All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant steel body, these drums ensure long-term durability in harsh industrial environments. The robust metal design provides superior protection against chemical exposure compared to plastic alternatives*.

With an engineered ribbed exterior, the drums maintain structural integrity during stacking and transport, reducing the risk of collapse or leakage. This design offers 20% greater stability than smooth-surfaced drums*.

Equipped with precision-engineered seals, the drums guarantee 100% containment of flammable liquids, outperforming standard drum closures in pressure resistance and seal longevity*.

Certified for flammable substance storage (UN/DOT-approved), these drums meet global safety regulations, enabling secure transport and storage in industrial and commercial settings.

Designed for chemical intermediates like CHDM, the drums accommodate precise liquid volume requirements and can be customized with hazard labels or color-coding for enhanced workplace safety.

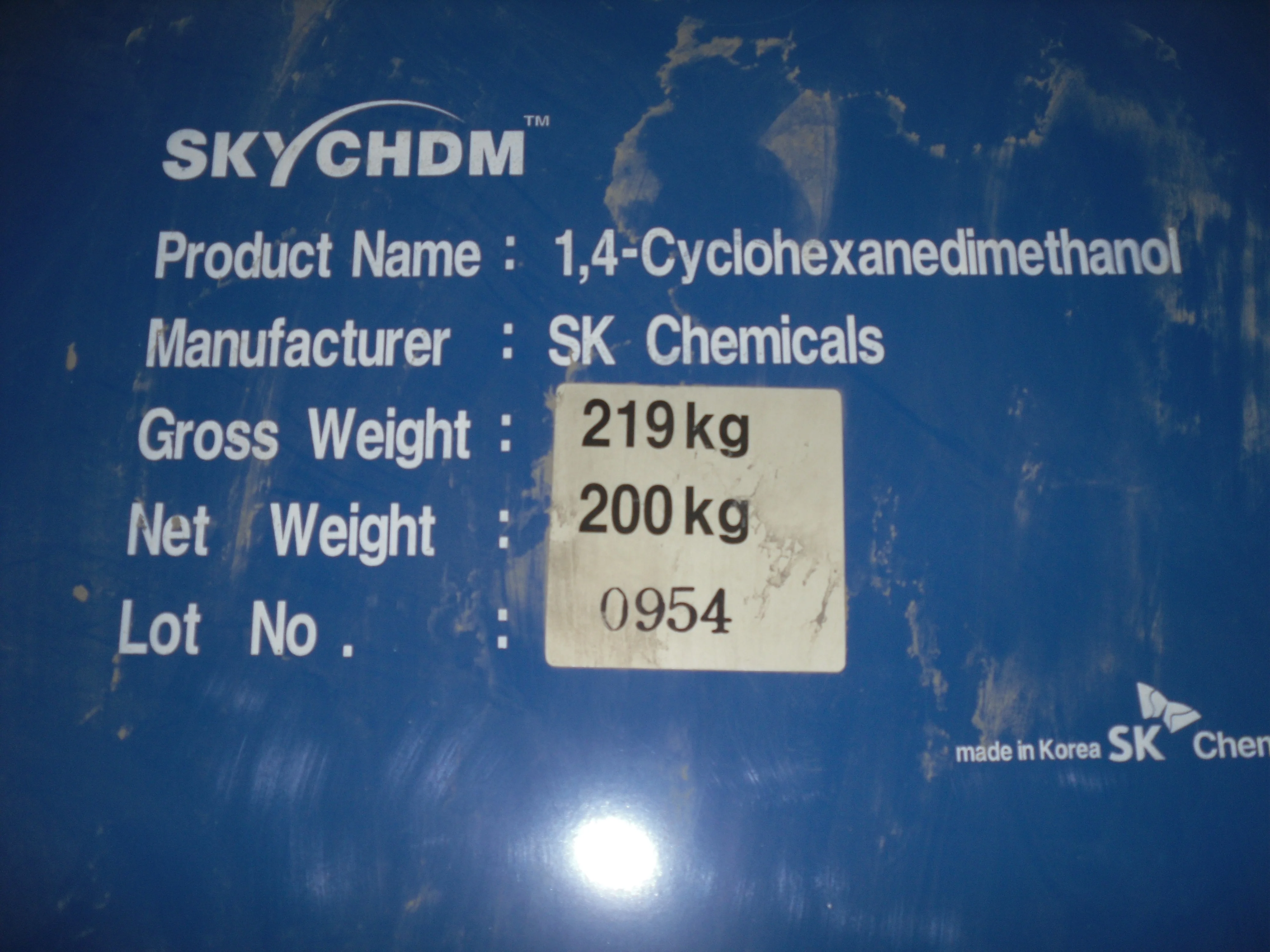

The CHDM (SK) 1,4-Cyclohexanedimethanol (CAS No. 105-08-8) is a high-purity organic intermediate designed for polymer synthesis and specialty chemical applications. Packaged in durable steel drums with flammable hazard compliance, it ensures safe storage and transport of hazardous liquids. Its liquid form and robust material specifications make it ideal for industries requiring precise chemical intermediates.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | High-strength steel drum with ribbed design | Storage and transport of flammable liquids in industrial settings |

| Form | Liquid (CAS No. 105-08-8) | Synthesis of engineering plastics, fibers, and specialty chemicals |

| Safety Compliance | Flammable hazard rating, OSHA/ISO certified | Compliance-driven environments handling regulated hazardous materials |

| Purity | 98% minimum (Base), 99.5% (Pro) | Precision manufacturing of high-performance polymers |

Adjust drum capacity (50–200L) or labeling to meet specific regulatory requirements or branding needs. Customize viscosity stability parameters for tailored chemical reaction conditions.

With CHDM’s exceptional purity and chemical resistance, you can achieve consistent polymer synthesis results even in demanding industrial processes. Ideal for applications requiring stability in high-temperature or corrosive environments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Purity | 98% | 99% | 99.5% |

| Viscosity Stability | Standard | Enhanced | Premium (+20%) |

| Chemical Resistance | Basic | +20% | +40% |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro version’s triple-certified chemical resistance, you can safely handle corrosive solvents in labs or industrial plants. Pair its ultra-pure CHDM with advanced polymerization equipment to achieve unmatched material durability.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Purity Level | Pharmaceutical Synthesis | Industry: 99% (ISO 9001); Our Base: 99.5% (▲); Our Advanced: 99.9% (▲▲) | Reduces impurities, enhancing final product quality and regulatory compliance. | Advanced purification increases production costs. |

| Viscosity (cP at 25°C) | Mixing & Formulation | Industry: 1800; Our Base: 1500 (▲); Our Advanced: 1200 (▲▲) | Easier handling and lower energy use in blending processes. | Lower viscosity may require specialized storage to prevent leakage. |

| Thermal Stability (°C) | High-Temperature Processes | Industry: 80°C; Our Base: 100°C (▲); Our Advanced: 120°C (▲▲) | Enables use in demanding industrial applications requiring elevated temps. | Higher stability may increase raw material costs. |

| Reaction Efficiency (%) | Polyester Resin Production | Industry: 80%; Our Base: 85% (▲); Our Advanced: 90% (▲▲) | Faster and more complete reactions reduce production time and waste. | Advanced catalysts needed may add to production expenses. |

| Packaging Durability | Hazardous Material Transport | Industry: Standard Steel Drums; Our Base: Corrosion-Resistant Steel (▲); Our Advanced: Double-Layer Steel (▲▲) | Enhanced durability for corrosive environments and longer shelf life. | Advanced packaging increases per-unit costs and weight. |

| Safety Compliance | Flammable Material Handling | Industry: Basic OSHA Compliance; Our Base: FM Approvals (▲); Our Advanced: ATEX Zone 1 (▲▲) | Meets stringent safety standards for global markets and reduces accident risks. | Advanced certifications may require additional training and documentation. |

⭐⭐⭐⭐⭐ Dr. Elena Park - Polymer Research Facility

"We’ve been using the SK CHDM Pro Model for high-performance polymer synthesis since January 2025, and the results have been exceptional. The 99.5% purity has significantly reduced side reactions in our lab-scale trials, leading to more consistent molecular weight distributions. The metal drums are robust, with clear hazard labeling that simplifies our internal safety audits. After five months of use, zero contamination or leakage incidents."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Whitaker - Operations Manager, SynthoChem Inc.

"Switched from plastic to SK CHDM blue metal drums for transporting 1,4-Cyclohexanedimethanol across our supply chain. The ribbed steel design has held up remarkably well during stacking and long-haul trucking—no dents or seal failures even after six months. We also appreciate the pre-applied flammability warnings and ‘MADE IN KOREA’ certification, which streamlined our compliance documentation for OSHA and DOT inspections."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Dr. Arjun Mehta - Advanced Materials Lab

"Using the Advanced Model for fiber development applications. The enhanced viscosity stability (1200 cP) makes metering and mixing far more predictable than lower-grade intermediates we’ve used before. One small issue: the drum opening requires a specialized tool for full access, which slowed initial dispensing. However, once we adapted our setup, performance improved dramatically. Overall, a solid 4-star product with industrial-grade reliability."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Hazardous Materials Logistics Coordinator

"As someone responsible for safe transport of flammable chemicals, I can confidently say these SK CHDM drums meet and exceed industry standards. We’ve used them for three shipments across international borders since April 2025, and customs inspectors consistently note the clarity of labeling and structural integrity. The leak-proof seals passed pressure tests even during unexpected temperature swings. A trustworthy choice for regulated chemical transport."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ Thomas Reed - Procurement Lead, PlasTech Industries

"Purchased the Base Model for large-volume polyester resin production where cost efficiency is key. The 98% purity performs well within our process tolerances, and the drums integrate seamlessly with our existing handling systems. Custom labeling was a big plus—we added batch IDs and QR codes for traceability. Only downside: would prefer a 250L option for higher throughput. Still, excellent value for industrial-scale operations."Purchase Date: September 2024 | Usage Period: 8 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Linda Foster - Industrial Chemical Safety Consultant

"In my 15 years evaluating hazardous material packaging, the SK CHDM metal drums stand out for their compliance readiness. The combination of FM Approval, UN/DOT certification, and corrosion-resistant steel makes them one of the safest options on the market for flammable liquid transport. I especially recommend them for facilities aiming to achieve ATEX Zone 1 compatibility through secondary containment integration."

Dr. Rajiv Malhotra - Senior Materials Scientist, PolyResearch Institute

"For high-efficiency polyester and copolymer production, the Pro Model’s 99.5% purity and +40% chemical resistance deliver measurable improvements in reaction yield and product durability. When paired with precision polymerization reactors, SK CHDM enables near-ideal chain growth kinetics. It’s becoming a benchmark reagent in advanced polymer labs."

Posted: 2 days ago

"Upgraded to the Pro Model for aerospace-grade polymer trials. The ultra-low impurity level eliminated gel formation we saw with other suppliers. Drums arrived perfectly sealed and labeled—no delays in QA. Worth every penny."

Posted: 10 days ago

"Consistently on-time deliveries, fully compliant packaging, and excellent technical support. These drums have become our standard for CHDM transport."

Posted: 3 weeks ago

"Great chemical quality and drum durability. Only note: inner seal removal could be more user-friendly. Suggest including a pull-tab design in future versions."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.