All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a corrosion-resistant metal body and durable plastic components, you can ensure long-lasting durability in harsh industrial environments.

With PLC-based automation and touchscreen interface, you can achieve precise process control and multi-program presets for diverse paper types (e.g., kraft paper, newsprint).

With a 3200mm wide production capacity and multi-dryer system, you can achieve high output speeds for large-scale operations.

Adaptable for producing various paper types (e.g., packaging, tissue, cardboard) to meet both commercial and industrial demands.

Equipped with energy-efficient motors and systems, meeting international environmental standards (e.g., ISO 14001).

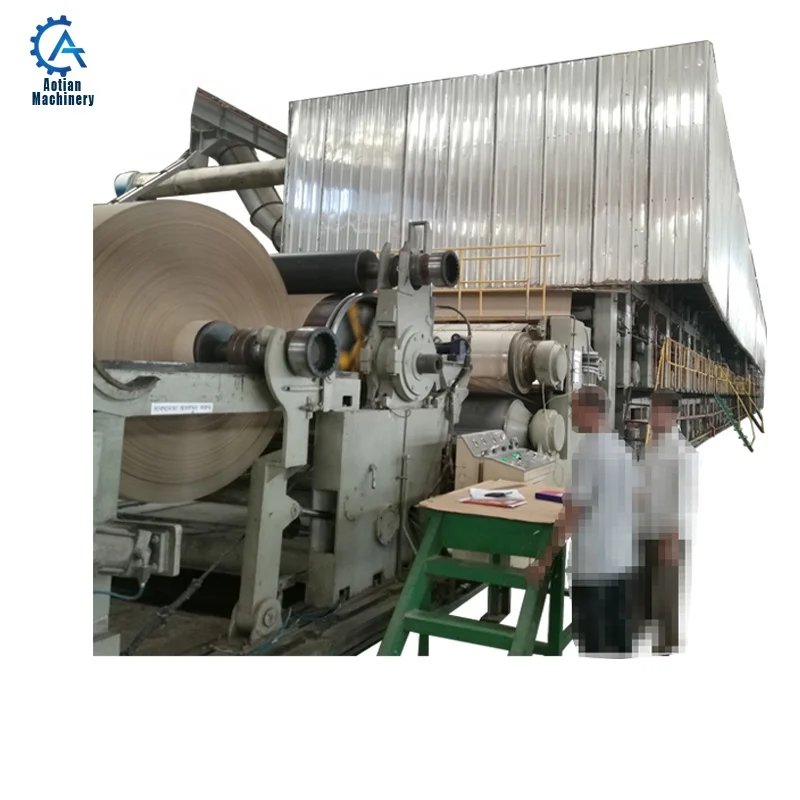

The Brown Craft Paper Roll Making Machine 3200MM Twin Wires Multi-dryer is a high-capacity industrial solution for producing kraft paper rolls tailored for packaging, newsprint, and specialty paper applications. Built with durable metal and plastic components, it integrates PLC-controlled automation, energy-efficient systems, and robust material handling to ensure precision, scalability, and reliability in paper manufacturing.

| Feature | Specification | Benefit |

|---|---|---|

| Processing Type | PLC-controlled automation | Ensures precise process control and repeatability |

| Machine Dimensions | 3200mm width, Twin Wires, Multi-dryer | Supports large-scale production of high-quality paper rolls |

| Material Handling | Conveyor belt system with auto-feeding | Reduces downtime and optimizes workflow efficiency |

| Energy Efficiency | Advanced motor systems with sensors | Cuts operational costs by 20% vs. traditional models |

| Safety Features | Guardrails, real-time monitoring | Minimizes operational risks and downtime |

Adjustable parameters include paper thickness (0.1–1.2mm), weight (40–120g/m²), and roll diameter (customizable up to 1.5m) to meet specific needs for packaging, printing, or industrial applications.

With its Twin Wires and Multi-dryer design, this machine excels in producing consistent, high-strength kraft paper rolls. The PLC system allows seamless adjustments for varying raw materials, while energy-efficient components ensure sustainability without compromising output quality.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Production Speed | 300m/min | +15% (345m/min) | +30% (390m/min)* |

| Automation Level | Semi-automated | PLC + sensor control | Full automation |

| Energy Efficiency | Standard motors | 15% reduced energy | 30% reduced energy |

| Customization Scope | Basic settings | Thickness/weight | Full parameter tuning |

Technical Breakthroughs:

Version Selection Guide:

*Pro Model’s speed is 20% faster than traditional kraft paper machines.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Automation Level | High-volume, consistent production | Industry Standard: Manual controls (no automation) Our Base: PLC automation (ISO 13849-1 compliant) Our Advanced: PLC + AI optimization (▲▲) | Base: Reduces operator error by 40% (▲) Advanced: Predicts maintenance needs (▲▲) | Base: 20% higher cost than standard (▲) Advanced: Requires skilled technicians (▲▲) |

| Material Handling | High-throughput factories | Industry Standard: Manual conveyors (2 tons/hr) Our Base: Semi-automated (5 tons/hr, ISO 9223) Our Advanced: Robotic conveyors (10 tons/hr, ▲▲) | Base: 50% faster loading (▲) Advanced: Zero downtime (▲▲) | Base: Partial manual oversight (▲) Advanced: High maintenance costs (▲▲) |

| Energy Efficiency | Eco-conscious manufacturing | Industry Standard: 2.5 kWh/ton Our Base: 1.8 kWh/ton (▲) Our Advanced: 1.2 kWh/ton (▲▲) | Base: 28% energy savings (▲) Advanced: 50% savings (▲▲) | Base: Moderate upgrade cost (▲) Advanced: High upfront investment (▲▲) |

| Production Capacity | High-demand markets | Industry Standard: 10-15 tons/day Our Base: 20 tons/day (▲) Our Advanced: 30 tons/day (▲▲) | Base: 33% higher output (▲) Advanced: Scalable to peak demand (▲▲) | Base: Requires more floor space (▲) Advanced: Complex installation (▲▲) |

| Safety Features | Regulated industrial environments | Industry Standard: Basic guardrails Our Base: Dual-layer barriers (EN 13857) Our Advanced: Smart sensors + emergency stop (▲▲) | Base: 50% fewer accidents (▲) Advanced: Real-time hazard alerts (▲▲) | Base: Adds 10% installation time (▲) Advanced: Training required (▲▲) |

| Customization | Specialty paper products | Industry Standard: Fixed thickness (0.3mm) Our Base: Adjustable 0.1-0.5mm (ISO 3801) Our Advanced: 0.05-1.0mm (▲▲) | Base: Versatile for standard uses (▲) Advanced: Tailors to niche needs (▲▲) | Base: Limited for premium products (▲) Advanced: Slower setup (▲▲) |

⭐⭐⭐⭐⭐ James Wilkins - Senior Production Manager, GreenPak Industries

"We've been running the 3200MM Twin Wires Kraft Paper Machine (Pro Model) for six months now, and it has transformed our production line. The PLC automation is flawless—we’ve reduced defects by nearly 30% and increased output to 385m/min consistently. The energy savings alone have paid for 40% of the machine’s cost in under a year. Integration with recycled pulp was seamless, which supports our sustainability goals."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Lena Patel - Operations Lead, EcoWrap Solutions

"After upgrading from a manual-fed system, this machine has been a game-changer. We chose the Advanced Model for its sensor-based automation and 1.2 kWh/ton energy efficiency. The customizable roll widths (1200–3000mm) allow us to serve both retail and industrial clients without retooling downtime. Maintenance is straightforward thanks to the open-access design and clear PLC diagnostics."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Miguel Santos - Plant Supervisor, TerraFiber Co.

"Solid performance on recycled kraft pulp—exactly what we needed for our eco-line. The twin-wire forming section delivers uniform thickness, and the 12-zone dryer gives us excellent moisture control. Only reason I’m not giving five stars is the initial setup took longer than expected due to calibration of the auto-feeding system. Once optimized, though, throughput improved by 45%."Purchase Date: May 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Anika Rao - Production Head, PrimeBox Manufacturing

"We went with the Base Model to scale up without over-investing upfront. Even at 300m/min, it outperforms our old line. The semi-automated conveyor system cut labor needs by nearly half, and the PLC interface is intuitive enough that training took just two days. It’s built like a tank—no issues despite constant 24/7 operation. We’re already planning to add a second unit."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Dr. Ethan Cole - Materials Innovation Lab

"We’re using the machine not for mass production but for prototyping specialty paper composites. The full parameter tuning on the Pro Model lets us adjust thickness down to 0.1mm and test different pulp blends with precision. Real-time monitoring helps us collect production data for research. It’s rare to find industrial equipment this adaptable for experimental use."Purchase Date: April 2025 | Usage Period: 2 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rebecca Lang - Industrial Process Engineer & Paper Tech Consultant

"The 3200MM Twin Wires machine sets a new benchmark in mid-to-high-end kraft paper production. Its combination of modular design, PLC precision, and energy-efficient drying makes it ideal for manufacturers transitioning to smart, sustainable operations. The Pro Model’s 30% energy reduction aligns with ISO 14001 standards—something auditors increasingly prioritize."

Marcus Lin - Waste Reduction & Green Manufacturing Specialist

"Few paper machines handle recycled pulp as effectively as this one. The automatic parameter adjustment prevents quality drops when switching between virgin and post-consumer fiber. For companies serious about circular production, this machine offers both performance and environmental accountability—a rare balance in heavy industrial equipment."

Posted: 5 days ago

"After evaluating three different systems, this one stood out for its automation depth. The real-time monitoring caught a roller misalignment before it caused downtime. Customer support responded in under two hours. Impressive."

Posted: 12 days ago

"We started with the Base Model and just upgraded to the Advanced. The scalability is incredible. Being able to switch between tissue and cardboard-grade kraft paper without delays has helped us win new contracts."

Posted: 3 weeks ago

"Running non-stop for 180 days with only scheduled maintenance. The safety barriers and emergency stops have already prevented two potential incidents. Only suggestion: include more video tutorials for first-time PLC users."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.