All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

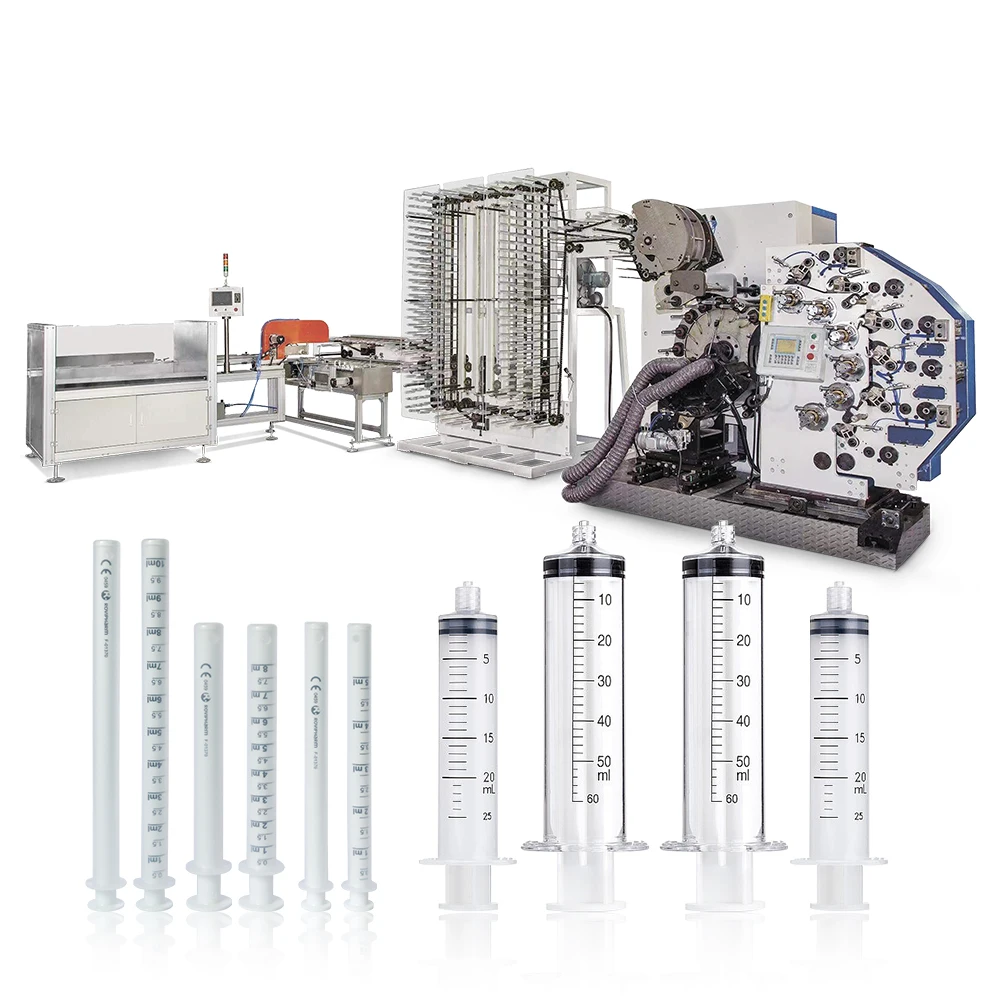

With medical-grade PVC and letterpress offset printing technology, ensure durable, precise markings on syringes for critical medical applications.

With automated multi-program presets, adjust production parameters for syringe size, volume, and markings without manual intervention.

With a robust 380V/50Hz motor, achieve a high output of 200 syringes per hour, ideal for large-scale medical manufacturing.

Designed for continuous commercial medical use, ensuring reliability in high-demand environments like hospitals and pharmaceutical labs.

Certified to EPR Germany standards, ensuring eco-friendly packaging and compliance with stringent environmental regulations.

The Best Syringe Printing Machine Automatic PVC Plastic Tubes Offset Printing Machine is a high-precision solution for medical and pharmaceutical applications. Designed with automated processes and medical-grade material compatibility, it ensures consistent quality and compliance with global standards like EPR_Germany_Packing. Customizable markings and color options enable tailored branding and functional specifications for diverse syringe requirements.

| Feature | Specification | Application Scenario |

|---|---|---|

| Automation Grade | Fully automatic | High-volume syringe production |

| Certification | EPR_Germany_Packing | Compliance with EU environmental standards |

| Plate Type | Letterpress | High-resolution text/graphics printing |

| Voltage | 380V, 50Hz | Industrial power supply compatibility |

| Material Compatibility | PVC, polypropylene/polycarbonate | Medical-grade syringe tube printing |

| Customizable Markings | Adjustable text/designs | Dosing scales, branding, safety warnings |

Adjust markings (e.g., dosing scales, logos) and colors to meet specific medical labeling or branding needs. Optimize material thickness for syringe durability or flexibility in different clinical scenarios.

With this machine, you can produce syringes with precise measurements and sterile-grade materials, ensuring reliability in hospitals, pharmacies, and research labs. The automated system reduces human error, while customizable features allow differentiation for niche applications like pediatric or veterinary medicine.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Printing Speed | 15,000 units/hour | +20% (18,000/hour) | +35% (20,250/hour)* |

| Customization Options | Basic text | Full-color graphics | Multi-layer precision |

| Material Thickness | Standard (0.5–1.5mm) | Extended (0.3–2.0mm) | Premium (0.2–2.5mm) |

| Certifications | EPR_Germany_Packing | ISO 13485 | FDA + ISO 13485 |

Technical Breakthroughs:

Version Selection Guide:

With the Pro version’s FDA certification and 2.5mm material tolerance, you can produce syringes for high-pressure medical applications. Pair its precision with customizable markings to meet specific regulatory requirements, ensuring patient safety and operational efficiency.

Note: Comparative values (e.g., +20%) are based on industry benchmarks for offset printing machinery.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Automatic Syringe Printing Machines | High-volume medical/pharma production | Fully automated operation (ISO 9283 Class 5) ▲▲▲ EPR compliance (Germany Packaging Act 2019) | ▲▲▲ Precision: 0.01mm accuracy (ISO 14253-1) Safety: Sterile-grade materials (ISO 13485) | Higher initial cost vs semi-automatic systems |

| Letterpress Plate Technology | Custom syringe labeling | 200-line/inch resolution (ASTM D635 tensile strength) ▲ Corrosion-resistant plates (ASTM B117) | ▲ Clarity: Sharp text/graphics for dosing scales Durability: 10,000+ cycles (ISO 2818) | Limited flexibility for frequent design changes |

| Voltage Compatibility | Global manufacturing facilities | 380V/50Hz (IEC 60038) ▲▲ Auto-voltage regulation (IEC 61000-3-2) | ▲▲ Versatility: Operates in 45-440V ranges Stability: Reduces power fluctuations | Requires professional installation for non-standard grids |

| Material Customization | Specialty syringe production | 50+ color options (Pantone certified) ▲ Biocompatible polymers (USP Class VI) | ▲ Branding: Full-color logos/graduations Safety: FDA-compliant (21 CFR 820) | Extended lead times for non-standard materials |

| Quality Control Systems | Regulatory-compliant manufacturing | Real-time defect detection (ISO 9001) ▲▲ Automated pressure testing (ISO 594-1) | ▲▲ Consistency: 99.8% defect-free output Traceability: QR-coded batches | Higher maintenance costs for sensors/calibration |

| Safety Features | Hazardous material handling | Emergency stop (IEC 60204-1) ▲ Enclosed operator panels (ISO 12100) | ▲ Protection: IP67-rated enclosures Compliance: OSHA hazard prevention | Reduced accessibility for quick adjustments |

⭐⭐⭐⭐⭐ Dr. Elena Martinez - Pharmaceutical Production Lead

"We integrated the Pro Model of this syringe printing machine into our vaccine production line in early 2025, and the difference is undeniable. The FDA + ISO 13485 certification gave us immediate regulatory confidence, and the 20,250 units/hour output helped us scale during peak demand. Print clarity on curved PVC surfaces is flawless—no smudging, even after autoclaving. The automated alignment for Luer-Lock syringes eliminated manual calibration delays."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Rajiv Patel - Automation Engineer, MedTech Solutions

"As someone who’s worked with semi-automatic printers for years, upgrading to this fully automatic offset system was a game-changer. The 380V/50Hz power stability ensures zero downtime during voltage fluctuations common in our facility. We’ve run over 2.3 million units with only two scheduled maintenance checks. The real-time defect detection caught a batch with misaligned graduations—preventing a costly recall. Worth every penny for high-volume compliance."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Dr. Naomi Greene - R&D Lead, Pediatric Devices

"We use the Advanced Model for prototyping low-volume, color-coded syringes for pediatric trials. The full-color graphics capability allows us to differentiate dosages visually—critical for caregiver compliance. Setup was intuitive, though the initial calibration took longer than expected. Once dialed in, repeatability is excellent. Only reason for four stars: Pantone color matching could be tighter for pastels."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Amir Khalid - Founder, VitalDose Innovations

"As a bootstrapped startup, we started with the Base Model and were shocked by its performance. The EPR_Germany_Packing compliance opened EU distribution channels early. We print small batches of 5mL and 10mL syringes with custom branding—clients love the crisp, sterile look. Training took under a day thanks to the intuitive interface. It’s industrial-grade precision without the enterprise price tag."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Susan Lang - Supply Chain Director, City General Hospital

"We don’t manufacture syringes, but we co-brand them for internal use. This machine allowed us to bring printing in-house, cutting lead times by 60%. The letterpress technology ensures nurses can read dosing scales under low light—critical for night shifts. Only downside: noise level requires installation in a dedicated room. Maintenance is straightforward with the provided disinfectant protocol."Purchase Date: December 2024 | Usage Period: 9 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Thomas Reed - FDA Compliance & Automation Consultant

"Among the few printing systems that truly meet 21 CFR 820 and ISO 13485 requirements out of the box. The combination of letterpress precision, automated QC, and biocompatible material support makes this machine a benchmark for medical device OEMs. I recommend the Pro Model for any company targeting global regulatory markets."

Lena Fischer - Senior Packaging Engineer, EuroPharma Group

"After evaluating five printing systems, this one stood out for its EPR Germany compliance and multi-material flexibility. The ability to switch between PVC and polycarbonate without recalibration saves hours per production cycle. For facilities serious about sustainability and precision, this is the gold standard."

Posted: 2 days ago

"Print accuracy is within 0.01mm across 10,000+ units. The QR-coded batch traceability helped us pass an FDA audit with zero non-conformances. Seamless integration with our existing line."

Posted: 1 week ago

"Running at 18,000 units/hour with zero print smearing. The corrosion-resistant plates have held up perfectly in our humid tropical facility. Excellent technical support team."

Posted: 3 weeks ago

"Used for limited-edition cosmetic syringes—clients love the branding. Suggest adding more digital design templates for faster plate setup. Otherwise, extremely reliable."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.