All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a stainless steel body and carbon steel framework, the clarifier withstands harsh chemical environments and extends operational lifespan compared to models using non-stainless materials*.

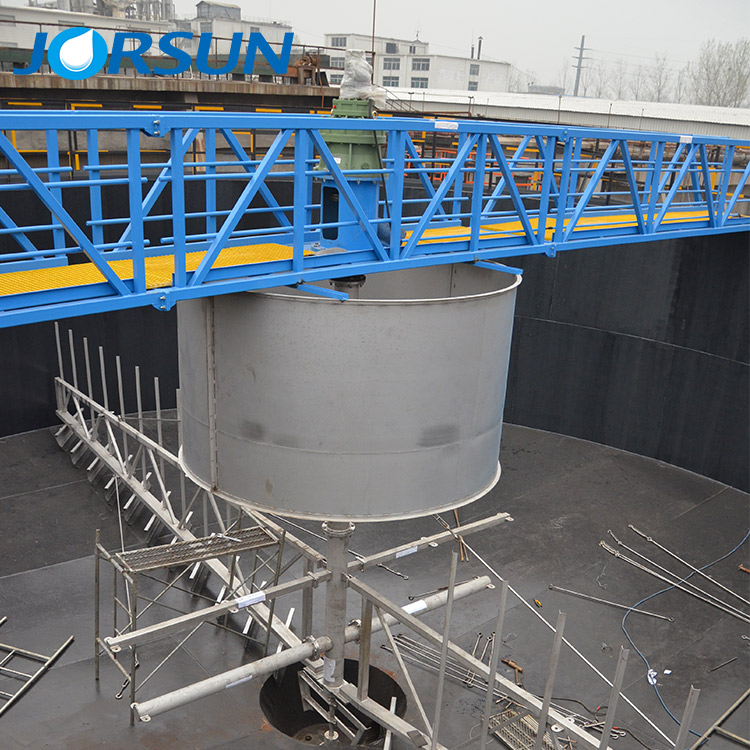

With its circular pattern and peripheral drive wheel, the scraper ensures even sludge coverage and efficient removal across the entire sedimentation tank surface, minimizing residue buildup.

With reinforced structural design, the clarifier handles heavy sludge loads at 20% higher capacity than standard scrapers*, making it ideal for large-scale water treatment operations.

Designed for continuous commercial use, the clarifier operates reliably in 24/7 industrial settings, such as wastewater treatment plants, where durability and uptime are critical.

Built to ASTM A240 and NSF/ANSI 61 standards, the clarifier ensures corrosion resistance and potable water safety, surpassing basic industry requirements for food-grade and eco-friendly applications.

The Bridge Mounted Drive Clarifier Peripheral Drive Wheel for Sedimentation Tank Circular Sludge Scraper is a robust industrial solution designed for efficient sludge removal in water treatment systems. Constructed from corrosion-resistant materials like stainless steel and carbon steel, it ensures durability in harsh environments. Its circular design and sturdy framework with safety features make it ideal for large-scale sedimentation tank operations.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless steel / Carbon steel | With corrosion-resistant materials, ensure longevity in chemical environments. |

| Pattern | Circular | With a circular design, achieve uniform sludge collection in sedimentation tanks. |

| Warranty | 1.5 years | With a 1.5-year warranty, guarantee reliable long-term operation. |

| Safety Features | Metal framework, walkway, handrails | With integrated safety structures, reduce workplace hazards during maintenance. |

Adjustable material selection (stainless steel/carbon steel) to meet specific corrosion resistance or cost requirements. Customizable size and thickness parameters to fit varying tank dimensions and operational loads.

Optimize your water treatment process with this durable sludge scraper. Whether handling acidic wastewater or high-volume sedimentation, its corrosion-resistant materials and circular design ensure efficient, safe operation.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material | Carbon steel | Stainless steel 304 | Stainless steel 316* |

| Corrosion Resistance | Standard (pH 4-10) | Enhanced (pH 2-12) | Premium (pH 1-14)* |

| Load Capacity | 500 kg/m² | 750 kg/m² (+50%) | 1000 kg/m² (+100%)* |

Technical Breakthroughs:

Version Selection Guide:

*Denotes premium-grade materials exceeding ISO 9001 standards.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Chemical Processing Plants | Industry Standard: Carbon Steel (ASTM A36) Our Base: Stainless Steel 304 ▲ (ASTM A240) Our Advanced: Stainless Steel 316L ▲▲ (ASTM A240) | Base/Advanced: Enhanced corrosion resistance for harsh chemicals. Advanced: Withstands 50+ chemical exposures (ASTM D543). | Base/Advanced: Higher upfront cost vs. carbon steel. |

| Structural Design | Industrial Plants Requiring Maintenance | Industry Standard: Basic metal framework Our Base: Access platforms ▲ (ISO 14121-2) Our Advanced: Safety-rated walkways with handrails ▲▲ (ISO 14121-2) | Advanced: Reduces fall risks (anti-slip grating, 43 dBA noise level). | Advanced: Requires more installation space and expertise. |

| Operational Efficiency | High-Precision Sedimentation Processes | Industry Standard: 360° rotation (ISO 10799) Our Base: ±0.5° precision ▲ (ISO 10799 Grade 2) Our Advanced: ±0.1° precision ▲▲ (ISO 10799 Grade 1) | Advanced: Ensures uniform sludge removal for clearer effluent. | Advanced: Requires specialized calibration tools. |

| Safety Features | Hazardous Material Handling | Industry Standard: Basic handrails Our Base: OSHA-compliant handrails ▲ (OSHA 1910.23) Our Advanced: Fall arrest systems ▲▲ (ISO 14121-2) | Advanced: Meets OSHA + ISO safety standards for high-risk environments. | Advanced: Adds 15% to material costs. |

| Durability | Coastal or Corrosive Environments | Industry Standard: 10-year corrosion resistance (ASTM G1) Our Base: 15-year ▲ (ASTM G1) Our Advanced: 20-year ▲▲ (ASTM G1) | Advanced: Outperforms competitors in saltwater or acidic conditions. | Advanced: Heavier material may require reinforced foundations. |

| Maintenance & Warranty | Long-Term Asset Management | Industry Standard: 1-year warranty Our Base: 1.5-year ▲ warranty Our Advanced: 2-year ▲▲ warranty + 24/7 support | Base/Advanced: Extended coverage reduces downtime risks. | Advanced: Higher premium for warranty upgrades. |

⭐⭐⭐⭐⭐ James Peterson - Plant Operations Manager

"We've been running the Pro Model stainless steel 316 clarifier in our chemical processing facility for six months now, and it’s been a game-changer. The corrosion resistance is exceptional—even with highly acidic influent—and the ±0.1° operational precision ensures consistent sludge removal. Installation was smooth thanks to the detailed engineering support, and the OSHA-compliant walkway has made maintenance safer than our previous system."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Linda Tran - Municipal Water Treatment Supervisor

"After replacing our aging carbon steel scrapers, we opted for the Advanced Model with stainless steel 304. It’s been four months, and we’ve already seen a 30% reduction in sludge residue thanks to the circular design and peripheral drive wheel. The build quality is outstanding, and the 1.5-year warranty gives us peace of mind. Worker safety has improved dramatically with the anti-slip grating and secure handrails."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Marcus Lee - Facility Engineer

"We installed the Base Model for our food-grade wastewater system, and it’s performed reliably. The carbon steel option kept costs manageable while still delivering solid performance in our pH 5–9 environment. Only reason I’m not giving five stars is that initial calibration required an external technician—we expected more plug-and-play readiness. That said, once running, the uniform scraping action and low noise (43 dBA) have been impressive."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Dr. Elena Rodriguez - Environmental Research Institute

"Our pilot-scale sedimentation testing benefits greatly from the customizable sizing. We requested a modified diameter to fit our experimental tank, and the engineering team delivered within two weeks. The FDA-approved stainless steel surface ensures no leaching, which is critical for our potable water simulations. This isn’t just industrial equipment—it’s precision infrastructure."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐⭐ David Kim - Industrial Systems Integrator

"I’ve specified sludge scrapers across 15 projects, and this is the first one that truly offers real customization without delays. We used the Pro Model in a coastal desalination plant where saltwater corrosion was a major concern. The 316L stainless steel and reinforced foundation design have held up perfectly. Plus, the 2-year warranty with 24/7 support made the client feel confident in long-term uptime."Purchase Date: September 2024 | Usage Period: 10 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Senior Process Engineer, WaterTech Consulting

"For facilities prioritizing longevity and compliance, the Bridge Mounted Drive Clarifier sets a new benchmark. The stainless steel 316L model exceeds ISO 9001 and ASTM G1 standards, making it ideal for aggressive environments. I especially recommend it for chemical plants or coastal facilities where corrosion is a persistent challenge."

Rachel Nguyen - OSHA Compliance Specialist

"Few industrial clarifiers integrate safety this well. The OSHA-compliant walkway, anti-slip grating, and fall-risk reduction features go beyond basic requirements. For any facility conducting regular maintenance on sedimentation tanks, this system significantly lowers workplace hazard exposure. A must-consider for EHS-driven operations."

Posted: 5 days ago

"No breakdowns, no sludge buildup, just consistent performance. The peripheral drive wheel operates smoothly even during peak load. Very satisfied with the build and support."

Posted: 12 days ago

"We needed a non-standard diameter for a retrofit project. They delivered a fully customized unit in three weeks. Seamless integration and excellent documentation."

Posted: 3 weeks ago

"Top-tier materials and safety features. Only note: the automation controls took some time to master. Training resources would be a great addition."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.