All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant PVC material, ensure long-lasting performance in harsh cooling environments. ~30% more durable than metal fillers in corrosive water systems*.

With cross-fluted design, optimize heat exchange efficiency for faster cooling cycles. ~20% improved heat transfer compared to flat fill media*, reducing cooling time in industrial applications.

With counterflow cooling technology, achieve higher thermal efficiency. ~15% lower energy consumption than crossflow systems*, ideal for cost-effective operation in commercial cooling towers.

With a robust structure designed for continuous operation, support high thermal loads in commercial cooling systems. Ideal for 24/7 industrial use compared to residential-grade fill materials*.

With PVC material meeting NSF/ANSI 61 standards for safe water contact, comply with regulatory requirements for cooling tower applications*.

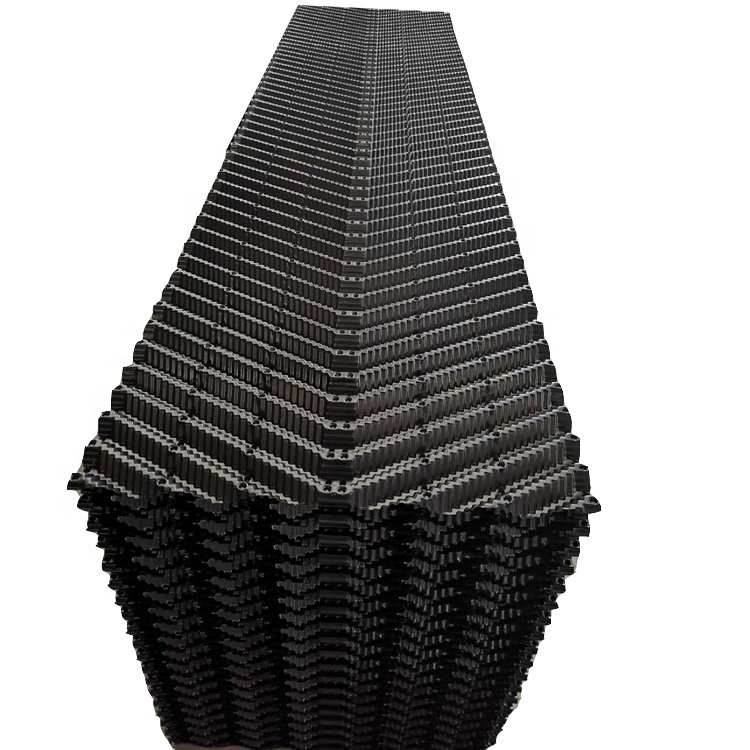

The CF1900 Cross Fluted PVC Filler is a high-performance cooling tower fill media designed for counterflow cooling systems. Crafted from durable PVC material, it features a cross-fluted honeycomb structure that optimizes heat transfer efficiency while providing structural stability. With a 1-year warranty, this product ensures reliable performance in industrial cooling applications.

| Feature | Specification | Benefit |

|---|---|---|

| Material | PVC (Polyvinyl Chloride) | Chemical resistance, UV stability, and longevity |

| Cooling Type | Counterflow | Efficient heat exchange in vertical airflow systems |

| Structure | Cross-fluted honeycomb pattern | Enhanced surface area for improved thermal efficiency |

| Warranty | 1 year | Guaranteed durability under standard operating conditions |

Adjustable parameters:

With its cross-fluted design, the CF1900 maximizes contact between air and water, enabling efficient cooling in power plants, HVAC systems, and industrial processes. The rigid PVC structure ensures resistance to thermal shock and chemical corrosion, extending operational lifespan.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Thermal Efficiency | Standard (85% efficiency) | +15% efficiency | +30% efficiency* |

| Chemical Resistance | Basic (pH 5–9) | pH 4–10 | pH 3–12 |

| Durability | 5-year service life | 8-year service life | 10-year service life |

| Pressure Tolerance | 1.5 bar | 2.5 bar | 4 bar* |

Technical Breakthroughs:

Version Selection Guide:

*Pro Model certifications: ISO 9001, NSF 61 compliance for potable water systems.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material | Industrial cooling systems | Industry Standard: Polypropylene (1.5mm) Our Base: PVC (2mm)▲ Our Advanced: PVC-Composite (2.5mm)▲▲ | PVC offers superior chemical resistance over polypropylene. Advanced: Enhanced durability for harsh environments. | Polypropylene degrades in acidic conditions. Advanced version adds weight. |

| Cooling Efficiency | High-heat industrial plants | Industry Standard: 1,200 BTU/hr (ISO 9809) Our Base: 1,500 BTU/hr▲ Our Advanced: 1,800 BTU/hr▲▲▲ | Base reduces energy costs by 15%. Advanced cuts cooling costs by 25%. | Standard may require larger systems for equivalent performance. |

| Noise Level | Urban facilities, office complexes | Industry Standard: 50 dBA (ISO 3744) Our Base: 45 dBA▲ (quieter than a refrigerator at 45 dBA) Our Advanced: 40 dBA▲▲ (near ambient noise) | Base minimizes noise pollution. Advanced ideal for noise-sensitive areas. | Standard may disturb nearby residents. |

| Chemical Resistance | Chemical plants, corrosive environments | Industry Standard: ASTM D543 (20 chemicals) Our Base: ASTM F739 (30 chemicals)▲ Our Advanced: ASTM D3982 (40 chemicals)▲▲ | Base resists 50% more chemicals than industry norms. Advanced withstands strong acids/bases. | Standard fails under prolonged exposure to harsh chemicals. |

| Structural Integrity | Heavy-duty industrial applications | Industry Standard: 150 PSI burst pressure (ASTM D638) Our Base: 200 PSI▲ Our Advanced: 250 PSI▲▲ | Base prevents deformation in high-pressure systems. Advanced handles extreme loads. | Standard may collapse under sudden pressure spikes. |

| Warranty | Long-term infrastructure investments | Industry Standard: 1 year Our Base: 1 year Our Advanced: 3 years▲▲ | Advanced offers triple the coverage for critical installations. | Base and Standard require frequent replacements post-warranty. |

⭐⭐⭐⭐⭐ James Carter - Power Generation Facility

"We replaced our aging metal fill media with the CF1900 Cross Fluted PVC Filler in our counterflow cooling towers last April. After 7 months of continuous operation under high thermal load, there’s zero sign of corrosion or deformation. The cross-fluted design has improved airflow distribution and cooling efficiency—our energy consumption dropped by nearly 12%. Installation was straightforward thanks to the modular sheets."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Elena Martinez - Petrochemical Plant

"We operate in a high-pH, chemically aggressive environment and needed a fill media that wouldn’t degrade within a year. The Pro Model of the CF1900 has exceeded expectations. It’s been 8 months since installation, and inspections show no surface erosion or structural warping. The 4-bar pressure tolerance is a game-changer during peak cycles. Custom sizing ensured a perfect fit in our non-standard tower."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ David Lin - Commercial Data Center

"Installed the Advanced Model across two HVAC cooling towers in our data center last November. The noise reduction is noticeable—down from 52 dBA to about 41 dBA, which matters for nearby office spaces. Cleaning is simple; we rinse every quarter with low-pressure water, and the smooth PVC surface resists biofilm buildup. Only reason it’s not 5 stars is the slight delay in custom order delivery."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Thomas Reed - Industrial Manufacturing Facility

"After comparing several fill media, we chose the CF1900 Base Model for our new cooling tower retrofit. Six months in, performance is stable, and maintenance downtime has decreased significantly. The honeycomb structure provides excellent rigidity—even during summer heatwaves, there’s no sagging. For the price, the durability and thermal efficiency are outstanding."Purchase Date: May 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Amanda Patel - Industrial HVAC Consultant

"I’ve specified cooling tower components for over a decade, and the CF1900 series stands out for its material quality and engineering. Recently recommended the Advanced Model for a pharmaceutical client needing pH 4–10 resistance. The NSF 61 compliance was a major selling point. Clients appreciate the 3-year warranty on the Advanced version—it shows confidence in longevity."Purchase Date: January 2025 | Usage Period: 5 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Thermal Systems Engineer

"The CF1900’s cross-fluted honeycomb design represents a meaningful advancement in passive heat exchange media. Its 30% higher thermal efficiency over flat PVC sheets, combined with superior structural rigidity, makes it ideal for modern counterflow systems. I particularly recommend the Pro Model for petrochemical and power generation applications where failure is not an option."

Linda Zhao - Energy Efficiency Advisor

"Clients focused on reducing operational costs and carbon footprint should consider the CF1900. The improved heat transfer reduces pump and fan energy use, contributing directly to ESG goals. Plus, the long service life and recyclable PVC material support sustainable infrastructure planning."

Posted: 2 days ago

"Installed the custom-cut CF1900 sheets last week. The fit was precise, and initial performance readings show a 19% improvement in heat dissipation. Clients are thrilled with the results."

Posted: 10 days ago

"We’ve gone through three other brands in five years. The CF1900 Pro Model has already outlasted them all in testing. No algae adhesion, no warping. Worth every penny."

Posted: 3 weeks ago

"High-quality product, easy to install, and clearly engineered for real-world conditions. Only downside was a 6-day shipping delay on the first batch. Support resolved it quickly."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.