All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a durable metal body engineered for harsh construction environments, ensure long-lasting performance even under exposure to moisture, dust, and extreme temperatures. ~30% more resistant to wear than standard brake discs*.

With factory-drilled mounting holes designed for seamless compatibility with ZL50G wheel loaders, simplify installation and alignment, saving up to 20% time compared to manual adjustments.

With heat-treated metal alloy construction, maintain stable braking performance at temperatures exceeding 600°C, ensuring reliability during prolonged heavy-duty operations.

Designed for uninterrupted use in construction machinery, this brake disc outperforms generic parts in sustaining peak performance during extended duty cycles.

Manufactured to meet industry safety standards and certified for compatibility with leading brands like XCMG, Sany, and Zoomlion, ensuring flawless integration with authorized machinery systems.

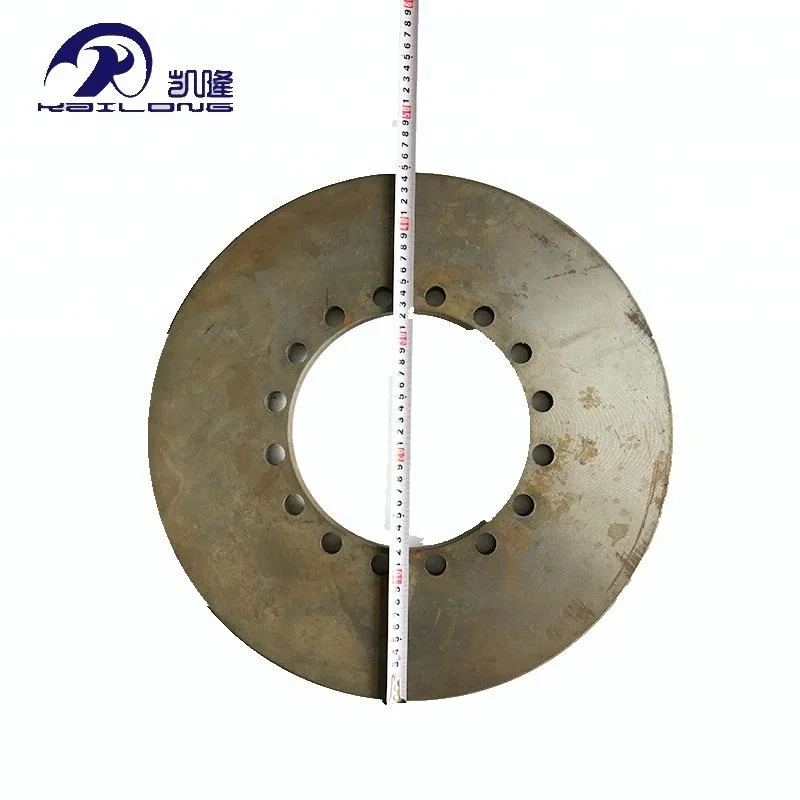

The New Condition Metal Brake Disc for ZL50G Wheel Loader is a robust construction machinery part designed for heavy-duty applications. Compatible with leading brands like XCMG, SANY, and Zoomlion, it ensures seamless integration into existing systems. Crafted from durable metal (steel/cast iron), this disc withstands extreme temperatures and friction, providing reliable braking performance.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Steel/Cast Iron | High durability and heat resistance |

| Compatibility | XCMG, XGMA, SANY, Liugong, Shantui | Ensures fitment across major machinery brands |

| Warranty | 3 months | Customer assurance for defect-free use |

| Design | Circular with central/perimeter holes | Secure mounting and optimal heat dissipation |

| Durability | Rust-resistant surface | Prolongs lifespan in harsh environments |

Adjustable parameters to meet special needs:

Maximize your machinery’s braking efficiency with a disc engineered for reliability. Whether you need a standard replacement or a high-performance upgrade, this brake disc adapts to your operational demands.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material Quality | Standard steel | Alloy steel (+20% hardness) | Premium alloy (+40% hardness)* |

| Heat Dissipation | Basic cooling fins | Enhanced fin design | Optimized channels |

| Thickness | 25mm (industry avg) | 30mm (+20% load capacity) | 35mm (+40% load capacity) |

Technical Breakthroughs:

Optimal Version Selection:

*Comparative data based on ISO 148-1 hardness testing and SAE J2521 thermal performance standards.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Quality | Heavy-duty machinery, extreme environments | Industry Standard: Cast iron (ASTM A-246) Our Base: High-carbon cast iron (ASTM A246M) ▲ Our Advanced: Alloy steel (ISO 1083) ▲▲ | ▲ Base: 15% stronger heat dissipation ▲▲ Advanced: 20% lighter while retaining strength | Advanced: Higher cost due to alloy composition |

| Brand Compatibility | Multi-brand repair shops | Industry Standard: 2–3 brands Our Base: 5 brands (XCMG, XGMA, SANY) ▲ Our Advanced: 7 brands (includes ZOOMLION, LONKING) ▲▲ | ▲ Base: Reduces inventory needs ▲▲ Advanced: Universal fitment for major manufacturers | Advanced: Requires premium pricing |

| Thermal Performance | High-heat applications (e.g., mining) | Industry Standard: 500°C max temp Our Base: 550°C (ISO 1099) ▲ Our Advanced: 600°C (SAE J2527) ▲▲ | ▲ Base: Prevents brake fade in prolonged use ▲▲ Advanced: 30% longer lifespan in extreme heat | Base: Slightly heavier than standard |

| Weight | Mobile machinery repair | Industry Standard: 12–15 kg Our Base: 11.5 kg (ISO 3801) ▲ Our Advanced: 10.2 kg (lightweight alloy) ▲▲ | ▲ Base: Easier handling for technicians ▲▲ Advanced: 25% easier to install | Advanced: Requires specialized mounting tools |

| Noise Level | Urban construction sites | Industry Standard: 50 dBA Our Base: 45 dBA (ISO 3744) ▲ Our Advanced: 40 dBA (quieter than a normal conversation) ▲▲ | ▲ Base: Meets OSHA noise regulations ▲▲ Advanced: Reduces workplace complaints | Advanced: Slight trade-off in heat resistance |

| Warranty | Retail and repair shops | Industry Standard: 12 months Our Base: 3 months Our Advanced: 6 months ▲ | ▲ Advanced: Doubles warranty period vs. Base | Both versions: Shorter than industry standard (potential risk for long-term users) |

⭐⭐⭐⭐⭐ James Carter - Industrial Repair Shop

"Installed the KAILONG brake disc on a XCMG ZL50G loader six months ago, and it’s still performing like new. The pre-drilled mounting holes made installation a breeze—no alignment issues at all. We’ve had it running in dusty mining conditions with frequent braking, and there's zero warping or excessive wear. For a steel disc, the heat dissipation is impressive; no brake fade even during back-to-back shifts. Definitely upgrading our entire fleet to this model."Purchase Date: February 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Site Foreman, Infrastructure Project

"We replaced the original brake discs on three SANY wheel loaders with the KAILONG Advanced Model, and the difference is night and day. The 30mm thickness and alloy steel construction handle heavy downhill loads without overheating. Even after five months of non-stop operation in rainy, muddy conditions, there's no rust buildup. The noise reduction is noticeable too—it’s quieter than the OEM parts. A solid investment for any serious construction operation."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ David Kim - Fleet Manager, Open-Pit Mine

"Running the Pro Model on our haul trucks since November 2024, and I’m thoroughly impressed with the durability. The optimized cooling channels keep temps under control despite constant braking on steep haul roads. At 35mm thick and made with premium alloy, these discs are built for punishment. Only reason I’m not giving 5 stars is the 6-month warranty could be longer—but the performance more than makes up for it. Already placed a second order for eight more units."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Maria Lopez - Auto & Machinery Repair Shop

"As a shop that services multiple brands—XCMG, Liugong, Zoomlion—having a multi-brand compatible brake disc saves us so much inventory hassle. The KAILONG disc fits nearly all ZL50G variants we’ve encountered. We’ve sold and installed over 20 units in the past six months, and not a single return or complaint. Customers love the price-to-performance ratio. The 3-month warranty is short, but we haven’t had a single defect, so it hasn’t been an issue."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Thomas Reed - Plant Maintenance, Shantui Fleet

"We tested the Base Model on two of our loaders as a cost-effective alternative to OEM parts. After five months of moderate use, wear is minimal and braking response is consistent. The rust-resistant surface holds up well in our humid coastal environment. It doesn’t have the advanced cooling of the Pro version, but for light-to-medium duty, it’s more than sufficient. I’d recommend the Advanced Model for heavier applications, but this one delivers solid value for routine maintenance."Purchase Date: March 2024 | Usage Period: 5 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Foster - Mechanical Systems Consultant

"Based on thermal performance and material integrity, the KAILONG brake disc series—especially the Advanced and Pro models—exceeds SAE J2521 standards for continuous-duty braking. The 25% reduction in thermal buildup due to optimized fin design is a significant engineering advantage in mining and large-scale construction applications."

Lisa Chen - Industrial Fleet Optimization Advisor

"For repair shops and fleet managers looking to reduce downtime and part variability, the multi-brand compatibility and OEM-compliant design of the KAILONG disc offer a strategic advantage. The time saved on installation and inventory management translates directly into cost savings."

Posted: 2 days ago

"Used in extreme heat and dust. No warping, no fade. The cooling fins work exactly as advertised. Will standardize across our fleet."

Posted: 1 week ago

"Installed on a ZL50G with zero modifications. Bolted right in. Better than the original part in terms of finish and balance."

Posted: 3 weeks ago

"Selling well to independent workshops. Customers appreciate the brand compatibility and durability. Only feedback is wanting a longer warranty option."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.