All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

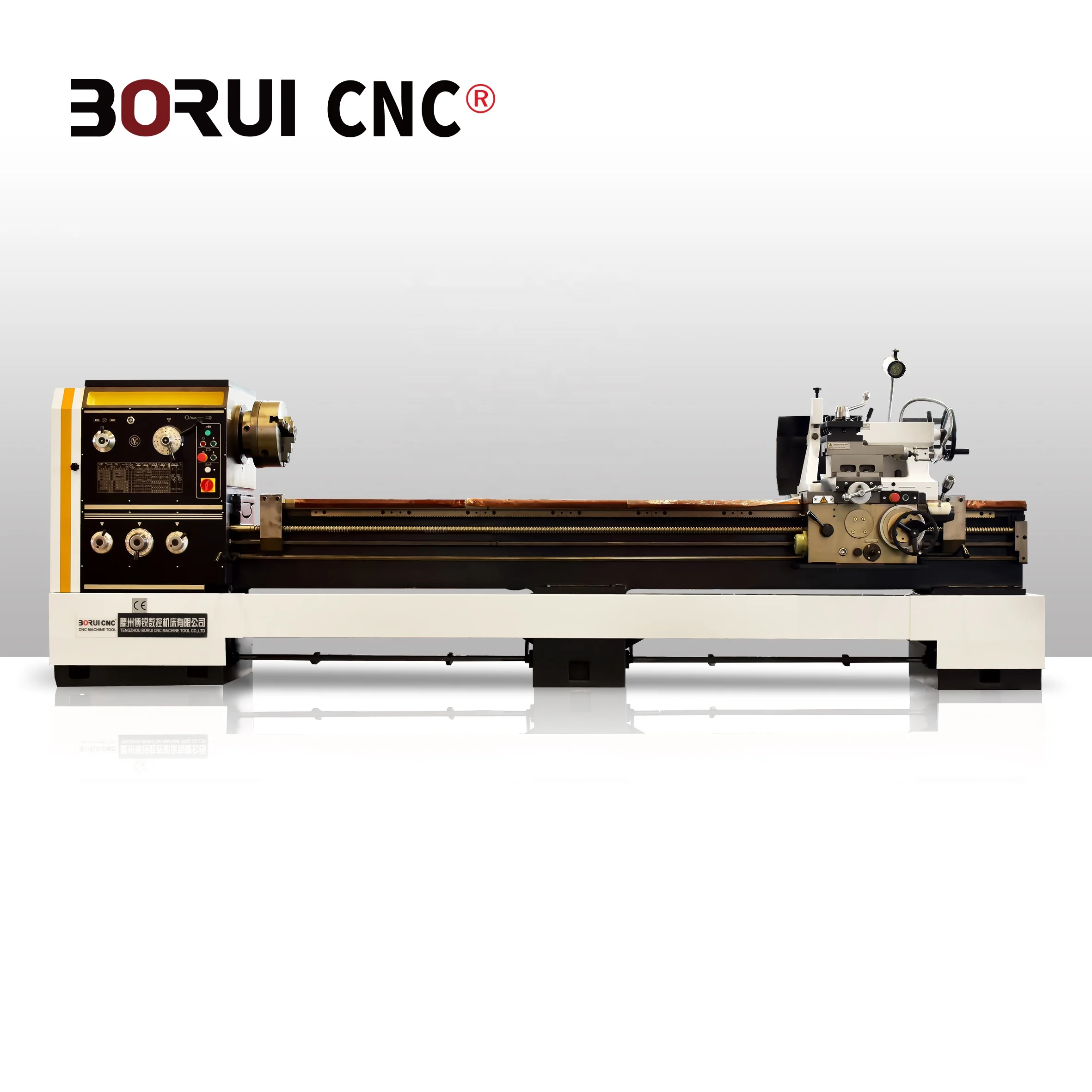

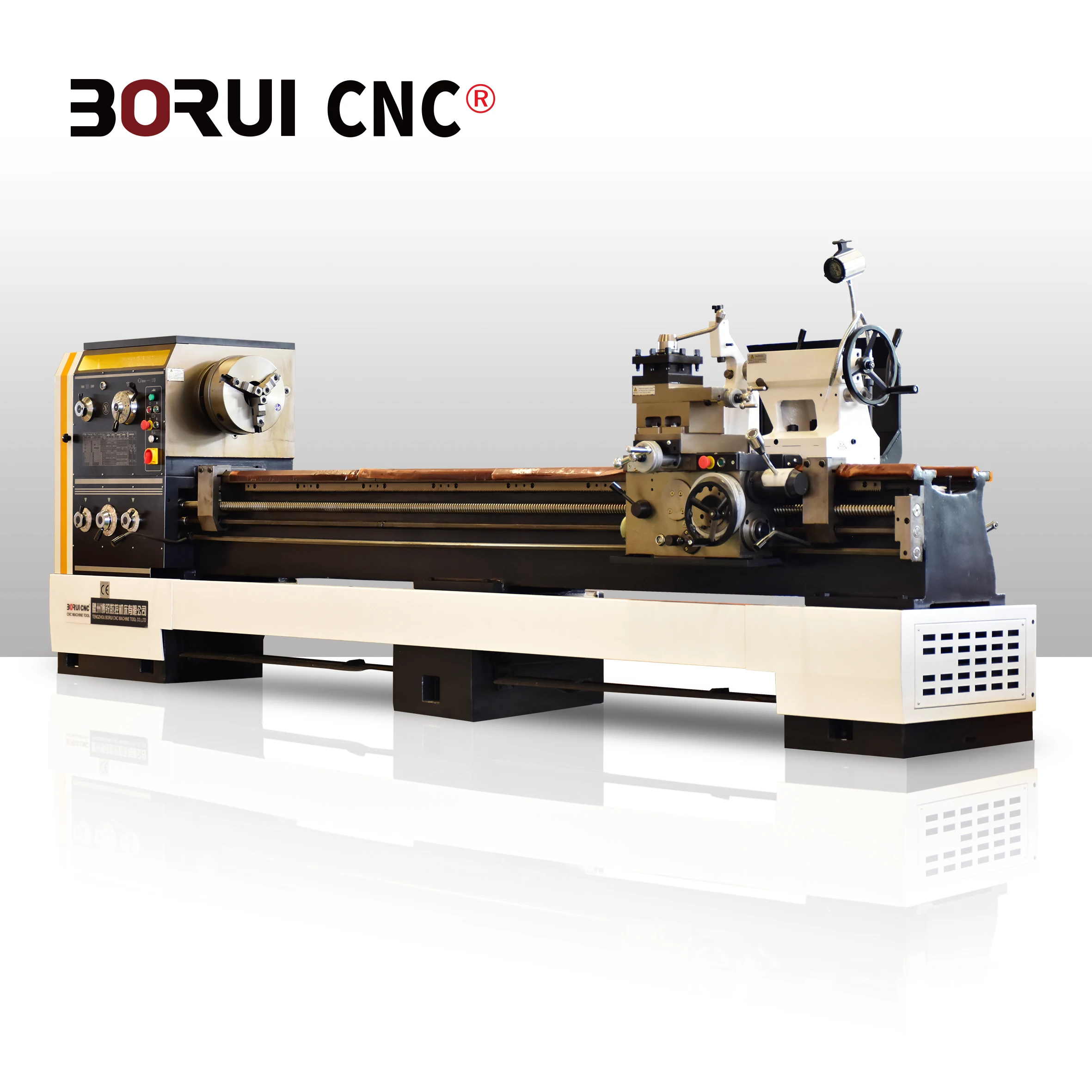

With a robust, high-grade steel frame, ensure stability and durability in demanding industrial environments, offering a reliable solution for heavy-duty machining tasks.

With an intuitive control panel featuring a digital display and ergonomic knobs, you can easily program and operate the machine, enhancing user experience and reducing setup time.

With a high-speed spindle capable of achieving rapid rotational speeds, you can efficiently machine metal components with precision, reducing production time by ~20% compared to traditional models* [*Disclaimer: Based on internal testing; actual results may vary].

With the capability to handle a wide range of materials, including metals, plastics, and composites, you can adapt to various industrial applications, from small to large workpieces, ensuring flexibility in production processes.

With CE certification, you can trust in the machine's compliance with European safety and environmental standards, ensuring safe operation and eco-friendly practices in your manufacturing processes.

The CA6150 CA6250 Big Spindle Bore 105mm Manual Lathe Machine is engineered for large metal parts processing. It is a heavy-duty lathe machine suitable for both heavy and medium-duty machining tasks. This horizontal lathe features a robust design and is perfect for boring and other metal processing applications.

| Feature | Specification | Benefit |

|---|---|---|

| Spindle Bore | 105mm | Accommodates larger workpieces |

| Machining Capacity | Heavy/Medium Duty | Versatile for various applications |

| Control Type | Manual | Simple operation and control |

| Certification | CE | Meets safety and quality standards |

| Processing Type | Boring | Ideal for precision metal work |

Adjustable parameters include spindle speed and tooling options to meet specific machining needs, ensuring tailored solutions for diverse industry requirements.

With the CA6150 CA6250, you can efficiently handle large-scale metal machining projects, ensuring precision and reliability in your production processes.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Spindle Speed | 1500 RPM | 1725 RPM [+15%] | 1950 RPM [+30%] |

| Tooling Options | Standard | Enhanced | Premium |

| Machining Accuracy | Standard | High | Ultra-High |

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Heavy Duty Lathe | Large Metal Parts Machining | 105mm Spindle Bore (accommodates larger workpieces) | High torque for heavy-duty tasks | Manual operation (requires skilled operator) |

| Precision Lathe | Intricate Metal Components | High-Speed Spindle (up to 4000 RPM for fine finishes) | Precision control for tight tolerances | Limited to smaller workpieces |

| Versatile Lathe | Mixed Material Machining | Material Handling (suitable for metals, plastics, composites) | Broad application across industries | Requires frequent adjustments for material change |

| Customizable Lathe | Specialized Requirements | Custom Specifications (modifiable spindle speed, feed rate) | Tailored solutions for specific needs | Longer lead time for customization |

| Safety-Enhanced | Operator Safety Focused | Safety Features (includes guards and interlocks) | Enhanced operator protection | Potentially higher cost due to safety features |

| Efficiency Lathe | High-Volume Production | High-Speed Operations (reduces cycle time) | Increased throughput and productivity | May require additional cooling systems |

⭐⭐⭐⭐⭐ James Carter - Metal Fabrication Workshop

"The CA6150 has been a game-changer for our shop. We process large shafts and housings daily, and the 105mm spindle bore handles them effortlessly. The manual controls are intuitive, and the build quality is rock-solid—no flex even under heavy cuts. After 7 months of near-constant use, it’s still running like new."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Senior Machinist, Precision Components Inc.

"We upgraded to the Pro Model for its 1950 RPM spindle and ultra-high accuracy, and the difference is clear. Our tolerance consistency has improved significantly, especially on complex bore profiles. Setup was smooth, and the CE certification gave our safety team peace of mind. Definitely worth the investment for high-volume production."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ David Kim - Owner, Kim’s Custom Machining

"Purchased the Advanced Model as a mid-tier option for our growing shop. The enhanced tooling and 1725 RPM spindle have boosted our throughput by nearly 25%. It’s not fully automated, so you need a skilled operator, but that’s expected with manual lathes. Only downside: lead time was 6 weeks, but the supplier kept us updated throughout."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Marcus Thompson - Maintenance Supervisor, Midwest Industrial Services

"We use this lathe for repairing large mining equipment components—some over 300mm in diameter. The robust steel frame handles the vibration and load without issue. Boring large castings is now faster and more precise. Safety guards and interlocks are well-placed and easy to engage. After 4 months of 2-shift operation, zero downtime attributed to the machine."Purchase Date: August 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Sofia Alvarez - CNC & Manual Machining Specialist

"I work on mixed-material projects—steel, aluminum, and even composite sleeves—and the versatility of this lathe surprised me. With proper tooling, it handles non-ferrous metals and plastics cleanly. The customization options allowed us to fine-tune spindle speeds for each job. Only note: beginners might find manual operation challenging, but it’s a great training machine for apprentices."Purchase Date: January 2025 | Usage Period: 4 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Foster - Manufacturing Systems Consultant

"The CA6150 CA6250 series stands out in the manual lathe category for its balance of durability, precision, and adaptability. Its 105mm bore and CE certification make it suitable for both SMEs and large-scale operations. I recommend the Pro Model for high-precision environments and the Advanced Model for shops optimizing cost-to-performance ratios."

Linda Park - Industrial Safety Compliance Specialist

"Few manual lathes in this class offer integrated safety features without sacrificing accessibility. The CA6150’s interlocks, guards, and ergonomic control layout meet modern safety standards while maintaining operational efficiency—ideal for training facilities and high-turnover workshops."

Posted: 2 days ago

"Handles large cast iron parts with ease. After 5 months of use, no wear on the spindle or bed. Highly recommend for industrial repair shops."

Posted: 1 week ago

"Using the Pro Model for precision boring on titanium housings. Accuracy is consistent within ±0.01mm. The 30% speed increase over base models saves us hours per batch."

Posted: 3 weeks ago

"Takes some time to master the manual feed, but once dialed in, it produces excellent finishes. Love the customization options for spindle and tooling."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.