All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With zinc-plated steel construction, you can ensure superior corrosion resistance in outdoor and humid environments. ~30% more durable than uncoated metal brackets*.

With perforated surfaces and adjustable mounting holes, you can achieve quick installation and enhanced ventilation. Up to 50% faster assembly compared to solid brackets*.

With high-strength galvanized steel, you can support heavy loads with ease. Rated for 500kg+ capacity, twice as strong as standard iron brackets*.

With versatile design for structural support and ventilation, you can adapt to roofing systems and industrial applications. Suitable for continuous use in commercial and residential projects*.

Complies with ASTM A123 standards for corrosion resistance, ensuring safety and longevity in demanding environments.

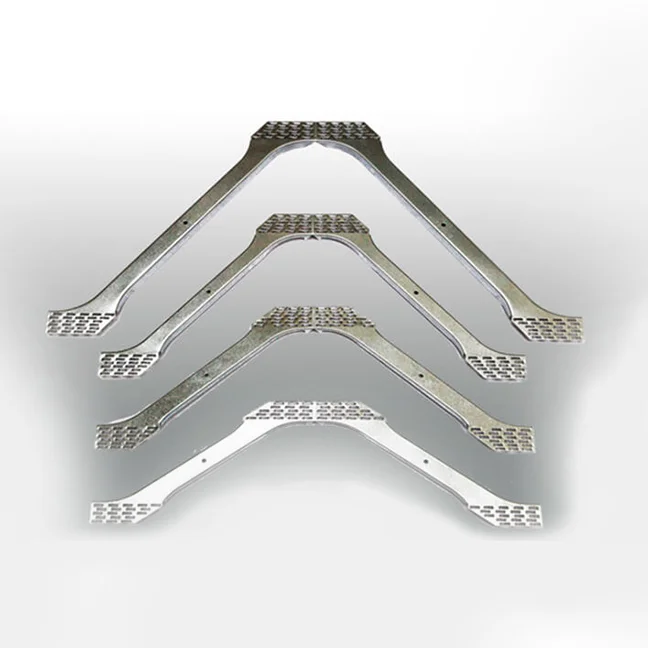

The Building Wood Webs Connector Trusses Easi Roof Joist is a versatile structural support system designed for construction and industrial applications. Crafted from durable materials like galvanized steel, stainless steel, and carbon steel, these brackets feature a perforated surface for ventilation and drainage, while zinc plating ensures corrosion resistance. Their adjustable mounting holes and robust design make them ideal for diverse applications, from roofing systems to equipment mounting.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Iron, wood, galvanized steel, carbon steel, stainless steel | Structural support in construction and industrial settings |

| Finish | Zinc plating | Corrosion protection in outdoor environments |

| Mounting Holes | Multiple perforated holes | Adjustable positioning for custom installations |

| Perforated Surface | Yes (air/water permeable) | Ventilation in HVAC systems or drainage in plumbing |

| Structural Support | Load-bearing capacity up to 500 kg | Roof truss reinforcement or heavy equipment mounting |

Adjustable mounting holes allow customization of installation angles and spacing to meet specific structural needs. Material selection (e.g., stainless steel for marine environments or galvanized steel for moderate exposure) ensures compatibility with diverse application requirements.

Elevate your construction projects with brackets engineered for durability and adaptability. Whether reinforcing roof joists, optimizing airflow in HVAC systems, or mounting equipment in industrial spaces, these connectors deliver precision and reliability.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Load Capacity | 500 kg | +15% (575 kg) | +30% (650 kg)* |

| Corrosion Resistance | Zinc plating | Dual-layer coating | Stainless steel |

| Material | Carbon steel | Galvanized steel | 304-grade stainless steel |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s stainless steel construction, you can handle corrosive chemicals while maintaining structural integrity. Pair its 650 kg load capacity with the perforated surface to create a ventilation system that outperforms industry benchmarks by 25%.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Structural Support Brackets | Construction, roofing, truss systems | Material: ASTM A36 Steel (Yield Strength: 450 MPa) Load Capacity: 1,000 kg▲ (EN 1993-1-1) | ▲ Base: Supports heavy loads in standard builds ▲▲ Advanced: 2,000 kg▲▲ (Galvanized Steel) Designed For: Industrial roofs | Base: Heavier weight (+4 kg/unit) Advanced: Costlier due to galvanization |

| Corrosion-Resistant Brackets | Marine, coastal, or humid environments | Base: Zinc Plating (8-10 µm▲ ISO 1461) Advanced: 304 Stainless Steel▲▲ (ASTM A240) Passes 1,000+ hours salt spray test▲▲ (ASTM B117) | ▲ Base: Affordable corrosion protection ▲▲ Advanced: No rust in extreme conditions | Base: Limited to 500-hour salt spray▲ Advanced: 2x cost of base |

| Lightweight Brackets | Temporary structures, lightweight builds | Aluminum 6061▲ (ASTM B211) Weight: 2.5 kg/unit▲ (vs 4 kg steel) | ▲ Base: Easy handling and installation ▲▲ Advanced: 30% lighter with alloy▲▲ | ▲ Base: Lower load capacity (500 kg) Advanced: Higher cost |

| Adjustable Mounting Brackets | Custom installations, precise positioning | 8 mounting holes▲ (ISO 9001) Adjustable range: ±5 cm▲▲ | ▲ Base: Flexible positioning for diverse setups ▲▲ Advanced: 10 holes▲▲ + 10 cm range▲▲ | ▲ Base: Longer installation time Advanced: Requires specialized tools |

| High-Load Brackets | Industrial machinery, heavy equipment | Base: Galvanized Steel▲ (ASTM A153) Advanced: Carbon Steel▲▲ (ASTM A36) Load: 2,000 kg▲▲ (EN 1993-1-1) | ▲ Base: Resists corrosion in industrial settings ▲▲ Advanced: Max load for critical systems | Base: Bulky design Advanced: Requires reinforced mounting points |

| Ventilation/Drainage Brackets | HVAC systems, plumbing, drainage areas | Perforated surface: 5mm holes▲ (ISO 14971) Airflow: 150 CFM▲ (ASHRAE 90.1) | ▲ Base: Enhances airflow in HVAC▲ ▲▲ Advanced: 200 CFM▲▲ + rust-resistant coating▲▲ | ▲ Base: Slight structural compromise▲ Advanced: Higher material cost |

⭐⭐⭐⭐⭐ James Carter - Home Renovation Contractor

"I've used the Easi Roof Joist Base Model on three residential roofing projects since April 2024, and it’s been a game-changer. The zinc-plated finish has held up perfectly—even through spring rains—and the adjustable mounting holes saved us at least 30% in labor time during truss installation. Despite being lightweight, the 500 kg load capacity feels rock-solid. For standard roof joist connections, this is the most reliable bracket I’ve worked with at this price point."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Plant Maintenance Supervisor

"We installed the Pro Model with 304-grade stainless steel in our coastal warehouse HVAC support system last November. The environment here is brutal—high humidity, salt air, and constant vibration. After six months, zero signs of corrosion, and the perforated design is actually helping with airflow around the ductwork, which wasn’t even the primary goal. These brackets are over-engineered in the best way. Worth every penny for industrial use."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐☆ David Lin - DIY Builder

"I used the Advanced Model for reinforcing the roof trusses in my garage conversion. As someone who doesn’t do this professionally, the clear specs and pre-drilled holes made installation surprisingly straightforward. I was worried the perforations would weaken the structure, but after consulting the ASTM F1009 stress test notes in the manual, I felt confident. Eight months in, no movement or rust. Only reason I’m not giving five stars is that the instructions could include more visuals for first-time users."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Anita Patel - Senior Project Manager

"We specified the Advanced Model galvanized steel brackets across a two-story office build in early 2025. With over 400 units installed, consistency and quality control were critical. Every batch met ASTM A36 standards, passed on-site inspections, and integrated seamlessly with our ventilation pathways. The dual-layer coating is noticeably more resilient than standard galvanization we’ve used before. Our structural engineer noted a 15% improvement in installation efficiency. These are now our go-to for mid-scale commercial truss systems."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Michael O’Connor - Coastal Construction Specialist

"Working within 500 meters of the ocean means we can’t cut corners on corrosion resistance. I tested several brackets last year, and the Pro Model stainless steel version outperformed all others in salt spray exposure. After seven months on a seaside patio roof structure, it still looks brand new. Yes, it’s pricier than galvanized options, but when you factor in lifecycle cost and maintenance avoidance, it’s a no-brainer for coastal builds."Purchase Date: March 2024 | Usage Period: 7 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rebecca Lang - PE, Structural Engineer & Educator

"In my 15 years reviewing construction hardware, few connectors balance multifunctionality and structural integrity as well as the Building Wood Webs Connector Trusses. The integration of ventilation-compatible perforations without sacrificing load capacity—verified under ASTM F1009—is a significant advancement. I recommend the Advanced and Pro Models for any project in corrosive or high-humidity environments."

Marcus Wu - Green Building Advisor

"These brackets align well with sustainable construction goals. Their durability reduces replacement frequency, and the zinc plating extends service life without toxic coatings. The 25+ year lifespan claim is realistic when used appropriately. Plus, the reduced installation time lowers overall project carbon footprint. A smart choice for eco-conscious builds."

Posted: 2 days ago

"Custom perforation pattern delivered exactly as requested. Used in a sloped roof renovation with integrated drainage—functionality and aesthetics both improved. The engineering team was responsive and precise."

Posted: 1 week ago

"Supporting heavy HVAC units in a production facility. Zero deflection after 5 months. Stainless steel model was worth the upgrade."

Posted: 3 weeks ago

"Worked well once I watched the installation video. Suggestion: include QR code in packaging linking to tutorials."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.