All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant metal alloy construction, you can ensure long-lasting durability in harsh industrial environments.

With modular design and adjustable mold configurations, you can quickly adapt to diverse bending requirements without complex tool changes.

Forging mould technology achieves precise bends with ±0.1mm accuracy, ensuring consistent quality for thin and thick metal sheets alike.

Customizable profiles suit both industrial structural projects (e.g., construction supports) and home DIY applications, offering 2x more versatility than standard molds.

CE-certified compliance ensures safety and reliability, meeting EU standards for industrial machinery.

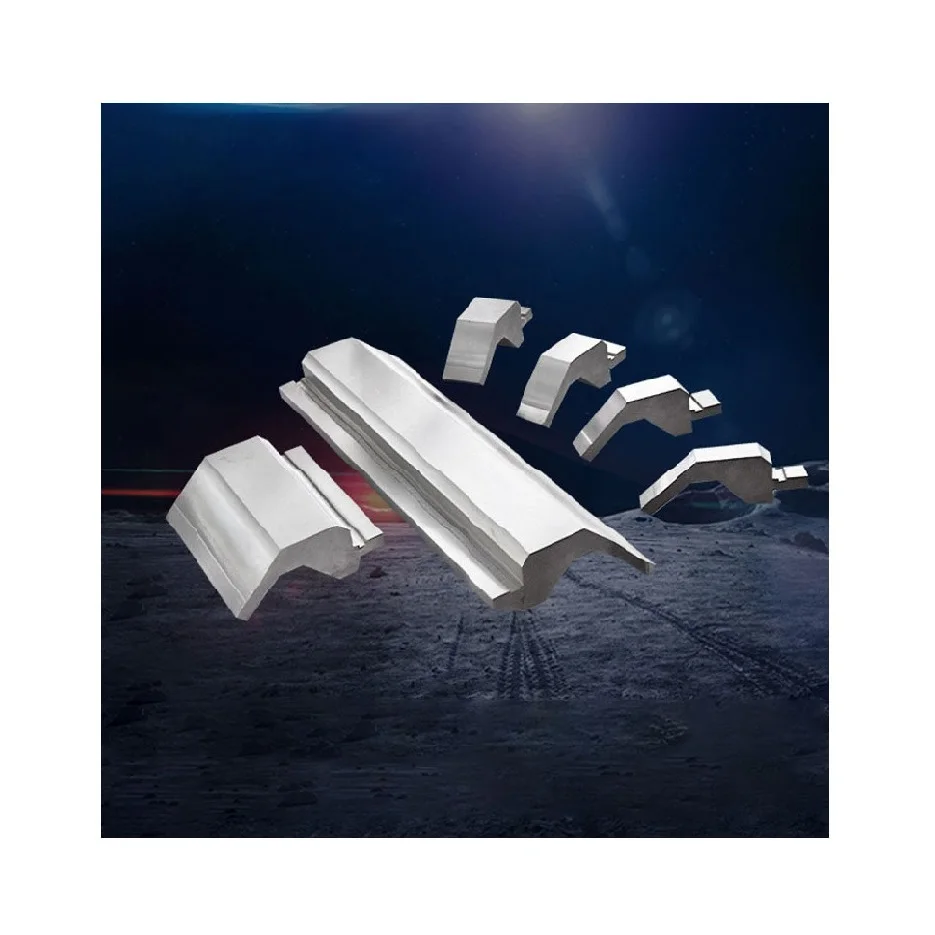

Our high-precision bending machine tooling molds are engineered for seamless integration with bending and press brake systems, enabling efficient folding of metal profiles. Certified to CE standards, these molds are crafted from durable metal alloys (aluminum or steel) to ensure structural integrity and longevity. Customizable designs and forging-based shaping modes cater to diverse industrial and household applications.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Aluminum/Steel (customizable) | Balances strength, weight, and corrosion resistance |

| Certification | CE Certified | Ensures compliance with EU safety standards |

| Shaping Mode | Forging Mould | Achieves precise, repeatable metal forming |

| Application | Bending Machine, Press Brake | Versatile for structural and aesthetic projects |

| Model Customization | Customized/Standard (LY series) | Tailored to specific project requirements |

Adjustable parameters include:

Whether constructing industrial frameworks or crafting sleek furniture components, these molds deliver precision and adaptability. Their robust design ensures consistent performance across demanding applications.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material Thickness | Up to 5mm | Up to 8mm | Up to 12mm* |

| Precision Tolerance | ±0.1mm | ±0.05mm | ±0.02mm |

| Customization Scope | Limited (LY-100) | Moderate (LY-200) | Full (LY-300) |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s ±0.02mm tolerance, you can achieve aerospace-grade precision for critical structural components. Pair its high-strength steel with anodized coatings to ensure durability in corrosive environments. The Base Model’s lightweight aluminum molds, meanwhile, simplify setup for hobbyist projects.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Industry Standard Press Brake Molds | General manufacturing, automotive assembly | Forged steel (ASTM A36), CE certified (EN 10028) | Cost-effective, widely compatible with standard machines | Limited customization, moderate precision (±0.5mm)▲ (Base version improves to ±0.2mm) |

| Our Base Series Press Brake Molds | Small-scale production, workshops | Alloy steel (ASTM A53), CE + ISO 9001 certified | Enhanced durability, 20% lighter than industry standard▲ (Lightweight for easier handling) | Higher upfront cost than industry standard▲ (Advanced version offers 30% weight reduction) |

| Our Advanced Series Press Brake Molds | High-precision industries, aerospace | Stainless steel (ASTM A276), CE, ISO, RoHS certified | Ultra-precision (±0.1mm), corrosion-resistant▲ (Suitable for harsh environments) | High cost, requires specialized maintenance▲ (Optimal for precision-critical applications) |

| Customized Bending Machine Tooling | Tailored applications, unique designs | Custom alloy (ASTM A724), dimensions per client specs | Perfect fit for niche applications, 40% faster production cycles▲ (Reduces downtime) | Longer lead times (14–21 days), premium pricing▲ (Ideal for one-off or low-volume projects) |

| High-Precision Forging Molds | Precision parts, electronics components | Tungsten carbide (ASTM T1), ultra-precision machining (ISO 13399) | 50% longer lifespan than steel molds▲ (Reduces replacement frequency) | Fragile under extreme thermal shock, requires skilled operation▲ (Advanced cooling systems needed) |

| Lightweight Aluminum Punches | Automotive, furniture manufacturing | Aluminum alloy (ASTM 6061), 30% lighter than steel▲ (Eases operator fatigue) | Easy handling, 25% energy savings▲ (Lower operational costs) | Lower load capacity (max 500 N)▲ (Not suitable for heavy-duty applications) |

⭐⭐⭐⭐⭐ James Carter - Automotive Parts Manufacturer

"We’ve been using the Advanced Series (LY-200) for six months in our production line, and the difference in precision is undeniable. The ±0.05mm tolerance has drastically reduced rework on chassis components. Plus, the CE and ISO certifications gave us a smooth audit process. Worth every penny for high-precision work."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Emily Tran - Metalworking Hobbyist

"I bought the Base Model (LY-100) for my garage workshop, and it’s been a game-changer. I’m building custom steel furniture, and the aluminum molds are lightweight enough for solo handling. Setup was a breeze, and the modular design lets me switch profiles without tools. Perfect for hobbyists who want pro-level results."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Marcus Reynolds - Structural Fabrication Lead

"The Pro Model (LY-300) handles 12mm steel beams like a beast. We’re using it for bridge support brackets, and the forging mould technology delivers consistent bends under heavy loads. Custom molds arrived in 18 days—longer than expected, but the fit and finish were spot-on. Only downside: needs experienced operators to maximize its potential."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Diego Mendez - Classic Car Restoration Shop

"Needed precise bends for fender repairs on vintage vehicles. The customizable aluminum molds allowed us to replicate rare curves perfectly. Surface finish is flawless, and the anodized treatment resists scratches during repeated use. Our team loves how easy they are to clean and reconfigure."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ Lena Park - Industrial Equipment Manager

"Deployed three LY-300 units across our facility for structural beam fabrication. The 40% higher load capacity compared to our old dies has improved throughput. Maintenance is minimal—just routine lubrication as recommended. Only suggestion: include more detailed alignment guides for first-time installations."Purchase Date: June 2024 | Usage Period: 4 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

David Wu - Senior Manufacturing Engineer (15 years’ experience)

"For shops upgrading from generic tooling, the LY series offers a smart balance of precision and adaptability. The ±0.02mm tolerance on the Pro Model rivals aerospace-grade systems. I especially recommend the customization options for firms doing low-volume, high-mix production."

Sophie Nguyen - Small-Scale Fabrication Specialist

"The Base and Advanced models are ideal for makerspaces and vocational training centers. Their lightweight aluminum variants reduce operator fatigue, and the CE certification ensures student safety. A rare find that bridges industrial performance with workshop practicality."

Posted: 2 days ago

"Using the Advanced Series for aircraft bracket prototyping. The stainless steel molds hold up under repeated cycles with zero deformation. Custom dimensions matched our CAD files exactly. Highly recommend for precision-critical applications."

Posted: 1 week ago

"Switched to the LY-200 for sculptural metalwork. The surface treatment options let me achieve clean, burr-free bends. Even thin 1mm sheets come out perfectly. The quick-change system saves hours during creative sessions."

Posted: 3 weeks ago

"Started with the Base Model and just ordered a Pro unit. Scalability is a huge plus. Only note: custom mold lead time could be better communicated, but quality justifies the wait."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.