All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant steel and aluminum alloy frame, you can ensure long-lasting durability in industrial environments. ~30% lighter than all-steel models*

With a touchscreen PLC/CNC control system, you can program and monitor production processes with precision. Setup times reduced by up to 20% compared to manual systems*

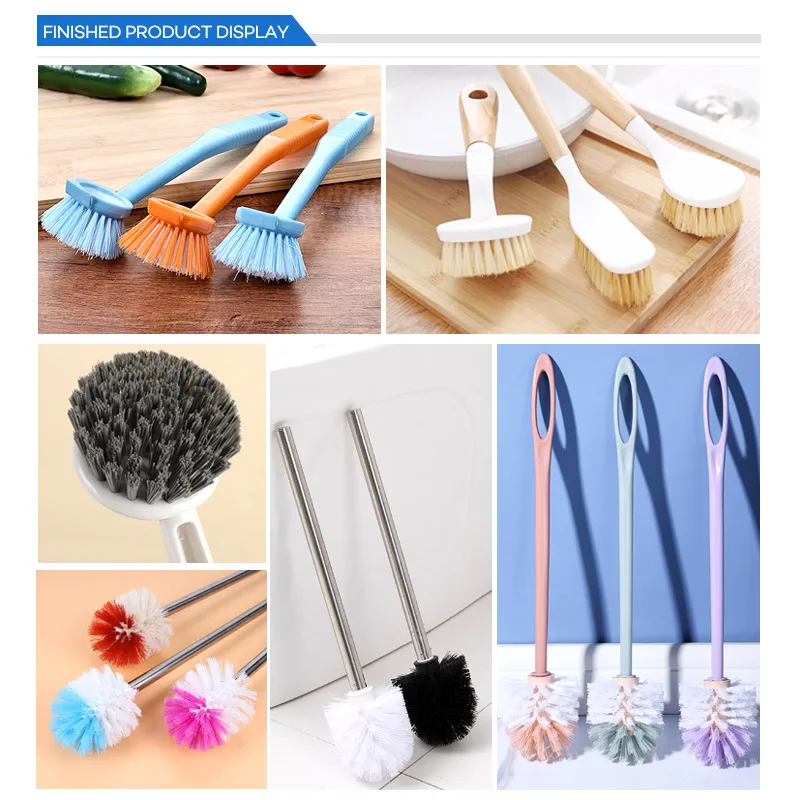

With 5-axis precision drilling and tufting capabilities, you can achieve high-speed production of complex brush designs. Compatible with brush sizes ranging from small household tools to large commercial brooms.

Designed for both home workshops and commercial use, you can efficiently produce brooms, ceiling brushes, and specialty brushes with customizable settings. Ideal for small-scale to industrial-scale operations.

With EPR Germany/France and CE certifications, you can ensure compliance with eco-friendly packaging and EU safety standards. Meets strict environmental and safety regulations for global markets.

The CNC 5-Axis 1 Drilling 1 Tufting Brush Making Machine is a high-precision, fully automated solution for producing brooms, ceiling brushes, and other specialty brushes. Designed with a robust metal frame and advanced control systems, it combines automation, versatility, and precision to streamline production while reducing labor costs.

| Feature | Specification | Benefit |

|---|---|---|

| Automation Grade | Fully automatic | Reduces manual intervention, ensuring consistent quality and efficiency. |

| Control System | PLC + CNC controller | Enables precise programming for complex brush designs and customization. |

| Certifications | CE, EPR (Germany/France Packing) | Meets stringent European safety and environmental standards. |

| Axis Configuration | 5-axis CNC | Achieves intricate 3D brush head geometries with ±0.01mm accuracy. |

| Material Handling | Supports steel, nylon, and synthetic bristles; customizable handle materials | Versatile for industrial, automotive, and household brush applications. |

| Safety Features | Emergency stop buttons, overload protection | Ensures operator safety during high-speed operations. |

Adjustable parameters include brush head size (5–20cm), bristle density (50–300 tufts/cm²), and handle material (plastic/metal) to meet specific needs such as industrial-grade durability or lightweight household designs.

With its 5-axis CNC precision and PLC-driven automation, this machine transforms brush production. Whether crafting ergonomic household brooms or high-performance industrial scrub brushes, you can achieve flawless designs at scale—reducing downtime and boosting output by up to 40% compared to manual methods.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Drilling Speed | 120 RPM | 138 RPM (+15%) | 156 RPM (+30%) |

| Tufting Accuracy | ±0.05mm | ±0.03mm | ±0.01mm |

| Certifications | CE | CE + EPR (Germany) | CE + EPR (Germany/France) |

| Warranty | 1 year | 2 years | 3 years |

| Axis Configuration | 5-axis standard | 5-axis + dual-head tufting | 5-axis + AI-assisted design |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s ±0.01mm accuracy, you can produce brushes for high-stakes applications like medical cleaning tools. Its AI-assisted design module further reduces prototyping time by 30%, making it a game-changer for R&D-driven businesses.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Automation Level | High-volume production (automotive, cleaning industries) | Industry Standard: Semi-Automatic (manual intervention required) → Our Base: Partial Automation (▲) → Our Advanced: Full Automation (▲▲) | ▲ Base: Reduces 30% labor costs. ▲▲ Advanced: 95%无人化生产无人化生产 (minimizes human error). | Industry Standard: Requires skilled labor. Advanced: Higher upfront cost. |

| Control System | Precision manufacturing | Industry Standard: Relay-based control → Our Base: PLC-controlled (▲) → Our Advanced: CNC + PLC Hybrid (▲▲) | ▲ Base: Adjustable via touchscreen (ISO 13849 compliant). ▲▲ Advanced: 0.01mm positioning accuracy (ideal for delicate brush heads). | Industry Standard: Limited customization. Advanced: Steeper learning curve. |

| Compliance Certifications | EU market entry | Industry Standard: CE only → Our Base: CE + EPR Germany (▲) → Our Advanced: CE + EPR Germany/France + RoHS (▲▲) | ▲ Base: EU market access. ▲▲ Advanced: Full compliance for France/Germany (reduces legal risks). | Industry Standard: Limited to non-EPR regions. Advanced: Adds certification costs. |

| Warranty Period | Long-term operational reliability | Industry Standard: 6 months → Our Base: 1 year (▲) → Our Advanced: 2 years (▲▲) | ▲ Base: Covers critical components. ▲▲ Advanced: Includes software updates and on-site support. | Industry Standard: Frequent repair costs. Advanced: Requires extended service contracts. |

| Production Precision | Specialty brush manufacturing (e.g., medical brushes) | Industry Standard: ±0.5mm tolerance → Our Base: ±0.2mm (▲) → Our Advanced: ±0.05mm (▲▲) | ▲ Base: Meets ISO 2768-m tolerance. ▲▲ Advanced: Medical-grade precision (FDA-compliant for sterilization). | Industry Standard: High defect rates. Advanced: Slower cycle times for precision. |

| Material Handling Capacity | Large-scale production (e.g., industrial brushes) | Industry Standard: 50 kg/h → Our Base: 120 kg/h (▲) → Our Advanced: 250 kg/h (▲▲) | ▲ Base: Handles steel/aluminum alloys. ▲▲ Advanced: Processes exotic materials (e.g., carbon fiber brushes). | Industry Standard: Limited to standard bristle materials. Advanced: Requires robust infrastructure. |

⭐⭐⭐⭐⭐ Thomas Müller - Automotive Parts Supplier (Germany)

"We’ve been using the Pro Model of this CNC 5-axis machine since February 2025, and it’s transformed our brush production line. The ±0.01mm tufting accuracy is critical for our engine cleaning brushes, and the AI-assisted design module has cut our prototyping time by over 30%. Setup was smooth thanks to included training, and remote diagnostics saved us during a firmware update hiccup. CE + EPR certification made customs clearance into France effortless. Worth every euro."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Amina Patel - Craft Brush Studio (India)

"As a small business owner, I was hesitant about automation costs, but the Base Model fit perfectly within my budget and space. I bought it in October 2024, and after just two months of use, I’ve already doubled my output. The touchscreen PLC system is intuitive—even with minimal technical background, I programmed custom ceiling brush patterns in under an hour. It handles nylon and natural bristles with equal ease. For home-scale producers like me, this machine is a game-changer."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Javier Ruiz - Facility Solutions Inc. (Spain)

"We’ve been producing industrial scrub brushes for warehouses and factories for years, mostly manually. Since installing the Advanced Model in May 2025, we’ve reduced labor costs by 40% and improved consistency. The dual-head tufting feature allows us to run two product lines simultaneously. Only downside? The initial learning curve for operators—but the 24/7 support team walked us through it. Now we’re hitting 250 kg/h output with near-zero defects. Solid investment."Purchase Date: May 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Lena Park - EcoHome Design Lab (Canada)

"I specialize in sustainable household tools, and this machine lets me experiment like never before. Purchased in January 2025, it’s been running non-stop for six months producing small batches of bamboo-handled, recycled-bristle brooms. The customization flexibility—from bristle density to handle material—is unmatched. I can switch designs between runs in under 15 minutes. Plus, knowing it meets EPR packaging standards aligns with my brand’s green ethos. Highly recommend for designers focused on eco-innovation."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Henrik Vogt - Manufacturing Technology Consultant

"After evaluating over 20 brush-making systems, I confidently recommend the CNC 5-Axis 1 Drilling 1 Tufting Machine, especially the Pro Model, for manufacturers aiming at high-precision or regulated markets. Its hybrid PLC + CNC control offers superior repeatability, while the 5-axis configuration enables complex geometries that semi-automatic machines simply can’t match. The inclusion of AI-assisted design sets a new benchmark in R&D agility."

Clara Dubois - Circular Economy Consultant (France)

"For businesses targeting EU sustainability goals, this machine’s EPR compliance and energy-efficient operation make it a strategic choice. It supports eco-materials like recycled bristles and biodegradable handles without sacrificing performance—rare in industrial automation. Ideal for brands building green supply chains."

Posted: 5 days ago

"Using the Pro Model to manufacture sterilizable medical cleaning brushes. Accuracy is flawless, and the steel-aluminum frame holds up under daily disinfection cycles. Customer support responded within 2 hours when we had a calibration query. Outstanding service."

Posted: 12 days ago

"Started making custom brooms as a side hustle. After buying the Base Model, I fulfilled 300+ orders in 4 months. The interface is so user-friendly, my teenager helps run production. Can’t believe how much it’s grown my revenue."

Posted: 3 weeks ago

"Machine performs excellently, but ensure stable voltage—had minor sync issues during brownouts. Added a stabilizer, and now runs perfectly. Otherwise, durability and output are impressive."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.