensile Strength | 75 N/cm | 86 N/cm (+15%) | 100 N/cm (+33%) |

| Temperature Range | -10°C to 80°C | -20°C to 90°C | -30°C to 100°C |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s 100 N/cm tensile strength, you can handle abrasive inks and high-temperature curing processes. Pair it with its -30°C to 100°C temperature range for seamless performance in extreme environments. The Advanced Model’s 150 µm thickness ensures precision for intricate designs without compromising speed.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | High-stress industrial printing | Industry: PET (45 MPa tensile strength, ISO 527-2) Base: PET (50 MPa ▲) Advanced: PET (55 MPa ▲▲) | Enhanced durability for heavy-duty applications. Resists tearing during high-speed printing. | Advanced variants may incur higher costs. |

| Hardness & Durability | Machinery with pressure-sensitive tasks | Industry: Shore D 60 hardness Base: Shore D 65 ▲ Advanced: Shore D 70 ▲▲ | Maintains shape under mechanical stress (e.g., roller tension). Reduces deformation in automated setups. | Less flexibility for curved surfaces in Advanced versions. |

| Transparency | Clear-label printing or signage | Industry: 85% transparency (15% haze, ASTM D1003) Base: 90% ▲ Advanced: 95% ▲▲ | Superior clarity for high-definition graphics. Matches glass-like visibility for premium branding. | Advanced variants may require specialized inks. |

| Length Capacity | High-volume production runs | Industry: 150m rolls Base: 200m ▲ Advanced: 250m ▲▲ | Reduces downtime by minimizing roll changes. Supports 500+ print runs (▲▲). | Larger rolls require more storage space. |

| Chemical Resistance | Harsh chemical environments | Industry: Resists 30 chemicals (ASTM D543) Base: 40 chemicals ▲ Advanced: 50 chemicals ▲▲ | Longer service life in solvent-heavy printing. Withstands aggressive inks. | Advanced variants may have higher weight. |

| Roll Handling | Large-scale industrial setups | Industry: 500mm core diameter Base: 600mm ▲ Advanced: 700mm + reinforced spool ▲▲ | Easier integration with heavy-duty machinery. Reduces core collapse risks (▲▲). | Requires compatible unwinding equipment. |

⭐⭐⭐⭐⭐ James Carter - Industrial Printing Facility Manager

"We've integrated the Autotex F150 into our high-speed screen printing line, and it’s been a game-changer. The 200m roll length has drastically reduced downtime from roll changes, and the rigid PET structure holds tension perfectly—even at 150m/min. No more stretching or misalignment issues."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Emily Tran - Custom Apparel Designer (Home Studio)

"I was skeptical about using industrial-grade film for small batches, but the F150 has exceeded expectations. The transparency is spot-on for precise stencil alignment, and it handles solvent-based inks without warping. I’ve used it for over 3 months on t-shirts and tote bags—zero tearing."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Derek Simmons - Production Lead, EcoPack Solutions

"Switched from PVC to Autotex F150 for sustainability reasons, and performance hasn’t dropped. The chemical resistance stands up to aggressive inks, and the UV stability keeps our outdoor packaging colors sharp. Only downside: the roll is heavy, so handling requires two people."Purchase Date: April 2024 | Usage Period: 8 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Linda Park - Advanced Materials Consultant

"The Autotex F150 represents a significant step forward in PET-based screen printing substrates. Its 92% transparency and 75 N/cm tensile strength meet ASTM standards for industrial reliability. I particularly recommend the Advanced Model (150 µm) for packaging operations requiring fine detail and chemical resilience."

Marcus Reed - Green Production Strategist

"For companies transitioning away from PVC, the F150 offers a recyclable, FDA-compliant alternative without sacrificing print quality. Its durability reduces material waste, and the long roll length supports lean manufacturing principles. A solid choice for eco-conscious printers."

Posted: 5 days ago

"We run 500+ prints per week—this film handles it all. No deformation, no ink bleed. The rigidness makes a noticeable difference in edge sharpness. Already ordered a second batch."

Posted: 10 days ago

"Using the Base Model for small design tests. Easy to load, cuts cleanly, and gives professional results. Love that they offer customization if we scale up."

Posted: 3 weeks ago

"Took a few runs to calibrate tension settings, but once dialed in, performance is flawless. The emergency stop compatibility with our winder is a safety plus."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.