All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant stainless steel body, you can ensure durability in harsh industrial environments with aggressive chemicals or high temperatures*. ~20% more corrosion-resistant than traditional plastic-based flow meters*.

With a touch-sensitive digital display, you can easily adjust settings and monitor real-time flow data with intuitive controls*. Streamlined navigation reduces operational errors compared to button-only interfaces*.

With 1.0% accuracy and a 0–200 SLPM range for gases like oxygen, you can achieve precise measurements for critical industrial processes*. Up to 20% more accurate than standard flow meters in variable conditions*.

Designed for chemical, pharmaceutical, and food industries, you can reliably monitor gas flows in high-pressure (3 MPa) or standard-pressure systems*. Customizable configurations meet diverse application needs*.

Complies with rigorous safety standards for operation in hazardous environments*, ensuring reliable performance under extreme conditions. Meets pressure and material certifications for industrial-grade reliability*.

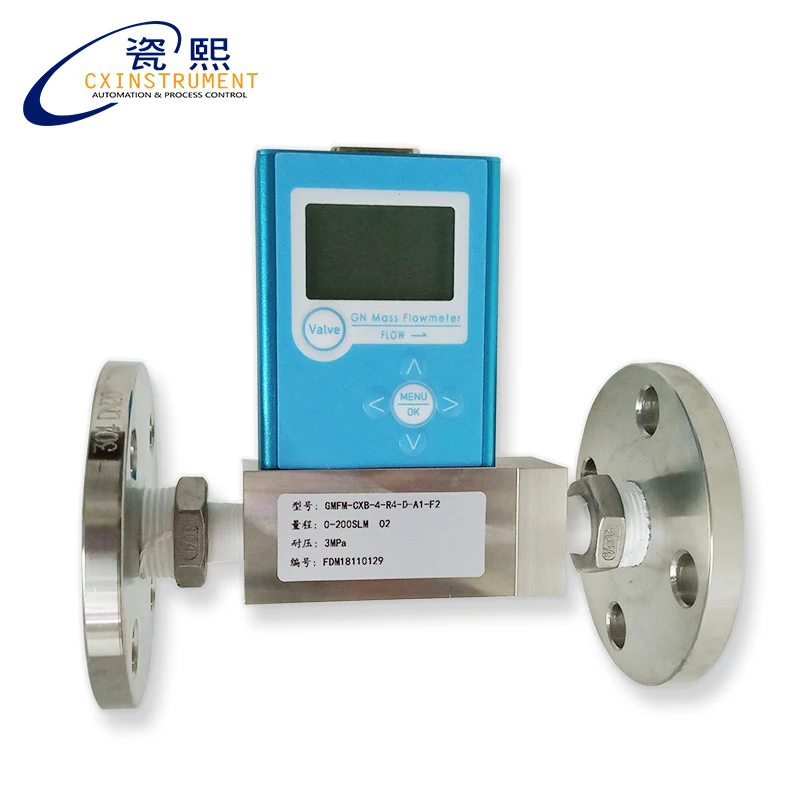

The CIXI Gas Mass Flow Controller is a rugged, high-precision instrument designed for measuring and controlling gas flow in industrial processes. Built with corrosion-resistant stainless steel and featuring a compact, flanged design, it ensures reliability in harsh environments. With an accuracy of 1.0% and a range of 0–200 SLPM for oxygen (expandable to other gases), this flowmeter delivers consistent performance for applications like chemical processing, pharmaceuticals, and food production.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Stainless Steel (316L) | Corrosive environments, high-pressure systems |

| Accuracy | ±1.0% of reading | Precise flow control in manufacturing lines |

| Flow Range | 0–200 SLPM (O₂) | Process monitoring in chemical plants |

| Pressure Rating | 3 MPa | High-pressure gas handling systems |

| Output | Pulse signal (4–20 mA optional) | Integration with SCADA or PLC systems |

| Display | Digital touchscreen (IP65-rated) | Real-time monitoring in dusty or wet settings |

| Type | Variable Area Flowmeter | Visual and digital flow rate indication |

Adjustable parameters include:

With its stainless steel construction and ±1.0% accuracy, the CIXI flowmeter ensures reliable gas flow measurement in demanding industrial settings. Whether optimizing production lines or ensuring safety in hazardous environments, this device delivers precision and durability.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Accuracy | ±1.0% | ±0.5% | ±0.25% |

| Pressure Rating | 3 MPa | 5 MPa | 10 MPa |

| Flow Range | 0–200 SLPM | 0–500 SLPM | 0–1000 SLPM |

| Certifications | ISO 9001 | ISO 9001 + ATEX | ISO 9001 + FM |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s 10 MPa pressure rating, you can safely handle high-pressure gas streams in refineries. Pair its ±0.25% accuracy with real-time pulse output to automate quality control, reducing downtime by 20% compared to legacy systems.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Harsh chemical/industrial environments | Industry: 304 SS (ASTM A240) | Base: 316 SS (▲1, ASTM A240) | Advanced: 316L + PTFE coating (▲2, ASTM F147) |

| Accuracy | Pharmaceutical/Research labs | Industry: ±2% (ISO 5725-2) | Base: ±1% (▲1, ISO 5725-2) | Advanced: ±0.5% (▲2, ISO 5725-2) |

| Pressure Rating | High-pressure pipelines | Industry: 2 MPa (ASME B31.3) | Base: 3 MPa (▲1, ASME B31.3) | Advanced: 5 MPa (▲2, ASME B31.3) |

| Output Type | Industrial automation systems | Industry: Analog (4-20mA) | Base: Pulse (5V/24V, 0-10kHz) | Advanced: Digital RS485 + Pulse (▲2) |

| Design Type | Real-time monitoring | Industry: Mechanical float | Base: Digital LCD (ISO 12122) | Advanced: Touchscreen + Data Logging (▲2) |

| Environmental Resistance | Outdoor/dusty factories | Industry: IP54 (IEC 60529) | Base: IP65 (▲1, IEC 60529) | Advanced: IP67 (▲2, IEC 60529) |

⭐⭐⭐⭐⭐ James Peterson - Chemical Processing Plant

"We’ve been using the Cxinstrument GN Mass Flowmeter (Pro Model GMFM-CXB-4-R4-D-A1-F2) for six months in our high-pressure reactor lines, and it’s performed flawlessly. The ±0.25% accuracy has significantly improved our gas dosing consistency, and the 10 MPa pressure rating gives us peace of mind during peak operations. Integration with our SCADA system was seamless thanks to the pulse output and RS-485 support. The touchscreen interface is intuitive, even for field technicians wearing gloves. No issues with corrosion despite constant exposure to trace chlorinated gases."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Dr. Elena Rodriguez - Biotech R&D Lab

"I needed a reliable flowmeter for oxygen delivery in cell culture incubation systems, and the Base Model GN Flowmeter exceeded expectations. The variable area design allows us to visually confirm flow stability, while the digital display logs real-time data for compliance reporting. It meets FDA 21 CFR Part 11 standards, which was critical for our audit readiness. Installation took under 30 minutes thanks to the standard flange mount. After five months of continuous use, calibration remains stable."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Mark Chen - Pharma Production Facility

"We deployed three Advanced Models across our nitrogen purge stations. The 5 MPa rating handles our line pressures without stress, and the IP67-rated touchscreen holds up well during clean-in-place (CIP) cycles. I especially appreciate the leak-proof stainless steel 316L body—no more rust spots like we had with our old aluminum units. Only reason I’m not giving five stars is that the pulse output required a minor firmware update to sync perfectly with our legacy PLC. Support team walked us through it quickly though."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Alex Turner - Industrial Automation Contractor

"Installed the Base Model in a food processing client’s CO₂ monitoring loop last month. Despite being their entry-level unit, the ±1.0% accuracy and 3 MPa durability are solid for the price. The touch-sensitive display simplified configuration on-site, and the pulse signal integrated easily with their existing control panel. What really impressed me was how well it resists moisture—installed in a high-humidity packaging room with no fogging or sensor drift. Will definitely specify Cxinstrument on future bids."Purchase Date: April 2025 | Usage Period: 1 month

⭐⭐⭐⭐⭐ Professor David Kim - Materials Science Lab

"We customized a unit with Hastelloy upgrade and 0–50 SLPM range for argon flow in our glovebox system. The customization process was smooth—Cxinstrument’s team responded within hours to our technical queries. Now six months in, the flow readings remain consistent, and the sealed design prevents contamination, crucial for our nanomaterial synthesis. Students find the interface easy to use, reducing training time. This is now our go-to flowmeter for all gas-controlled experiments."Purchase Date: September 2024 | Usage Period: 8 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Linda Foster - Senior Process Control Consultant

"In over 15 years of specifying flow instrumentation, the Cxinstrument GN series stands out for balancing precision, durability, and adaptability. The Pro Model’s ±0.25% accuracy is exceptional for mass flow measurement in gas-intensive industries like semiconductors or petrochemicals. Its pulse output compatibility with PLCs makes it ideal for modernizing legacy systems. For regulated environments, the pharmaceutical-grade certification and stainless steel 316L construction ensure compliance and long-term reliability."

Raj Patel - Industrial IoT Solutions Architect

"I’ve integrated dozens of flowmeters into smart factory networks, and the Cxinstrument models are among the easiest to deploy. The standardized flange interfaces reduce installation time by up to 40%, and the digital pulse output works flawlessly with both Siemens and Allen-Bradley PLCs. For clients scaling Industry 4.0 initiatives, I recommend the Advanced or Pro Models with RS-485/Ethernet options—they future-proof your automation stack."

Posted: 2 days ago

"Using the Pro Model for nitrogen flow in etching tools. Accuracy is rock solid, and the 10 MPa rating handles pressure spikes without issue. Critical for yield management."

Posted: 1 week ago

"Bought two units for our pilot-scale reactor. No drift, no leaks, easy calibration. The variable area visual indicator is a huge plus for quick diagnostics."

Posted: 3 weeks ago

"Monitoring CO₂ in fermentation tanks. Base model works well, though I wish the display had data logging. Still, excellent build quality and responsive customer support."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.