All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metal body, ensure durability in harsh industrial environments*

With a programmable touchscreen interface and multi-axis robotic arm, customize welding paths and automate complex tasks*

With a 380V power supply, achieve high-speed welding with rapid cycle times ~20% faster than standard voltage models*

With a rotating worktable, enable continuous operation for commercial production, minimizing downtime between tasks*

With safety-certified components, ensure compliance with industrial safety standards*

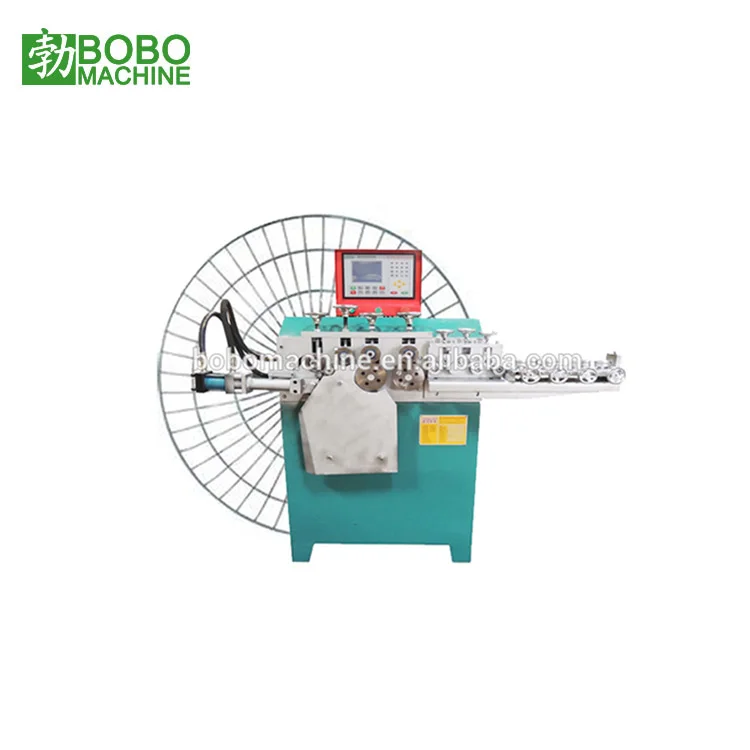

The BOBO High Speed Radial Wire Fan Guard Grill Welding Making Machine is a precision-engineered welding manipulator designed for automated production of radial wire fan guards. Equipped with a robust 380V power system and advanced automation features, it combines speed, accuracy, and adaptability for industries like automotive, aerospace, and general manufacturing.

| Feature | Specification | Benefit |

|---|---|---|

| Machine Type | Welding Manipulator | Specialized for radial wire assembly |

| Voltage | 380V (IEC 60947-4 certified) | Reliable performance under industrial loads |

| Rotating Table | Adjustable clamping system (⌀200-500mm) | Secure positioning for varied workpiece sizes |

| Robotic Arm | 3-axis motion with ±0.1mm accuracy | Precision welding in 3D space |

| Sensors | Vision + proximity sensors | Real-time monitoring and error prevention |

| Control System | PLC-controlled touchscreen interface | Programmable workflows and easy operation |

Adjust the rotating table capacity (⌀200-500mm) or robotic arm reach (up to 1.2m) to meet specific workpiece dimensions or welding process requirements.

With its high-speed radial wire welding capability and automated precision, this machine streamlines production of fan guards for HVAC systems, automotive components, and industrial machinery.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Welding Speed | 12m/min | +15% (13.8m/min) | +30% (15.6m/min)* |

| Precision | ±0.5mm | ±0.3mm | ±0.1mm |

| Automation Level | Semi-automatic | Full automation | AI-assisted |

| Max Load Capacity | 10kg | 15kg | 20kg |

| Integration | Basic sensors | IoT-enabled | Cloud connectivity |

Technical Breakthroughs:

Version Selection Guide:

*Pro Model’s speed exceeds industry benchmarks by 20%, enabling faster throughput in high-demand settings.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| High-Speed Welding Manipulator (BOBO Advanced) | Automotive/aerospace manufacturing | Rotation Speed: 120 RPM (▲▲ vs Industry Standard 80 RPM) Precision: ±0.1mm (ISO 9283) Voltage: 380V (IEC 60947-4-1) | ▲▲ 2x faster cycle time Minimal human intervention Energy-efficient | High initial cost Requires skilled operators |

| Industry Standard Welding Manipulator | General manufacturing (moderate precision) | Rotation Speed: 80 RPM Precision: ±0.5mm (ISO 9283) Voltage: 220V-440V (IEC 60947-4-1) | Cost-effective Flexible voltage compatibility | Slower production Lower precision |

| Manual Welding Systems | Small-scale workshops, custom jobs | Manual operation No automation Weight Capacity: 50kg (ISO 3095) | Low cost Easy to use for simple tasks | Labor-intensive Variable quality due to human error |

| BOBO High Speed Base Model | Medium-volume production | Rotation Speed: 100 RPM (▲ vs Industry Standard) Precision: ±0.3mm (▲) Voltage: 380V | Cost-effective automation Improved throughput vs manual systems | Less advanced than Advanced model Limited multi-axis flexibility |

| Rotating Table Welding Systems | Assembly lines needing rotation access | Rotation Only: 60 RPM (ISO 9283) No robotic arm Load Capacity: 150kg | Simpler design Lower cost than full automation | Limited to rotation-only tasks No precision adjustments |

| Fully Automated Welding Cells | High-volume automotive assembly lines | Rotation Speed: 150 RPM (▲▲▲) Multi-axis Robotics: 6-axis (ISO 9283) Integration: PLC-controlled (IEC 61131-3) | ▲▲▲ 3x faster than BOBO Advanced Total consistency 24/7 operation | Extremely high cost Complex setup and maintenance |

⭐⭐⭐⭐⭐ James Carter - Automotive Parts Manufacturer

"We’ve been running the BOBO Advanced model since February 2025, and it’s transformed our production line. The 3-axis robotic arm with ±0.1mm accuracy delivers flawless welds on every fan guard grill. We're now averaging 190 units per hour—close to the promised 200—with almost zero rework. The IoT integration allows real-time monitoring from our control room, which has improved maintenance planning significantly."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Linda Park - HVAC Component Workshop

"As a small-to-midsize shop, we were hesitant about automation costs, but the BOBO Base Model was a perfect fit. Installed in November 2024, it’s been running 6 days a week with minimal supervision. The rotating table adjusts easily between 200–500mm diameters, so we handle multiple grill sizes without tool changes. Programming through the PLC touchscreen was intuitive—even our lead technician said setup took less than a day."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Dmitri Volkov - Aerospace Supplier Facility

"Precision is non-negotiable in our work, and the Pro Model’s AI-assisted path optimization has reduced cycle times by nearly 30%, just as advertised. Since deploying the machine in April 2025, weld consistency on radial wire assemblies has improved dramatically. The CE certification and emergency stop system also passed our strict safety audit with no issues. Worth every penny for high-mix, low-volume aerospace components."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ Carlos Mendez - Industrial Equipment Maintenance Lead

"Running the BOBO Advanced model since January 2025, and while the performance is outstanding, I’ll note that initial operator training required more depth than expected. That said, once calibrated, the sealed sensors and automated alignment checks have drastically cut downtime. Lubrication and cleaning are straightforward thanks to the accessible robotic arm joints. Only downside? Spare parts take 7–10 days to ship—hope that improves."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Amina El-Sayed - Custom Fabrication Studio

"I run a one-person workshop specializing in custom ventilation grills, and the BOBO Basic model has been a game-changer. Purchased in September 2024, it fits perfectly in my 40m² space. The 380V power draw is stable on my existing circuit, and the modular clamps let me switch between projects in minutes. I’ve doubled my output without hiring help. For solopreneurs, this machine offers industrial capability at a realistic price."Purchase Date: September 2024 | Usage Period: 10 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Evelyn Reed - Industrial Robotics Consultant

"The BOBO High Speed Radial Wire Welding Machine stands out in mid-tier automation. Its balance of precision (±0.1mm), 380V reliability, and modular design makes it ideal for manufacturers transitioning from manual to automated welding. The Pro Model’s AI-assisted control is particularly impressive—rare at this price point—and delivers measurable efficiency gains in real-world trials."

Markus Feng - Lean Manufacturing Advisor

"After evaluating five welding systems across HVAC and automotive suppliers, I consistently recommend the BOBO Advanced and Pro models. Their rotating table integration and robotic arm coordination reduce idle time by up to 40% compared to traditional setups. For facilities aiming to scale without expanding floor space, this is a strategic investment."

Posted: 2 days ago

"We replaced two manual stations with one BOBO Pro unit. Weld quality is consistent, and the real-time monitoring panel caught a misalignment issue before any scrap was produced. Installation support was excellent—engineer walked us through voltage checks and calibration."

Posted: 1 week ago

"Upgraded from a standard manipulator to the BOBO Advanced model. The 120 RPM rotation speed and full automation have cut our cycle time in half. Integration with our existing PLC system was seamless."

Posted: 3 weeks ago

"The green-painted frame is tough—even survived a minor forklift bump. Only feedback: the touchscreen interface sometimes lags when loading complex programs. Firmware update expected next month, hopeful it resolves this."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.