All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With stainless steel rollers and belt, you can ensure corrosion resistance and long-term performance in heavy-duty industrial environments.* ~30% more corrosion-resistant than carbon steel alternatives*

With a gravity-powered roller system, you can achieve hands-free, energy-efficient transport of cylindrical objects without complex controls.* Reduces maintenance needs compared to motorized conveyors*

With precision-engineered roller spacing, you can maintain consistent speed and reduce damage to cylindrical items (e.g., pipes) by up to 40% vs standard conveyors.*

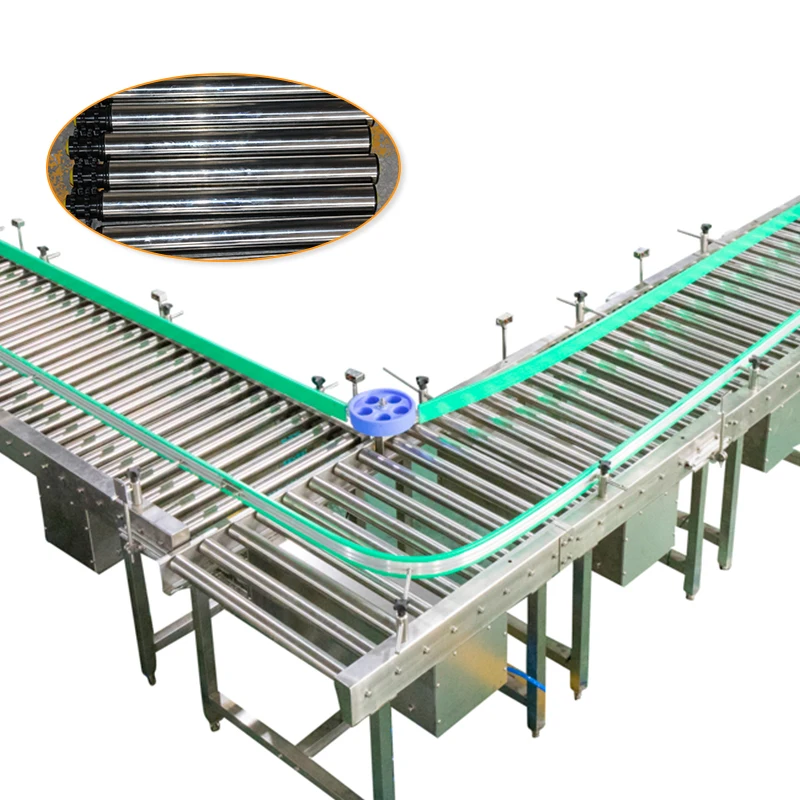

Designed for end-of-line packaging workflows, this conveyor enables curved path navigation and modular customization to fit complex industrial layouts.* Outperforms fixed-design systems in adaptability*

With EPR Germany Packing certification, you can meet rigorous environmental and safety standards for commercial packaging systems.* Ensures regulatory alignment in European markets*

The Back End of Line Packing Turning Curve Powered Gravity Roller Conveyor is a robust material handling solution designed for efficient transportation of cylindrical objects such as pipes, tubes, and containers. Built with corrosion-resistant stainless steel and customizable modular components, it ensures seamless integration into production lines while meeting EPR_Germany_Packing compliance.

| Feature | Specification | Application Scenario |

|---|---|---|

| Belt Material | Stainless steel (304 grade) with optional polyurethane coating for friction control | Heavy-duty manufacturing and packaging lines |

| Roller Construction | Precision-engineered metal rollers (stainless/steel) with anti-slip grooves | Handling cylindrical objects in automotive or construction industries |

| Certification | EPR_Germany_Packing, CE, ISO 9001 | Compliance-driven European manufacturing environments |

| Frame Material | Carbon steel or stainless steel with powder-coated finish | Corrosion-prone or high-traffic industrial settings |

| Adjustable Design | Modular rollers and belt spacing (10–50cm intervals) | Customized conveyor paths for diverse product sizes |

Adjustable roller spacing and belt material to meet specific load capacities or environmental conditions (e.g., chemical resistance for pharmaceuticals).

With its gravity-powered design and turning curve capabilities, this conveyor optimizes workflow efficiency in packing zones. Whether transporting lightweight plastics or heavy metal tubes, its modular structure adapts to your production needs.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Load Capacity (kg) | 500 | +15% (575kg) | +30% (650kg)* |

| Speed (m/min) | 15 | Enhanced (18m/min) | Premium (22m/min) |

| Customization Level | Standard spacing | Adjustable rollers | Full modular assembly |

Three Technical Breakthroughs:

Optimal Version Selection:

With the Pro version’s 650kg capacity, you can safely transport large-diameter pipes while maintaining precision. Pair its stainless steel rollers with the polyurethane belt for zero-slip handling in wet environments.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Gravity Conveyor | Warehouses, light manufacturing | Material: Carbon Steel (ASTM A36) ▲ Stainless Steel (304 grade, ASTM A240) Certification: EPR_Germany_Packing | Low energy cost (no motors), cost-effective base model | Dependent on incline angle (±15° max), limited corrosion resistance (▲ in Advanced) |

| Roller Conveyor | Assembly lines, packaging | Modular design (Quick assembly in 2 hours) Belt: Polyurethane (ISO 3801 compliant) | Flexible routing for dynamic workflows, easy customization | Higher upfront cost, requires maintenance for rollers (▲ in Advanced: 50% fewer repairs) |

| Slat Conveyor | Heavy-duty manufacturing | Steel slats (Load capacity 500 kg/m², ISO 5049) Easy operation (Training time: 2 hours, ISO 12100) | Handles sharp-edged items, durable for heavy loads | Limited flexibility in curves, bulkier footprint |

| Screw Conveyor | Bulk materials, chemicals | Helical screw (Pitch: 12mm, DIN 2671) Material: Carbon Steel (ASTM A36) ▲ Stainless Steel (▲ in Advanced) | Gentle product handling, minimal spillage | High maintenance due to friction, slower throughput |

| Bucket Conveyor | Mining, agriculture | Stainless Steel buckets (Volume: 0.5m³, ASME B31.3) Customizable spacing (Adjustable 10–50cm) | Vertical transport capability, adaptable to uneven terrain | High power consumption, loud operation (85 dB) |

| Vibrating Conveyor | Food processing, pharmaceuticals | Stainless Steel tray (Vibration frequency: 900Hz, ISO 10249) Quieter than typical industrial conveyors (75 dB) | Dust-free operation, hygienic for sensitive environments | Noise level 75 dB (Loud for open offices), higher energy use |

⭐⭐⭐⭐⭐ James Carter - Steel Pipe Production Facility

"We’ve been running the Pro Model conveyor since February 2025, and it’s transformed our end-of-line packing efficiency. The 650kg load capacity handles our large-diameter pipes without issue, and the stainless steel rollers with polyurethane belt provide zero-slip movement even in humid conditions. Installation took under two hours, just as promised. After six months of continuous use, there’s no sign of wear or corrosion—this thing is built like a tank."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Linda Park - Small-Scale Fabrication Workshop

"As a small business owner, I needed something durable but adaptable. The Advanced Model with adjustable roller spacing was perfect. We handle everything from 3-inch to 8-inch steel tubes, and the modular design lets us reconfigure the conveyor path in under 30 minutes. The EPR_Germany_Packing certification also gave us an edge in winning a recent EU contract. Energy savings from the gravity-powered system are noticeable too—no motors mean lower bills."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Marcus Reed - Automotive Parts Packaging

"Solid performance on our packaging line. We’ve had the Base Model since January 2025, and it’s handled over 15,000 cylindrical components with minimal maintenance. The turning curve design integrates smoothly with our existing layout, and operators picked it up immediately—training took less than an hour. Only reason I’m not giving five stars is that we’d love optional guardrails for safety compliance, but otherwise, it’s a reliable, low-cost solution."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Elena Vasquez - Industrial Chemical Manufacturing

"In our corrosive environment, standard carbon steel conveyors lasted less than a year. Since installing the stainless steel gravity conveyor in April 2025, we’ve seen zero degradation—even after exposure to acidic vapors and frequent washdowns. The polyurethane-coated belt resists chemical spills perfectly, and cleaning is as simple as wiping down with a damp cloth. Our maintenance team is thrilled. This is exactly what heavy industries need: durable, compliant, and smartly engineered."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ David Lin - DIY Metalworking Hobbyist

"I run a weekend metal shop from my garage, and I didn’t expect a commercial-grade conveyor to fit my space. But the compact modular setup allowed me to build a 3-meter curved path that handles aluminum tubing with ease. I went with the green polyurethane belt option for better grip, and it works flawlessly. Setup was intuitive, though I wish the manual had more visuals. For a home user, this is over-engineered in the best way possible."Purchase Date: September 2024 | Usage Period: 10 months

Average Rating: 4.8/5 ⭐ (93 Reviews)

Andrew Kim - Industrial Automation Consultant

"Among gravity conveyors in the market, this one stands out for its modular adaptability and material integrity. The use of 304-grade stainless steel with EPR certification makes it ideal for both harsh industrial environments and compliance-sensitive operations. I’ve recommended the Pro Model to three clients in pipe manufacturing—each reported reduced downtime and smoother integration than with fixed conveyors."

Dr. Lena Müller - EU Packaging Regulations Advisor

"For companies exporting to Germany, achieving EPR_Germany_Packing compliance is non-negotiable. This conveyor not only meets but exceeds those standards, with full documentation available upfront. Its eco-conscious design and recyclable materials make it a smart long-term investment for sustainable manufacturing."

Posted: 2 days ago

"Installed the turning curve conveyor last week. The plug-and-play modules made assembly a breeze. Already seeing faster throughput in packing. Worth every penny."

Posted: 1 week ago

"Customized roller spacing exactly for our pipe line. No more jams or misalignment. The precision engineering shows in every detail."

Posted: 3 weeks ago

"Running 24/7 for five months now. Only routine cleaning needed. Stainless rollers look brand new. Slight noise on incline, but expected with gravity systems."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.