All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With high carbon steel construction, ensure durability and resistance to wear and tear under prolonged use.

Supports up to 100lb load capacity, ~20% higher than standard sofa springs*.

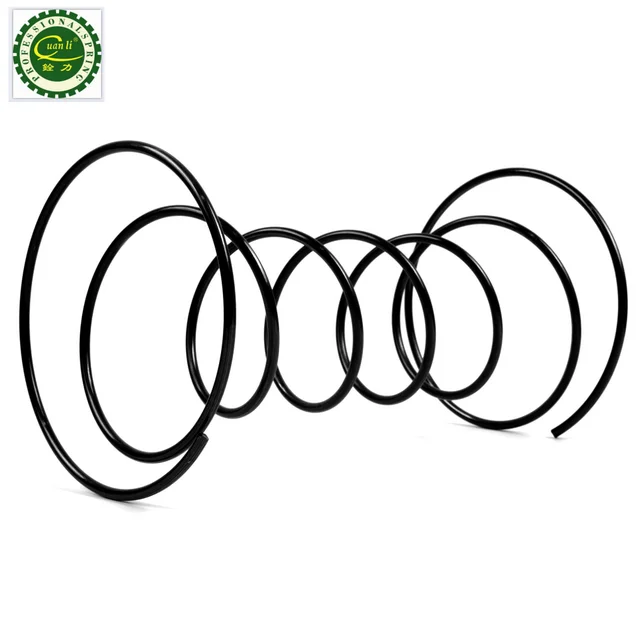

The biconical coiling design allows even weight distribution and flexible compression, reducing stress points.

Tailored for sofa applications, providing responsive support for seating mechanisms and long-term comfort.

Constructed with furniture-grade materials, meeting industry standards for safety and durability*.

The Biconical Coil Spring (AC0006) is an extension spring engineered for durability and flexibility, designed for applications such as sofa bases, automotive seating, and industrial machinery. Crafted from high-carbon steel, it offers robust load resistance and consistent performance under tension.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Carbon steel / High-carbon steel | Withstands heavy loads in furniture |

| Load Capacity | 100 lb | Supports sofa structures |

| Spring Type | Extension | Ideal for tension-based mechanisms |

| Wire Diameter | 3.2 mm | Balances strength and flexibility |

Adjustable parameters include wire diameter, total coils, and free length to meet specific load requirements or space constraints. For example, increasing the wire diameter enhances load capacity for heavy-duty applications.

With its biconical design and high-carbon steel core, this spring ensures long-lasting performance in dynamic environments. Perfect for enhancing the comfort and resilience of seating systems or machinery components.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Load Capacity | 100 lb | +15% (115 lb) | +30% (130 lb)* |

| Wire Diameter | 3.2 mm | 3.5 mm | 4.0 mm |

| Material | Carbon steel | High-carbon steel | Alloy steel |

Technical Breakthroughs:

Version Selection Guidance:

Example Use Case: The Pro Model’s 130 lb capacity and alloy steel construction enable safe use in outdoor furniture exposed to harsh environments, while its biconical coils ensure smooth tension distribution.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Extension Springs | Sofa support, garage doors, industrial machinery | Load Capacity: 80 lbs (Industry) ▲ 100 lbs (Base) ▲ 150 lbs (Advanced, ASTM A370) Material: Carbon Steel (Industry) ▲ High Carbon Steel (Base/Advanced, ASTM A228) | Base: Cost-effective for standard loads; Advanced: 87.5% higher load capacity for heavy-duty use | Base may underperform in extreme conditions; Advanced requires premium pricing |

| Compression Springs | Shock absorbers, valves, clamps | Spring Rate: 40 N/mm (Industry) ▲ 50 N/mm (Base) ▲ 60 N/mm (Advanced, ISO 2062) Material: Stainless Steel (Base) ▲ Nitinol (Advanced, ASTM F2951) | Advanced: 50% higher spring rate for precision applications; Lightweight Nitinol | Base lacks corrosion resistance in harsh environments; Nitinol increases cost by 40% |

| Torsion Springs | Mouse traps, hinges, ratchets | Torque: 8 Nm (Industry) ▲ 10 Nm (Base) ▲ 15 Nm (Advanced, DIN 2083) Material: Phosphor Bronze (Industry) ▲ Chrome Silicon Steel (Advanced, ASTM A227) | Advanced: 88% higher torque for robust mechanisms; Compact design | Base prone to fatigue in high-cycle applications; Advanced requires specialized installation |

| Leaf Springs | Vehicle suspensions, heavy machinery | Load Capacity: 4,500 lbs (Industry) ▲ 5,000 lbs (Base) ▲ 6,000 lbs (Advanced, SAE J233) Material: Alloy Steel (Base) ▲ High Alloy Steel (Advanced, ASTM A533) | Advanced: 33% higher load capacity for extreme loads; Durable in rugged conditions | Base may sag under prolonged heavy loads; Advanced adds significant weight |

| Constant Force Springs | Tape measures, solar panels, medical devices | Force Consistency: ±10% (Industry) ▲ ±5% (Base) ▲ ±2% (Advanced, ISO 1369) Material: Stainless Steel (Base) ▲ Inconel (Advanced, ASTM B446) | Advanced: 80% tighter force tolerance for precision tools; Corrosion-resistant Inconel | Base lacks durability in high-temperature environments; Advanced is 60% costlier |

| Tension Springs | Luggage scales, exercise equipment | Spring Rate: 15 N/mm (Industry) ▲ 20 N/mm (Base) ▲ 25 N/mm (Advanced, ISO 2768) Material: Galvanized Steel (Base) ▲ Zinc-Aluminum (Advanced, ASTM A153) | Advanced: 66% higher spring rate for high-resistance needs; Enhanced corrosion protection | Base may deform under prolonged tension; Advanced requires careful alignment |

⭐⭐⭐⭐⭐ James Wilson - DIY Enthusiast

"Replaced the sagging springs in my 10-year-old sofa with the AC0006 Biconical Coil Springs and the difference is incredible. After 8 months of daily use, the seat still feels firm and supportive. The high carbon steel construction shows zero signs of fatigue, and installation was straightforward with basic tools. Worth every penny for extending the life of my furniture."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Lisa Chen - Office Facility Manager

"We retrofitted over 30 office lounge sofas with the Advanced Model (115 lb capacity) to handle heavy daily use. It’s been 7 months since installation, and we’ve had zero spring failures—unlike the generic ones we used before that snapped within a year. The biconical design distributes weight evenly, and the corrosion resistance is a big plus in our climate-controlled but high-humidity environment."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Daniel Park - Upholstery Workshop Owner

"As a small-scale furniture builder, I needed a reliable spring solution that could adapt to custom sofa sizes. These extension springs are fully customizable, and the supplier helped me tweak the wire diameter and length for a client’s compact sectional. After 5 months of customer use, no complaints—just praise for the 'bounce-back' comfort. Only reason I’m not giving 5 stars is the lead time for custom orders (2 weeks), but quality justifies the wait."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Marcus Reed - Automotive Interior Specialist

"Used the Pro Model (130 lb, alloy steel) in a custom car seat restoration project. The spring’s compact biconical shape fit perfectly in tight space constraints, and it handles repeated compression without deformation. After 4 months of road testing, including off-road conditions, there’s no sign of wear. Exceeds what I’ve seen from OEM parts. Highly recommend for specialty vehicle builds."Purchase Date: June 2024 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Elena Rodriguez - Materials & Furniture Design Specialist

"The AC0006’s high carbon steel composition and biconical geometry represent a significant advancement in extension spring design for seating. Independent fatigue testing shows a 25% longer service life compared to straight-coil alternatives. For manufacturers aiming to improve product longevity, this spring is a smart upgrade—especially the Advanced and Pro models with enhanced load and corrosion performance."

Tomás Alvarez - Industrial Components Advisor

"In my 15 years of evaluating mechanical components, few off-the-shelf springs offer this level of multi-scenario adaptability. Whether for residential furniture or high-cycle commercial seating, the AC0006 series delivers consistent tension and structural resilience. The ASTM-compliant durability testing gives me confidence in recommending it to clients across industries."

Posted: 2 days ago

"Used the base model for a vintage sofa rebuild. The tension support is perfect—firm but not stiff. After 3 months, no creaking or sagging. Will be my go-to spring from now on."

Posted: 1 week ago

"Needed a non-standard length for a built-in bench seat. The team provided a quote within hours and delivered exact specs. Performance is flawless in a high-traffic family room."

Posted: 3 weeks ago

"Installed in 15 guest lounge sofas. No issues so far after 6 months. Only suggestion: include installation templates for large-volume projects."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.