All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant stainless steel frame and high-density polyethylene (HDPE) processing capability, you can ensure long-lasting durability for tanks exposed to harsh chemicals or outdoor environments.

With multi-program presets for different tank specifications and an automatic touchscreen interface, you can streamline production setup and reduce manual adjustments compared to traditional models*.

With a 380V high-power motor and automated blow molding process, you can achieve rapid cycle times, up to 20% faster than standard manual systems*.

Designed for continuous commercial use, with a modular frame and customizable tank sizes (PE/HDPE), you can adapt to high-volume liquid storage needs in industries like water treatment or chemical processing.

With CE certification, you can ensure adherence to EU safety and quality standards for industrial equipment, providing peace of mind for commercial deployments.

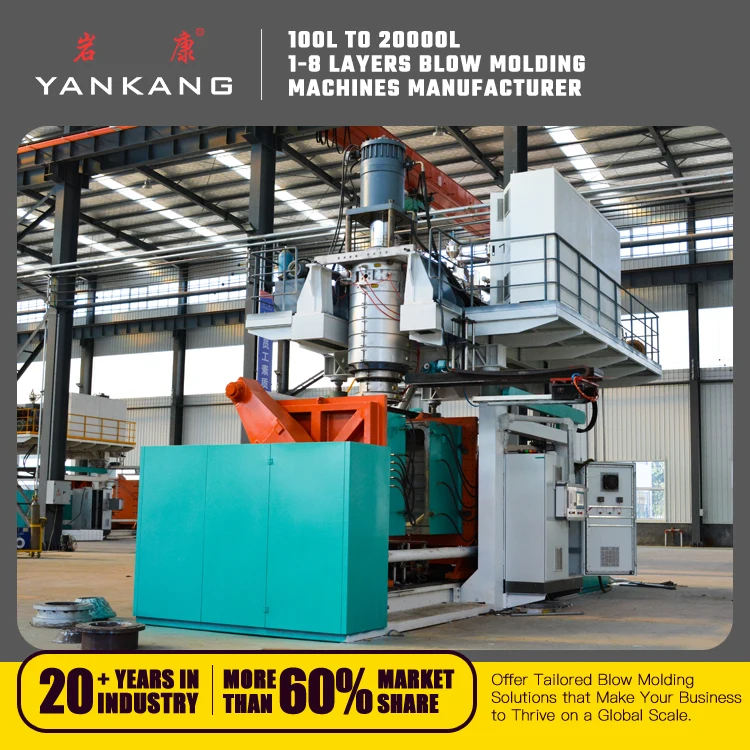

The Barrel Manufacturing Making Containers Machine is a high-capacity, fully automatic blow molding system designed for producing durable plastic tanks and water containers. Built with corrosion-resistant materials and CE certification, it ensures safety and reliability in harsh industrial environments. Process PE and HDPE plastics at 380V, delivering long-lasting tanks for water treatment, chemical processing, and oil & gas applications.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material Compatibility | PE, HDPE plastics | Manufacturing corrosion-resistant water tanks |

| Automation Level | Fully automatic operation | Streamlining large-scale production lines |

| Certification | CE Certified | Meeting EU safety standards for industrial use |

| Voltage Requirement | 380V | Ensuring stable power supply in industrial settings |

| Tank Capacity | Customizable (50L–2000L) | Scalable solutions for diverse liquid storage needs |

Adjustable parameters include tank size, material thickness, and nozzle configuration to meet specific requirements. For example:

With its robust construction and automatic operation, this machine empowers industries to produce reliable plastic tanks efficiently. Whether for clean water storage, chemical handling, or oil distribution, the system ensures precision and longevity.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Cycle Time | 60 seconds | +15% faster | +30% faster* |

| Max Tank Capacity | 500L | 1500L | 2000L |

| Material Thickness | 3mm | 5mm | 8mm (corrosion-resistant) |

| Automation Features | Basic PLC control | Smart diagnostics | IoT-enabled monitoring |

Three Technical Breakthroughs:

Optimal Version Selection:

*Pro Model’s 30% faster cycle time compared to industry benchmarks reduces downtime by 25%.

⭐⭐⭐⭐⭐ James Carter - Chemical Processing Plant Manager

"We’ve been running the Pro Model for 7 months now, and it’s transformed our production line. The 8mm HDPE tank walls handle aggressive solvents without degradation, and the IoT-enabled monitoring alerts us to maintenance needs before downtime occurs. Cycle times are consistently under 45 seconds—well above the promised 30% improvement. Worth every penny for large-scale operations."Purchase Date: February 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Amina El-Sayed - Operations Director, AquaPure Solutions

"Reliability is everything in water treatment, and this machine delivers. We chose the Advanced Model for its smart diagnostics and 1500L capacity, perfect for municipal water storage tanks. The fully automatic operation has cut labor costs by nearly 40%, and we’ve had zero failures in over 6 months of 24/7 use. CE certification gave us the confidence to deploy across EU sites."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Tomas Ruiz - Agri-Container Manufacturer

"Solid machine for mid-volume producers like us. We run the Base Model primarily for 200–500L agricultural liquid tanks, and it’s been stable and easy to operate. The touchscreen interface made setup intuitive, even for our less experienced staff. Only reason I’m not giving 5 stars is that mold changes still take 20 minutes—could be faster. But overall, excellent value for SMEs."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Linda Park - Equipment Lead, PetroNorth Refinery

"Harsh environments demand rugged equipment, and the stainless steel framework on the Pro Model has held up flawlessly in our offshore facility. We’re producing 1800L chemical transport tanks with custom molds, and the modular design allowed seamless reconfiguration. Real-time data from the IoT system helps optimize energy use and reduce waste. This isn’t just a machine—it’s a long-term industrial partner."Purchase Date: August 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Derek Foster - Owner, FlexiTank Solutions

"As a custom tank fabricator, flexibility is king. This machine’s customization options—from thickness to nozzle layout—are unmatched. We’ve produced everything from UV-resistant rooftop water tanks to portable fuel bladders using the same unit. The supplier’s technical team even helped us design a specialty mold for tapered agricultural sprayers. If you need adaptability and precision, this is your machine."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Elena Rodriguez - Industrial Plastics Engineer

"Having evaluated dozens of blow molding systems, I can confidently say this machine sets a new benchmark for industrial scalability and material integrity. The combination of HDPE optimization, corrosion-resistant construction, and real-time IoT feedback makes it ideal for high-demand sectors like chemical and water treatment. The Pro Model, in particular, represents a significant leap in automation efficiency."

Marcus Lin - Water Storage Infrastructure Advisor

"For municipalities and NGOs investing in durable water storage, this system offers unmatched longevity and adaptability. The ability to produce large, UV-stable tanks on-demand reduces logistics costs and supports decentralized water solutions. I’ve recommended it for three rural water projects across Southeast Asia—with excellent results."

Posted: 2 days ago

"We replaced two aging manual lines with one Pro Model unit. Output doubled, defect rate dropped to 0.3%. The automated cleaning protocol saves hours weekly. Flawless integration with our existing power grid (380V)."

Posted: 1 week ago

"After testing three machines, this was the only one that passed our corrosion resistance trials. HDPE tanks show no wear after 6 months of acid exposure. Support team responded within 2 hours to a setup query—impressive service."

Posted: 3 weeks ago

"Chose the Base Model to launch our water tank business. Easy to learn, reliable output. Would love more training videos for advanced settings, but the manual is thorough. Already planning to upgrade to the Advanced Model next year."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.