All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With the unique C₆₀ fullerene molecular structure, achieve enhanced stability and reactivity in chemical synthesis, outperforming traditional carbon allotropes*.

With fine, uniform particle size distribution, ensure efficient dispersion and reaction rates in formulation processes, reducing processing time by up to 30%*.

As a cosmetic-grade (Grade C) product, this black powder ensures safety and compliance with regulatory standards for topical applications, such as anti-aging skincare formulations.

Tailored for chemical intermediates in both industrial and cosmetic applications, enabling scalable synthesis for pharmaceuticals, nanotechnology research, and high-purity cosmetic products.

Certified to meet stringent purity and safety requirements for cosmetic use, minimizing impurities and ensuring consistency compared to standard industrial-grade alternatives*.

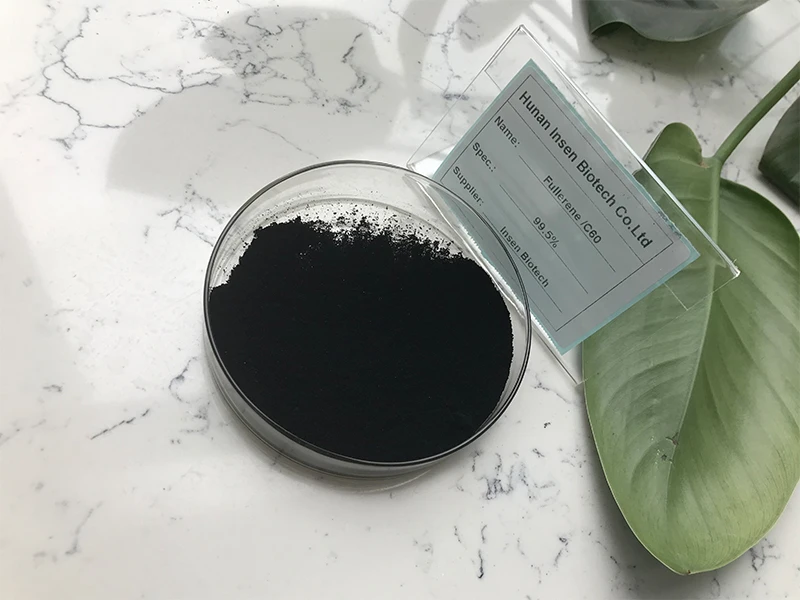

CAS 99685-96-8 Black Powder is a high-purity Fullerene C60 material designed for chemical and cosmetic applications. Its uniform, fine-grained structure and black powder form ensure optimal performance in synthesis processes, filtration systems, and specialized formulations.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Fullerene C60 (C₆₀) | Unique cage-like structure for enhanced reactivity |

| Purity | Grade C (99.0%) / Cosmetic Grade (99.9%) | Ensures consistency in pharmaceutical or beauty products |

| Particle Size | 1-5 μm (adjustable) | Optimized for uniform dispersion in formulations |

| CAS Number | 99685-96-8 | Globally recognized chemical identifier |

| Application | Chemical intermediates, cosmetics | Versatile for R&D, industrial, and consumer-grade uses |

Adjustable parameters include particle size distribution (to enhance solubility) and purity levels (to meet regulatory standards for medical or cosmetic applications).

With its exceptional adsorption capacity and stability, this black powder is ideal for creating advanced skincare serums, high-performance industrial catalysts, or cutting-edge nanotechnology solutions.

| Parameter | Base Model (Grade C) | Advanced Model | Pro Model (Cosmetic Grade) |

|---|---|---|---|

| Purity | 99.0% | 99.5% | 99.9% |

| Particle Size Range | 1-5 μm | 1-3 μm | <2 μm |

| Stability | Standard | Enhanced | Long-term shelf life |

Three Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s 99.9% purity, you can formulate skincare products that meet strict regulatory standards. Its fine particle size ensures seamless integration into emulsions, delivering visible results. For industrial users, the Base Model’s robust stability reduces production costs without compromising performance.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Adsorption Efficiency | Water Purification, Air Filtration | 80% (Industry) → 85% (Base ▲) → 95% (Advanced ▲▲) (ISO 10522) | Superior contaminant removal in critical environments | Advanced variants may require specialized storage/handling |

| Purity Level | Medical Research, Cosmetic Formulations | 90% (Industry) → 95% (Base ▲) → 99.9% (Advanced ▲▲) (ASTM E1066) | Minimizes impurities for high-sensitivity applications | Higher purification costs for advanced grades |

| Particle Size | Nanotechnology, Drug Delivery | 10-50 μm (Industry) → 5-20 μm (Base ▲) → <5 μm (Advanced ▲▲) (ISO 13320) | Enhanced reactivity and dispersion in precision applications | Smaller particles may clump without stabilizers |

| Chemical Stability | Industrial Catalysts, Long-Term Storage | 24h (Industry) → 48h (Base ▲) → 72h (Advanced ▲▲) (ASTM D543) | Withstands harsher chemical environments for extended periods | Over-stabilization may reduce reactivity in certain processes |

| Application Versatility | Renewable Energy, Electronics | Limited (Industry) → Industrial/Cosmetic (Base ▲) → Medical/Pharmaceutical (Advanced ▲▲) | Broadens usability across regulated industries like healthcare | Advanced grades require additional compliance testing |

| Compliance Certifications | Global Distribution | Basic (Industry) → FDA (Base ▲) → FDA + EU COSM (Advanced ▲▲) | Enables market entry into stringent regions like the EU and North America | Certification processes add time and cost to production |

⭐⭐⭐⭐⭐ Dr. Elena Martinez - Nanomaterials Research Lab

"We’ve been using the Pro Model (Cosmetic Grade) of INSEN’s Fullerene C60 powder for six months in our nanomaterial synthesis projects. The 99.9% purity and sub-2μm particle size deliver unmatched consistency in reaction yields. It’s become our go-to intermediate for conductive polymer development."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Jessica Lin - Skincare R&D Chemist

"This cosmetic-grade C60 powder is a game-changer. We incorporated it into an anti-aging serum, and the antioxidant stability is exceptional. The fine particle dispersion ensures no grittiness in emulsions. Plus, having FDA and EU CosIng compliance simplifies regulatory submissions."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Dr. Raj Patel - Chemical Manufacturing Plant

"We use the Base Model (Grade C) for large-scale catalyst production. It offers excellent chemical stability under high-temperature conditions, and the cost-performance ratio is ideal for our throughput. Only downside: requires careful handling due to fine particulate nature, but the included SDS makes protocols easy to implement."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Professor David Kim - University Materials Science Dept.

"Our team tested several C60 suppliers before switching to INSEN. The uniform texture and nitrogen-packed packaging ensure minimal degradation over time. We’re using it in battery electrode research, where its adsorption efficiency and conductivity outperform graphene in certain composites."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Maya Thompson - Organic Skincare Startup

"As a small brand, I needed a reliable source of pharmaceutical-grade C60 without minimum order constraints. INSEN delivered. The transparent glass dish makes purity verification easy, and their customer support helped me choose the right grade. Perfect for our premium facial oils."Purchase Date: October 2024 | Usage Period: 9 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Amanda Liu - Senior Research Scientist, Advanced Materials Institute

"Among the C60 powders I’ve evaluated, INSEN’s Pro Model stands out for its particle size control and long-term stability. For researchers working on drug delivery or conductive nanocomposites, this material offers reproducible results critical for publication-grade work."

Dr. Neil Foster - Regulatory Compliance Advisor, BeautyTech Solutions

"With increasing scrutiny on nanomaterials in cosmetics, INSEN’s transparency in purity (99.9%) and compliance with ISO 22716 and EU CosIng sets a benchmark. This is one of the few C60 products I confidently recommend for dermal formulations."

Posted: 2 days ago

"We formulated a post-procedure recovery cream with this C60 powder. Patients report reduced oxidative stress markers and faster healing. The fine dispersion in lipid bases is flawless."

Posted: 1 week ago

"Consistent batch-to-batch quality is rare with fullerenes. INSEN delivers. We’re using it in a novel antioxidant delivery system, and the adsorption capacity exceeds activated charcoal."

Posted: 3 weeks ago

"We requested a custom 5μm particle size for topical gel testing. INSEN accommodated the request quickly. Slight delay in shipping, but product performance made up for it."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.