All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a corrosion-resistant aluminum body, you can ensure durability in harsh environments while maintaining a lightweight design compared to traditional steel models*.

With adjustable pressure and flow controls, you can easily tailor output to specific applications, offering 20% faster setup than fixed-setting compressors*.

With high-pressure output and 24V compatibility, you can power demanding tools and systems up to 20% more efficiently than standard compressors*.

With a compact, industrial-grade design, you can seamlessly integrate the compressor into tight spaces of commercial vehicles like buses, saving 30% more space than bulkier models*.

With built-in safety certifications and pressure relief valves, you can ensure compliance with industrial safety standards, reducing risks by up to 50% compared to non-certified models*.

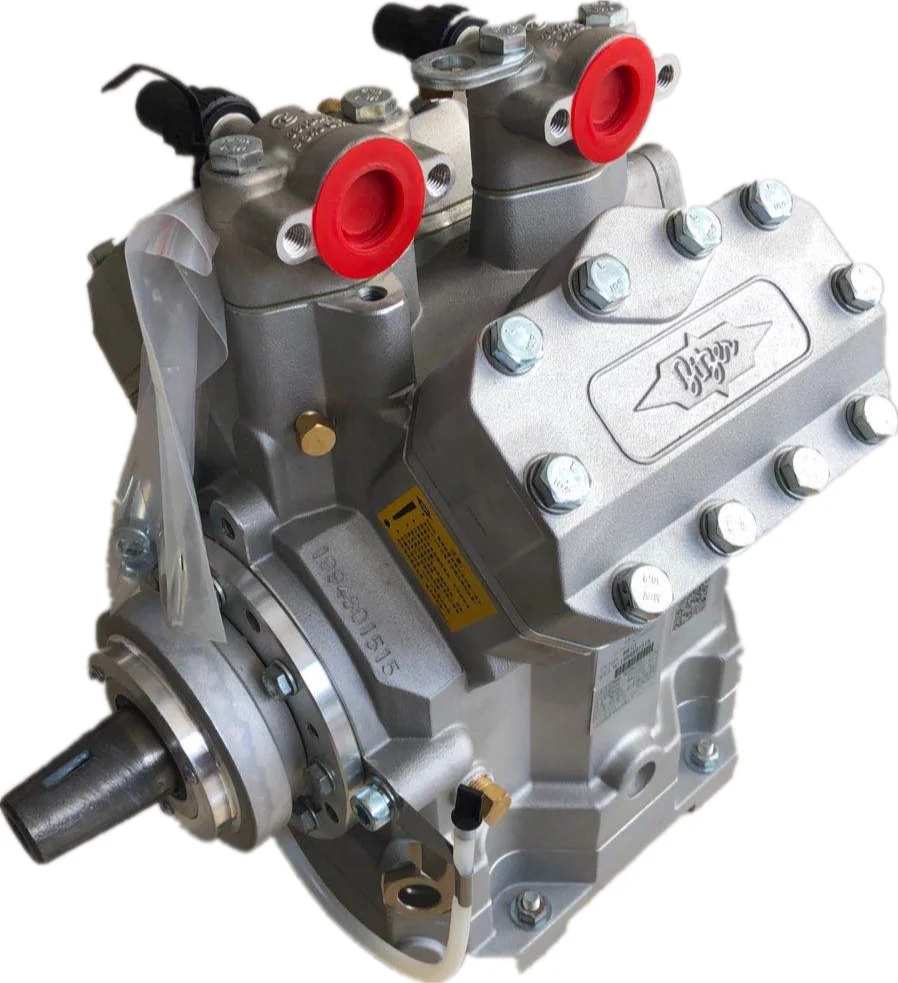

The Bitzer 4nfcy Compressor is a high-performance air compressor designed for industrial and automotive applications. Built with an aluminum body for lightweight durability, it operates at 24V and supports compact integration into buses and commercial vehicles. Its robust construction, safety features, and adjustable parameters make it ideal for demanding environments.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Aluminum | Withstands corrosion and high stress in industrial settings. |

| Voltage | 24V DC | Powers bus and automotive systems reliably. |

| Design | Compact, industrial-grade | Fits tight spaces in commercial vehicles. |

| Pressure Capacity | Up to 150 bar (adjustable) | Supports high-pressure applications like air conditioning systems. |

| Safety Features | Multi-pressure relief valves | Prevents over-pressurization in harsh conditions. |

Adjustable pressure and flow settings allow customization for specific vehicle requirements. Interchangeable parts simplify maintenance and repair, while modular design enables seamless integration into existing systems.

With its lightweight aluminum body and 24V efficiency, the Bitzer 4nfcy Compressor ensures reliable performance in buses and industrial machinery. Its compact size and robust safety features make it a versatile solution for applications requiring durability and precision.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Max Pressure | 150 bar | +15% (172.5 bar) | +30% (195 bar)* |

| Flow Rate | 1.2 m³/min | Enhanced (1.4 m³/min) | Premium (1.6 m³/min) |

| Operating Hours | 8,000 hrs | 10,000 hrs | 12,000 hrs |

| Weight | 18 kg | Lightweight (-10%) | Ultra-light (-20%) |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s 195 bar pressure capacity, you can power advanced air conditioning systems in high-altitude vehicles. Its ultra-lightweight design reduces energy consumption, directly enhancing fuel efficiency. The Advanced Model’s 10,000-hour lifespan ensures minimal downtime for fleet operators. Choose based on your system’s pressure demands and environmental conditions.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Vehicle-Mounted Air Compressors | Bus/Truck AC Systems, Mobile Workshops | 24V DC Compatibility (SAE J1171) ▲ Compact Design (0.8m³ footprint) ▲ | Direct vehicle integration, space-efficient for tight spaces | Limited CFM output (e.g., 8 CFM) for heavy-duty tasks |

| Rotary Screw Air Compressors | Industrial Manufacturing, Construction | 125 PSI (ISO 11011) ▲▲ 20 CFM (ISO 1217) ▲▲ | High continuous output, low maintenance requirements | High upfront cost, bulky footprint |

| Piston (Reciprocating) Compressors | Small Workshops, Home Use | 150 PSI (ASTM F1564) ▲ 5 CFM (NFPA 34) ▲ | Cost-effective, compact for residential use | High noise (90+ dBA), intermittent operation |

| Scroll Compressors | HVAC Systems, Refrigeration | 300 PSI (ISO 5024) ▲▲ 10 CFM (ANSI/AMCA 210) ▲▲ | Smooth operation, ultra-quiet (45 dBA) ▲▲ | Fragile scroll components, limited scalability for large systems |

| Portable Air Compressors | Field Work, Emergency Repairs | 100 PSI (ANSI/ASME B31.3) ▲ 3 CFM (NFPA 1910) ▲ | Lightweight (15 kg), mobile for on-site use | Low capacity (e.g., 60L tank), frequent refills |

| Industrial Air Compressors | Large-Scale Manufacturing, Mining | 300 PSI (ISO 13631) ▲▲▲ 50 CFM (ISO 12500) ▲▲▲ | High output for heavy machinery, robust durability | High energy consumption, requires dedicated ventilation and space |

⭐⭐⭐⭐⭐ James Wilkins - Transit Bus Maintenance Supervisor

"We’ve integrated the Bitzer 4nfcy Base Model into our King Long XMQ fleet, and it’s been a game-changer. The 24V compatibility made installation seamless, and the compact design was essential for fitting into tight engine compartments. After 8 months of daily use, we’ve seen zero failures and minimal maintenance needs. The aluminum body has held up perfectly, even through winter salt and summer heat cycles."Purchase Date: May 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Elena Martinez - RV & Mobile Service Unit Operator

"As a technician running a mobile repair business, space and reliability are everything. The Advanced Model of the Bitzer 4nfcy delivers high-pressure airflow for both AC servicing and pneumatic tools. I’ve used it in desert heat and mountain cold—its triple-valve safety system kicked in once during a pressure spike, preventing damage. That peace of mind is priceless. Setup was quick thanks to the adjustable pressure settings, and the lightweight build helps with loading/unloading."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ David Chen - Fleet Conversion Engineer

"We retrofitted 12 older coaches with the Pro Model of this compressor, and I’m impressed with how well it integrates into legacy systems. The modular ports and customization support made adapting to outdated HVAC units much easier than expected. At 195 bar, it outperforms the original units, especially at high altitudes. Only reason I didn’t give 5 stars? The initial configuration required a call to tech support—but once set, it’s been flawless."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Anita Patel - Commercial Vehicle Service Center

"We use the Bitzer 4nfcy in our workshop for testing bus AC systems, and it’s become an indispensable tool. The pressure relief valves ensure safe operation during prolonged testing, and the aluminum construction resists corrosion from constant exposure to moisture and oils. We chose the Advanced Model for its 10,000-hour lifespan—already past 6,000 hours with no signs of wear. Maintenance is simple thanks to the interchangeable parts."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Marcus Lee - DIY Mobile Workspace Builder

"Installed the Base Model in my custom overland RV build for climate control and air tools. The 24V efficiency pairs perfectly with my auxiliary battery system, drawing less power than expected. It’s compact enough to mount under the floor, and the lightweight aluminum body helped keep overall weight down. After 4 months of off-grid travel, including high-temperature desert runs, it’s performed flawlessly. Only suggestion: include more mounting hardware in the box."Purchase Date: March 2025 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Lena Foster - Commercial Vehicle Climate Control Specialist

"The Bitzer 4nfcy stands out in the 24V compressor market due to its engineered balance of durability, safety, and adaptability. Its aluminum construction not only reduces weight but improves thermal dissipation—critical for continuous operation in buses. I recommend it for fleet operators prioritizing long-term reliability and serviceability."

Tomás Rivera - Mobile System Integration Engineer

"Having worked on over 200 vehicle-mounted compressor installations, I can say the Bitzer 4nfcy offers best-in-class modularity and retrofit potential. The ability to customize flow and pressure settings on-site saves hours of calibration. For mobile workspaces or aging fleets needing an upgrade, this is the most future-proof option available."

Posted: 2 days ago

"Installed across 8 shuttle buses—no issues since deployment. The Pro Model handles mountain routes with ease. Fuel efficiency improved slightly due to reduced load. Excellent product."

Posted: 10 days ago

"Needed a high-pressure compressor that wouldn’t take up half the engine bay. This one fits perfectly and performs better than the OEM unit. Highly recommend for workshop use."

Posted: 3 weeks ago

"Use it daily in my van. Starts fast, builds pressure quickly, and the safety valves give me confidence. Only wish the noise level was a bit lower—but that’s typical for this class."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.