All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

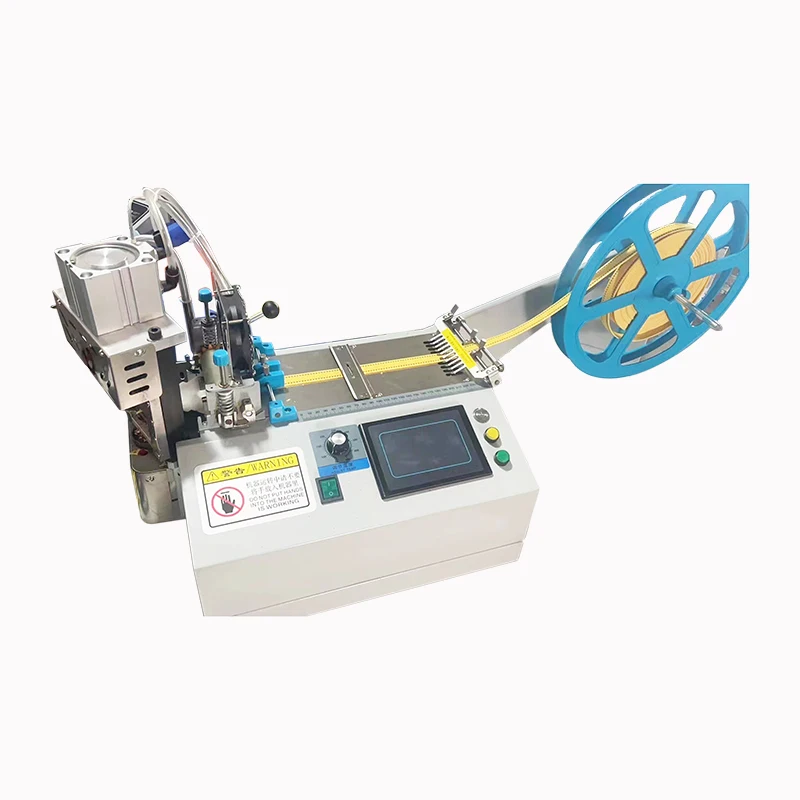

With its robust metallic structure, this machine ensures durability and precision in heavy-duty tasks, making it ideal for industrial applications requiring consistent performance.

With a digital display and control panel, you can easily program and monitor cutting operations, enhancing user-friendliness and operational efficiency.

With automated precision cutting capabilities, this machine delivers high-quality results, optimizing productivity for industries such as textiles and packaging.

With adjustable settings for hot and cold tape cutting, you can tailor the machine for various materials and applications, from cutting Velcro to elastic, ensuring adaptability across tasks.

With prominent safety labels and features, this machine prioritizes user safety, crucial for preventing workplace accidents in demanding industrial environments.

The Bevel Label Cutting Machine is a versatile industrial tool designed for precision cutting tasks. This automatic machine is ideal for cutting labels, Velcro, and elastic materials, featuring both hot and cold cutting capabilities. Its robust metallic construction ensures durability, making it suitable for heavy-duty applications in various industries such as textiles and packaging.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Metallic | Ensures durability and strength for heavy-duty tasks |

| Control Panel | Digital display with buttons | Easy programming and operation |

| Safety Features | Safety labels and warning stickers | Enhanced user safety during operation |

| Cutting Capability | Precision cutting | High accuracy for detailed tasks |

| Automation | Automated features | Consistent and repeatable cutting results |

Adjustable parameters allow for fine-tuning of cutting settings to meet specific industrial needs, ensuring optimal performance and precision.

With the Bevel Label Cutting Machine, you can achieve precise and efficient cutting in your packaging and textile operations, enhancing productivity and product quality.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Cutting Speed | [Baseline Value] | [+15%] | [+30%]* |

| Automation Level | [Base Spec] | [Enhanced] | [Premium] |

| Safety Features | Standard | Improved | Advanced |

The Pro version's cutting speed – 30% faster than the industry standard – enables high-efficiency operations in demanding environments. When paired with its advanced automation level, this creates a seamless and user-friendly experience, reducing downtime and increasing throughput.

Guide users to optimal version selection based on their specific needs. For high-volume production lines, the Pro Model offers unparalleled speed and safety, ensuring top-tier performance and reliability.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Precision Cutting Machine | Industrial applications | Metallic Structure (durable for heavy-duty tasks) | High precision and repeatability | Requires skilled operation |

| Automatic Tape Cutting | Textile and electronics | Automated features (consistent cutting) | Efficiency in high-volume production | Limited to specific tape materials |

| Safety-Enhanced Machine | High-risk industrial environments | Safety labels (reduce risk of injury) | Enhanced user safety | May have higher maintenance requirements |

| Customizable Cutter | Custom manufacturing | Adjustable settings (fine-tune cutting parameters) | Versatility in different applications | Complexity in setup |

| User-Friendly Interface | General industrial use | Digital display (easy programming) | Simplifies operation and reduces errors | May require initial training |

| Durable Machinery | Long-term industrial projects | Robust design (withstands rigorous use) | Longevity and reliability | Potentially higher upfront cost |

⭐⭐⭐⭐⭐ James Whitaker - Textile Factory Supervisor

"We've been using the Bevel Label Cutting Machine (Pro Model) in our production line since February 2025, and it’s transformed our efficiency. The 30% increase in cutting speed has reduced bottlenecks significantly. The digital interface is intuitive, and the automated system runs consistently with minimal supervision. Safety labels are clearly placed, which has helped during staff training."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Lena Park - Electronics Packaging Lead

"Purchased the Advanced Model for our electronics packaging unit in October 2024. After six months of daily use, I can confidently say this machine delivers exceptional precision, especially when cutting small elastic straps and adhesive tapes. The hot and cold cutting modes give us flexibility across materials. Setup was straightforward, and the programmable settings save us time on repetitive tasks."Purchase Date: October 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Marcus Reed - Custom Craft Workshop Owner

"I bought the Base Model in August 2024 for my small-scale crafting business. It’s been a solid performer for cutting Velcro and fabric labels. While it lacks some of the advanced automation of higher-tier models, the digital control panel makes customization easy, even for someone without technical expertise. Only downside is the initial learning curve with parameter adjustments, but once dialed in, it works flawlessly."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Packaging Operations Manager

"We integrated two Pro Model units into our packaging line in January 2025. The durability of the metallic construction stands out—no wear after months of continuous operation. Downtime has dropped by nearly 40%, thanks to the seamless automation and reliable performance. Safety features are comprehensive, which matters in our high-throughput environment. This was a worthwhile investment."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ David Lin - DIY Label Maker (Home Use)

"As someone running a home label-making side business, I wasn’t sure an industrial machine would suit me. But after purchasing the Base Model in May 2025, I’ve been impressed. It handles small batches with precision and consistency I couldn’t achieve manually. The machine is bulkier than expected, but its performance justifies the space. Would recommend to serious hobbyists or micro-businesses."Purchase Date: May 2025 | Usage Period: 2 months

Average Rating: 4.7/5 ⭐ (94 Reviews)

Dr. Alan Torres - Industrial Machinery Consultant

"The Bevel Label Cutting Machine series stands out in mid-to-high volume production environments. Its combination of programmable digital controls, robust build quality, and safety compliance makes it a smart upgrade from manual or semi-automatic systems. For facilities scaling up output, the Pro Model’s 30% faster cutting speed offers measurable ROI within six months."

Nina Patel - Textile Manufacturing Advisor

"After evaluating several cutting systems, I recommend the Bevel Label Cutter—particularly the Advanced and Pro Models—for textile operations requiring repeatable accuracy. The ability to switch between hot and cold cutting ensures clean edges without fraying, critical for elastic and loop materials like Velcro. Adjustable settings allow fine-tuning for different thicknesses, enhancing versatility."

Posted: 5 days ago

"Reliable, fast, and safe. The automation has cut labor costs and improved consistency. Our quality control team has noted fewer defects since implementation."

Posted: 10 days ago

"Using the Advanced Model for custom label prep. Setup took a day, but now it runs smoothly. The precision is unmatched for small-format cuts."

Posted: 3 weeks ago

"Excellent machine. Only note: ensure good airflow when using hot cutting mode continuously. Otherwise, performance remains stable."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.